![]()

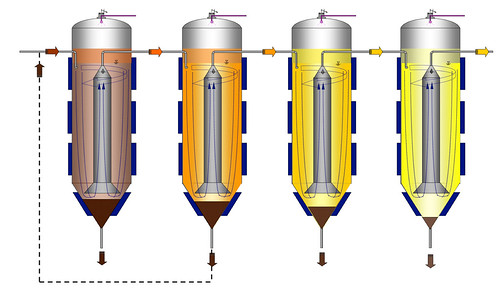

I just stumbled upon this interesting article from May in Phys.Org entitled More sustainable way to brew beer: Non-stop fermentation saves resources. It details efforts by researchers at the Technische Universität München to develop “a fermentation process that takes place in stages over a number of interconnected tanks. The tank system can be operated continuously over a period of several months, which leads to an energy reduction. The new method also promises significant resource efficiency gains.”

They talk about the advantages of such a system. “With this new process, yeast and other sedimented substances can be fractionized and re-used if required, and “unlike the conventional system[s], the brewers can fill and empty the tanks continuously from the top part of the tanks. The bottom connection of the tank can hence be used to discharge yeast cells and other particles.”

Lead researcher, Konrad Müller-Auffermann explains how “Continuous operation makes the fermentation plant more efficient. ‘This new method reduces the incidence of energy peaks, so that breweries will be able to save on electricity. In addition, less beer will be lost — and breweries can save water and cleaning detergents.'”

So far, so good. It sounds interesting, but here’s where they lost me. “Brewers have been juggling with the dream of turning the classical batch fermentation into a continuous process for over 100 years. In all this time, however, no one has managed to develop a widely applied industrial concept.”

Um, maybe somebody with more technical expertise can explain this to me, but New Zealanders (and possibly the Australians) have been using what they call “continuous fermentation” since 1953, and at least one brewery is still using it today. I did a sidebar about Continuous Fermentation for All About Beer magazine in 2008.

One of New Zealand’s most interesting contributions to brewing sciences is the process known as continuous fermentation. This process was patented in 1953 by Morton Coutts, whose family had been involved in brewing since the 19th century. His father founded the Waitemata Brewery, which eventually become DB Breweries.

Essentially, Coutts created a “wort stabilization process” that made the wort more consistent and clear, and then separated the main functions of the yeast into two stages. In the first, yeast grew, and in the second, it fermented. By splitting these two functions, Coutts created a “continuous flow,” so brewers could continually add raw materials to the first stage, and draw off a steady supply of finished beer from the second thus allowing the brewery to run constantly.

It also shortened the brewing process by as much as several weeks. Recognizing the economic advantages to continuous fermentation, Lion and DB worked together jointly to develop a practical way to use the method in a commercial brewery, opening the world’s first continuous fermentation brewery in 1957 in Palmerston North, a town in the south central part of the North Island.

Continuous fermentation works best in a brewery making only one style of beer, because it’s difficult to stop the process and start up again with a new beer. As a result, Lion largely abandoned continuous fermentation in the 1980s in order to brew a wider variety of styles, while DB continues to use the method, as do several other large breweries around the world, such as Guinness.

The University of Aukland’s Business History Project has a good overview on Morton Coutts, father of continuous fermentation. You can also read more at Alcohol Fuels and Ken & Dot’s Allsorts.

So nothing against the German effort at non-stop fermentation. It looks interesting and innovative. But it doesn’t seem all that different from continuous fermentation that was invented sixty years ago. Maybe there’s a subtle or technical difference I’m missing, but they don’t even mention being aware of it when they insist people have been trying to figure out this problem for over a century, which seems a little strange. So while they’re understandably excited about their discovery, I wish they’d acknowledge Coutts. Or am I missing something?

I am not a Brewer… but I worked for Miller MKE HQ (Mostly in Marketing) from 1980 to 1993 … sustainable brewing sounds Great.. This strikes me me like the quest for a perpetual motion machine .. : ) MORE POWER to them IF it yields Real, Good Beer.

I would agree w/Jay that it would work best with one style of beer – but it has 2 inherent problems:

1. Yeast has a re(cycling/generation) limit before it becomes impotent; &

2. The system must be 100% closed, w/no leaks (meaning .pipes & no hoses) – any “air” leak might cause infection/infuse airborne yeast to contribute “off” flavors. Further, there are seals/washers in the piping connections, which eventually wear out – which means complete shutdown for maintenance.

The only way I could see it being workable on a large scale is if there’s a way to “IV” fresh yeast into what’s drawn off &/or filter out the dead cells. Even then, the brewery would need at least 2 such systems – the tanks & lines need residual cleanout every so often anyway. Great in theory; the Kiwi brewery found out eventually that it didn’t make economic sense (before energy conservation hit the collective radar).

Good point about the limit to the amount of time the yeast will remain viable. The solution would be to separately add a certain wt% of fresh yeast to the first fermenter or to the a hold up vessel prior to the fermenter. The percentage of fresh yeast would need to be tuned so that enough new yeast is added to replace deactivated/dead cells in the recycled stream. With a perfect recipe and perfect sanitation, this setup could theoretically run for a very long time. Considering traditional fermenters need to be sanitized after each batch, this continuous process could go much longer between cleaning cycles if it is air tight and thoroughly sanatized.

Of course, eventually the system will have to be shut down for cleaning and maintenance. Having a second system to run during the downtime would essentially double the equipment cost since there will be two of everything. Another solution would be to plan for the downtime by sizing the fermentation system so that in runs a just a bit quicker than the wort is produced. During downtime, the wort that is made would be accumulated in a hold-up vessel and stored until the fementer is back online. Once the fermenter is running it would outpace wort production, and the holdup vessel would slowly drain until the next cleaning.

DB CF plants are always in doubles so one set is maintained while the other is operating. There are tales in the industry here of brewery worker strikes and wort sitting in the CF plant for weeks and then the plant being restarted and the beer being fine. Myth or truth who knows.

The key issue with CF is it produces pretty shitty tasting beer. Estery and amyl acetate packed.

I was the last manager in charge of a DB style continuous fermenter in Europe – sited at Drybroughs Brewery in Edinburgh (part of WMTB) – I was told to close it down in 1982. Sad to see it go – it was very dependable and the beer flavour was mostly indistinguishable from the same beer produced from the batch fermenters.

I have since been present at fermentation lectures where it was stated that continuous fermentation never really worked! Well I am able to say that using the control systems available in the 1960s through to the 1980s – it did work so it should be even more successful with today’s technology.