Today in 1965, US Patent 3223062 A was issued, an invention of Harry Mulder, assigned to the Firestone Tire & Rubber Co., for his “Bung Patch Plate Assembly Method.” Here’s the Abstract:

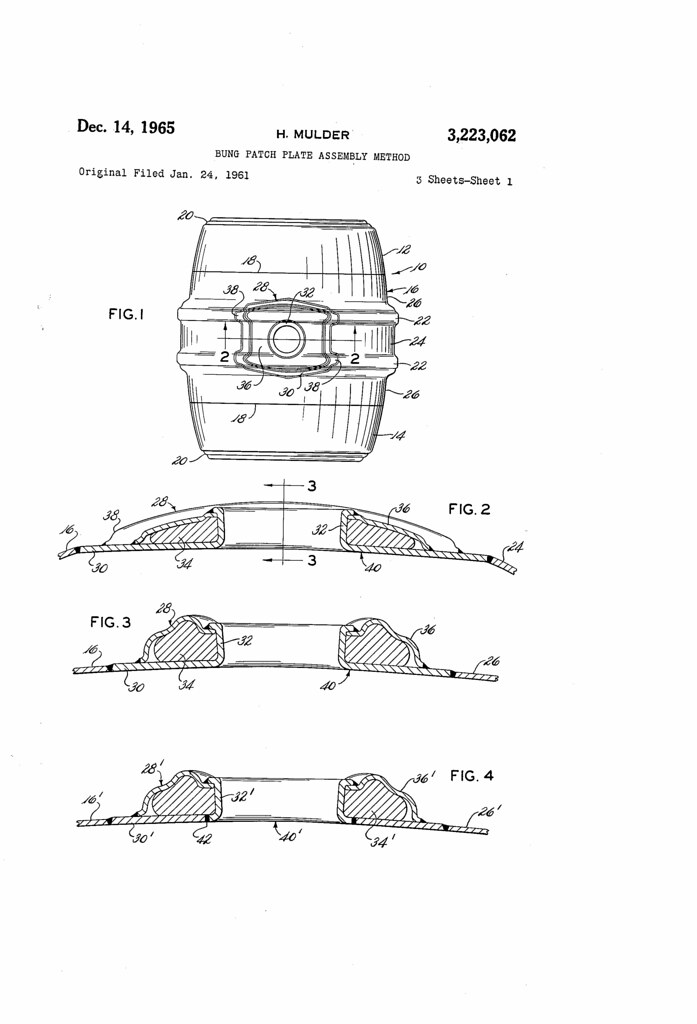

This invention relates to containers, such as single-walled metal beer barrels, and the method of construction of the same.

The primary object of the invention is to provide an improved patch plate assembly for reinforcing and protecting the bung opening.

One of the problems involved in the construction of a container having a single-walled thickness is to provide a protecting structure about the bung opening, through which the container may be cleaned, filled and drained. The bung opening also must be capable of withstanding the force exerted when the bung plug is driven therein.

Generally, bung patch plate assemblies around bung openings in beer barrels, for example, involve two separate walls or thicknesses of metal separated by a space, the latter being completely enclosed by the two metal walls. Normally, there is no opening leading to this space for the ingress or egress of liquids or gases. The two metal walls enclosing this space are sealed by the use of welds.

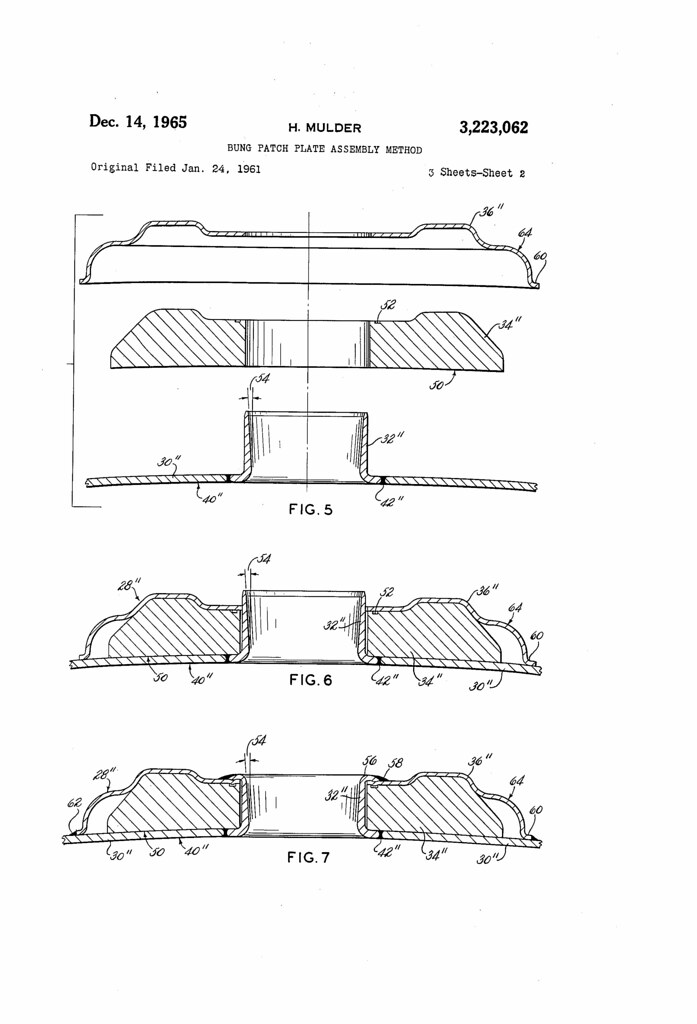

One or more of these welds, in prior art barrels are generally located so as to be in a position between the sealed space and the barrel cavity with the inner patch plate about the bung opening welded at its peripheral edges to the inside surfaces of the container. During the cleaning stages and prior to the filling of a single-walled metal beer barrel, it is inserted in a mold, filled with water and subjected to a pressure of approximately 900 lbs. per square inch in order to remove all dents to insure an exact volumetric capacity, and so that the barrel itself will present a more pleasing appearance. Therefore, it is not unusual that in the course of time and through other hard use, these welds sometimes become cracked.

When a crack occurs in a weld in the area between the enclosed space and barrel cavity, some of the beverage seeps into the enclosed space. The entrapped liquid decomposes and becomes extremely odious. When the containers or beer barrels are washed they are subjected to temperatures which vary greatly, the varying temperatures causing pressure changes within the enclosed space. These pressure changes cause seepages of the decomposed liquid from the space out of the crack in the weld( s) which seepages are not only offensive in smell and taste, but also are detrimental to the maintenance of high health standards.

The detection of a crack in a weld occurring in a location between the enclosed space and the beverage cavity presented a further problem. The crack could not be seen and usually the first time anyone knew of its presence would be because of the noxious smell. To repair such a crack it was necessary that one of the end shells be sawed off, the weld repaired from the inside of the barrel, and then the end shell placed back into position and secured by a fusion welding process. This was not only expensive, but was also time consuming in that the barrel generally had to be sent back to the place of manufacture or some other place where there were available facilities for so cutting and re-welding.

One of the objects of the invention is to avoid the above-mentioned problems by constructing the bung patch plate assembly so that there are no welds between the enclosed space and the beverage cavity.

Another object is to arrange all of the welds of the patch plate assembly on the outside of the container so that, in the event a weld does crack, the crack may be readily seen and repaired.

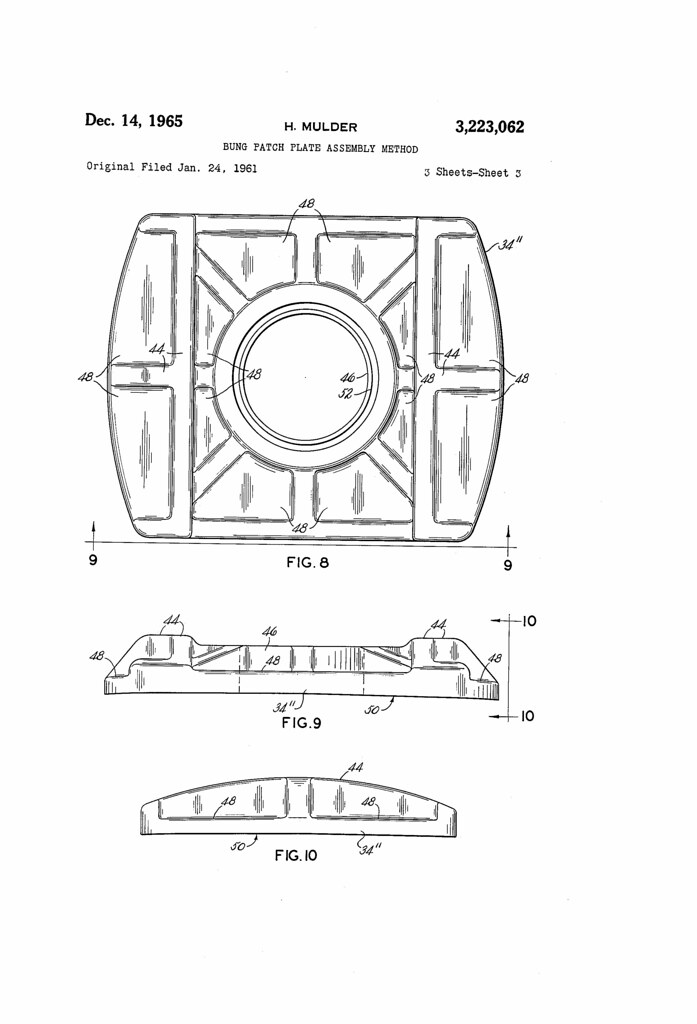

A further object of the invention is to provide a support within the space enclosed by the two metal walls designed to distribute over a wider area the stresses and strains occurring around the bung opening.