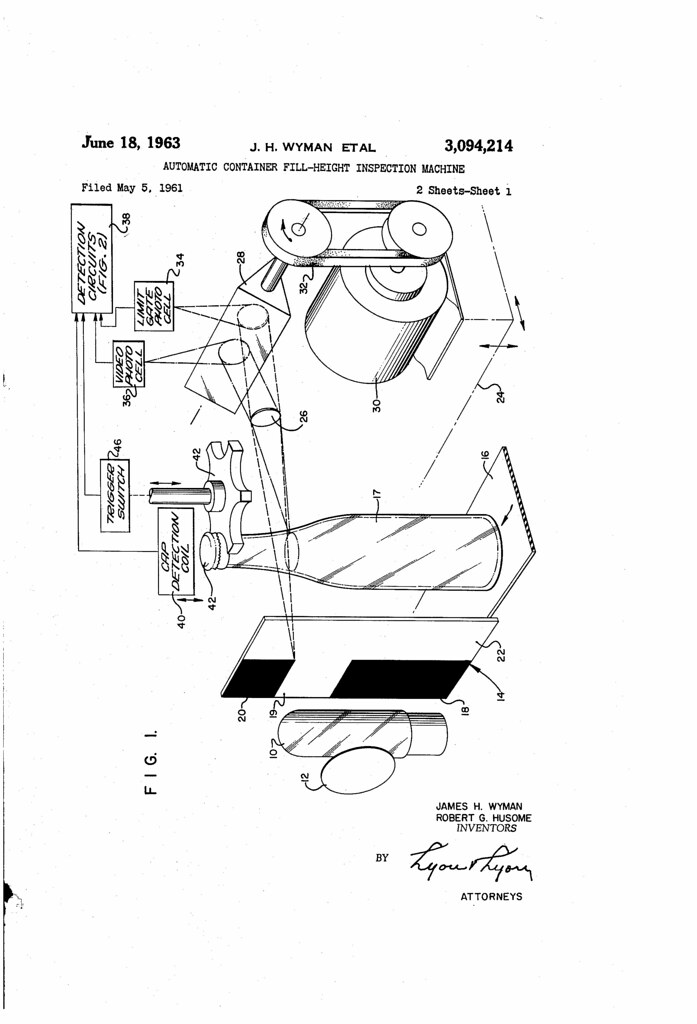

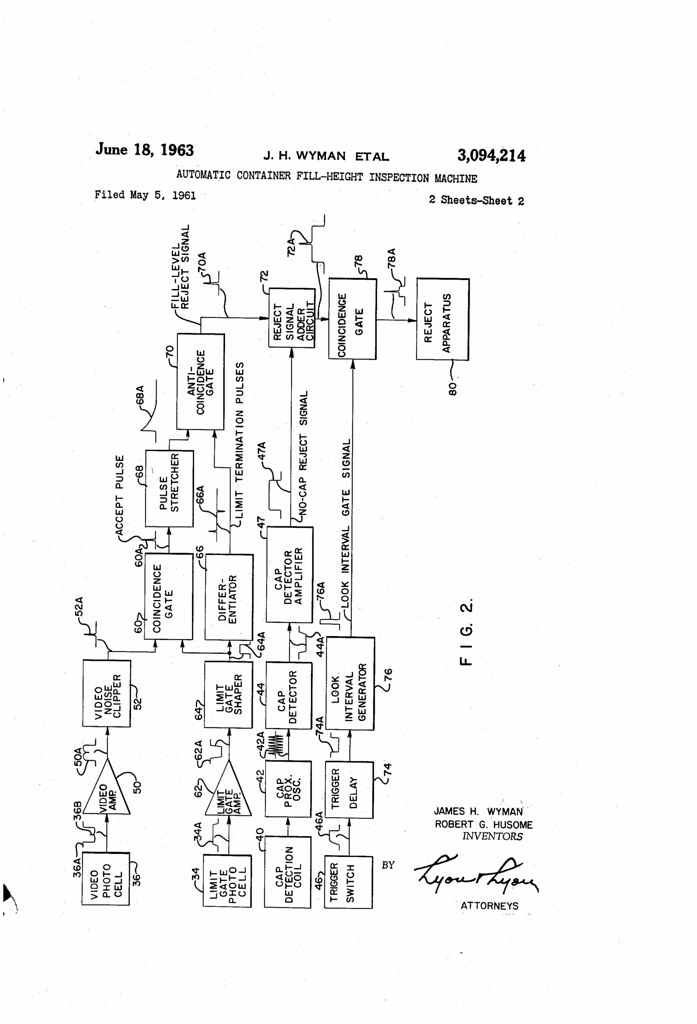

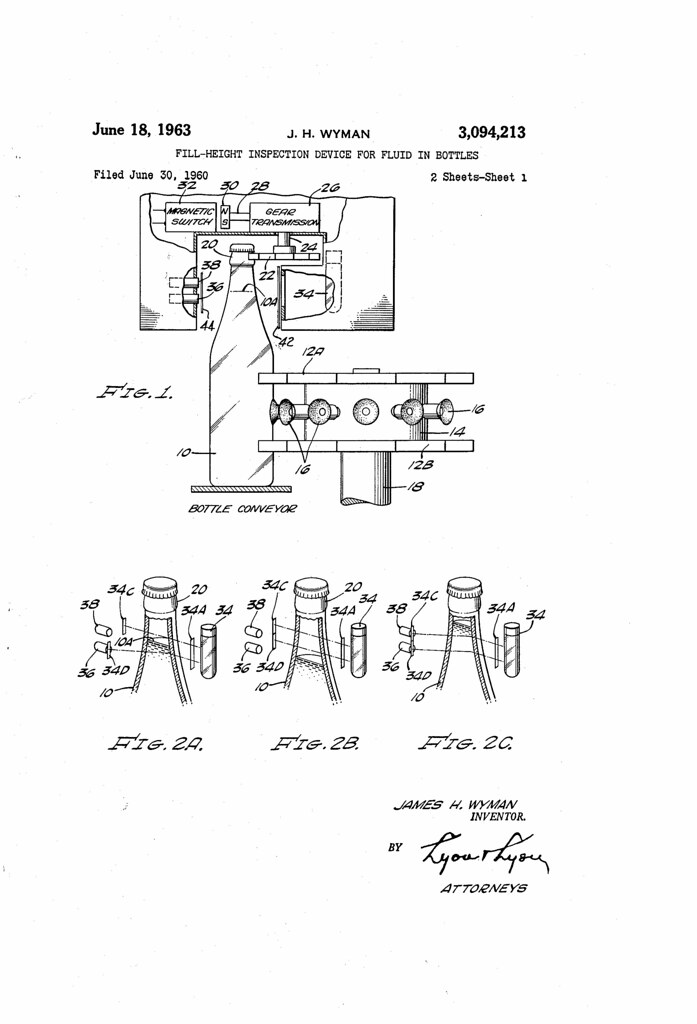

Today in 1895, US Patent 3094213 A and US Patent 3094214 A was issued, both inventions of James H. Wyman, with the second also by Robert G. Husome, for their “Fill-Height Inspection Device For Fluid In Bottles” and “Automatic Container Fill-Height Inspection Machine.” There’s no Abstract for either, though they’re described this way in the application:

This invention relates to inspection apparatus of the type used to deter-mine whether a transparent container, such as a bottle, has been filled to the proper height with a liquid, and, more particularly, to improvements therein.

The requirement that the volume of beverage in a bottle correspond to the volume specified on the label on the bottle is a legal one. Good customer relations also provide more incentive to a bottler of liquids which require him to make sure that the contents of the bottle are as specified. On the other hand, should more than the specified amount of liquid be poured into the bottles, the bottler suffers an economic loss. Thus, a number of different systems have been proposed which inspect translucent containers, such as bottles, to determine whether the fill-height of the bottle is proper. These systems usually apply radiation on one side of the bottle and a detector on the other side of the bottle in the region of the bottle wherein desired fill-height occurs. However, due to various factors, such as the differences in bottle thickness, bottle color, variations in beverage color, as well as the presence of foam in many beverages, none of the heretofore-produced systems have proven consistently satisfactory.

An object of this invention is to provide a fill-height inspection system which is not adversely aifected by variations in bottle thickness or color.

Another object of this invention is the provision of a fill-height inspection system which is not adversely affected by differences in beverage color or the presence of foam.

Yet another object of the present invention is the provision of a novel and unique fill-height inspection system.

These and other objects of the invention are achieved by taking advantage of the fact that light is refracted or bent at ‘a unique angle by the liquid and its container. Thus, if a photocell is positioned on one side of a container so that no illumination from a light source can reach that photocell, unless it is refracted by the liquid in the container, a positive arrangement for detecting the fill-height of the liquid in the container may be obtained. The photocell is positioned adjacent the container at a level just below the minimum acceptable level. Similarly, to determine whether a container has been overfilled, a photocell may be positioned adjacent the container just above the maximum desired fill-height level, to be illuminated only by light which is refracted by the liquid in the bottle.

This invention relates to automatic fill-height inspection machines and, more particularly, to an improved arrangement for determining that a translucent container has been filled to the proper level.

Presently known automatic fill-height machines for photoelectrically inspecting a translucent container are not completely reliable, as a result of difficulties experienced with different colored bottles or bottles of varying opacity, thickness, or even in view of the fact that some liquids which are carbonated, such as beer, will have a foam at the top of the liquid which can provide a false signal as to the actual level to which the container is filled. Another difficulty which arises is that the prior systems are substantially limited to use with only one size of a container. If a production run of a different container size or even different fill-height requirements is desired, a considerable realignment of the fill height inspection apparatus parameters is required. A further limitation of prior systems is that they may be applicable only to translucent liquids.

An object of this invention is the provision of a reliable fill-height inspection apparatus.

Another object of this invention is the provision of a novel and useful fill-height inspection apparatus.

Yet another object of this invention is the provision of a fill height inspection apparatus which is easily adjustable for inspecting containers of different sizes.

Yet another object of this invention is to provide fill height inspection capability for opaque liquids, translucent liquids with foam on top, or solid (e.g., granular or powdered) materials in translucent containers.