Today in 1951, US Patent 2564163 A was issued, an invention of Jean Emile Lucien Leperre, for his “Receptacle With Elastic Bag Insert and System For Filling and Emptying the Same.” There’s no Abstract, although in the description it includes these claims:

it is submitted between the brewery and the consumer. Numerous laboratory experiments have shown that beer samples removed with all the required care directly from the brewery tanks keep well. The case is no longer the same when the beer has passed through different casks and various drawing means.

The different causes of contamination are as follows:

In the case of wooden casks, these casks are always infected by the beer dregs remaining inside the casks emptied at the retailers. Once the cask is contaminated it is not possible to sterilize it again completely and the infection is continued by each new filling with beer.

Laboratory experiments of a very complete character have shown that when it is possible to superficially sterilize a cask, the infection begins again as soon as the cask has been put again under pressure.

It is a well-known fact that the dissolution of air in beer is also a cause of the lack of stability of said beer.

Moreover, the beer containers of the drawing 01! means where the beer has always a tendency to become hot. and to lose a part of its carbonic gas, the return into said containers of the froth and of the counter-pressure gases, as well as the presence of the plunging tubes of the drawing oil means, are several of the factors causing alteration of the beer.

As to the dealing out of the beer, it is a known fact that as long as a cask is not broken into, the beer retains generally its quality but once it has begun being dealt out the beer loses in a few hours most of its quality.

On the other hand for breaking into his cask. the retailer introduces into his beer a plunging tube which has generally been left about in the cellar and at the same time he drives into it the stopper of the cask which is unavoidably contaminated.

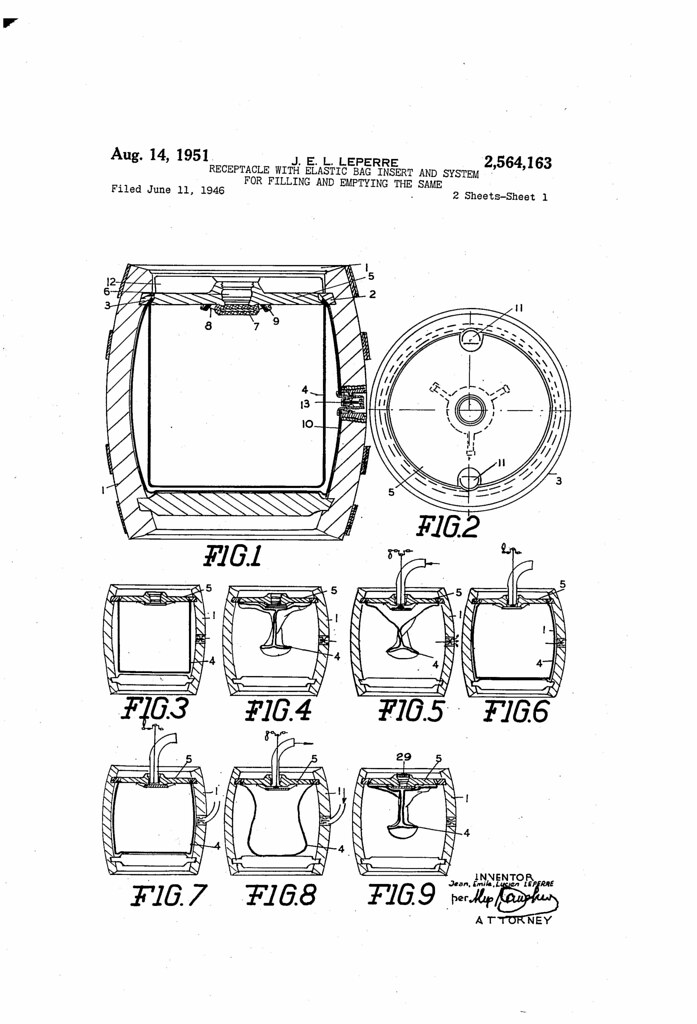

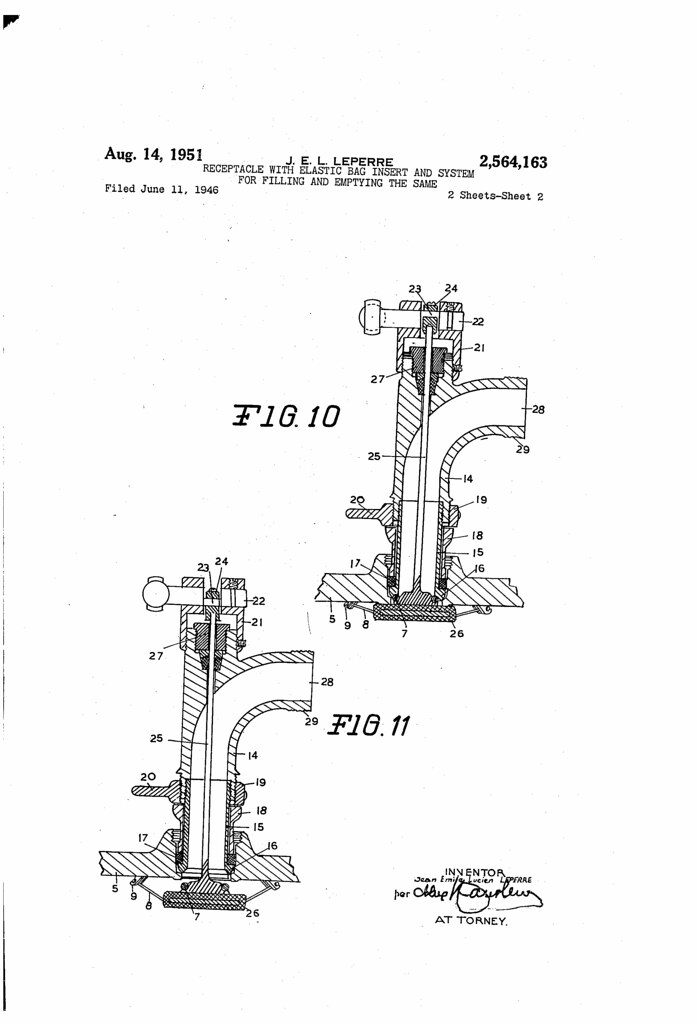

The present invention has for its object to remove these multiple drawbacks, and it comprises chiefly a special container having a yielding receiver mounted inside a rigid receiver with means being provided for allowing the liquid under pressure to enter inside the inner yielding receiver and also for allowing a counter-pressure fluid to be introduced between this inner yielding receiver and the outer rigid receiver.

A further characteristic feature of the invention consists in that the recess formed by the inner yielding receiver is reduced to zero for the filling of the cask with beer under pressure so that said recess is consequently completely emptied of its air, this being produced by a counter-pressure exerted between said receiver and the rigid outer receiver, the former increasing gradually in volume through the introduction of beer under pressure inside it while said counter-pressure gas progressively escapes from the outside of the yielding receiver.

According to a still further feature of the invention, there is provided a rigid receiver containing a yielding removable fluid-tight receiver, pouch or pocket into which the liquid under pressure is introduced while means are provided firstly for allowing the latter to communicate with the outside and secondly for adjusting the pressure of the fluid contained between the two receivers.