Today in 1968, US Patent 3370720 A was issued, an invention of Ernst R. Schickle, assigned to Rheingold Breweries Inc., for his “Keg Handling System.” There’s no Abstract, although in the description it includes this summary:

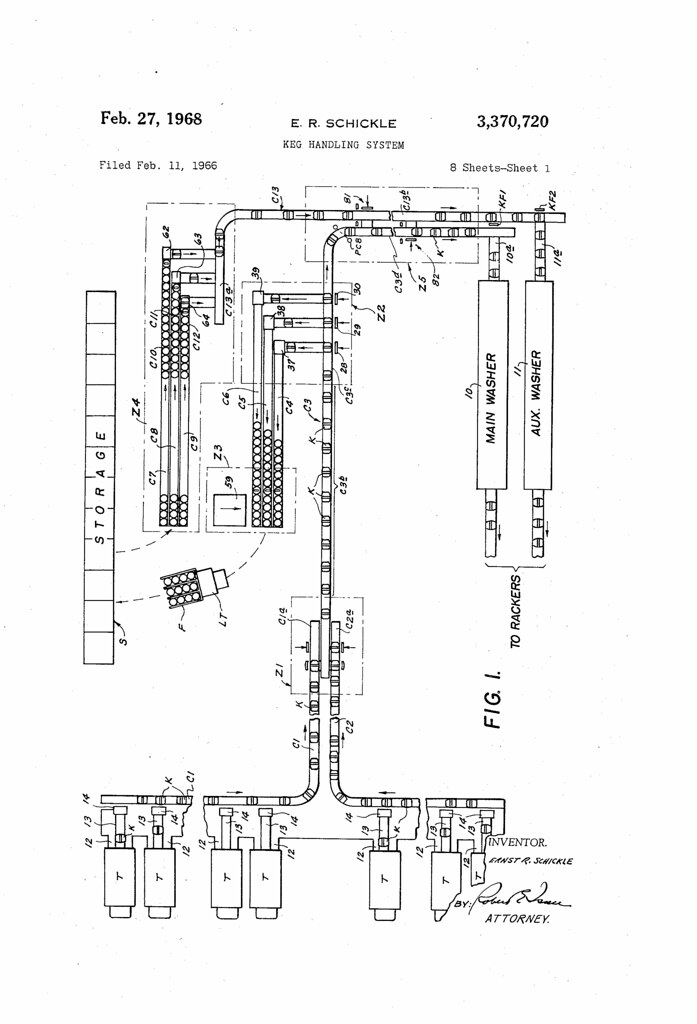

Since kegs for draught beer are relatively costly, the empty kegs are returned to the brewery and there washed or cleaned prior to being refilled with beer for distribution to taverns and the like. In order to maintain the sterility of the kegs, the cleaned kegs cannot be stored, but rather must be conveyed directly from the washing apparatus to the rackers at which the kegs are filled. Thus, the efficient utilization of the washing apparatus and the rackers requires that, during the filling of kegs, there be available to the keg washing apparatus a continuously adequate supply of empty kegs to permit the operation of the washing apparatus at its optimum capacity which corresponds substantially to the rate at which the cleaned kegs can be filled by the rackers. However, the delivery trucks return the empty kegs in varying quantities to the brewery during limited and random time periods and such trucks must be unloaded, reloaded with filled kegs and moved from the loading docks or bays as quickly as possible. Thus, the random times during which varying quantities of empty kegs are returned to the brewery cannot be correlated with the necessary continuous keg washing and refilling operations so that, at certain periods, it is necessary to store varying quantities of the empty kegs as they are returned, and thereafter to remove empty kegs from storage in order to maintain a continuously adequate supply thereof to the washing apparatus. Due to the number and bulk of the kegs involved, such storage and handling of the empty kegs give n’se to very serious problems, as concerns the operating expenses of the brewery.

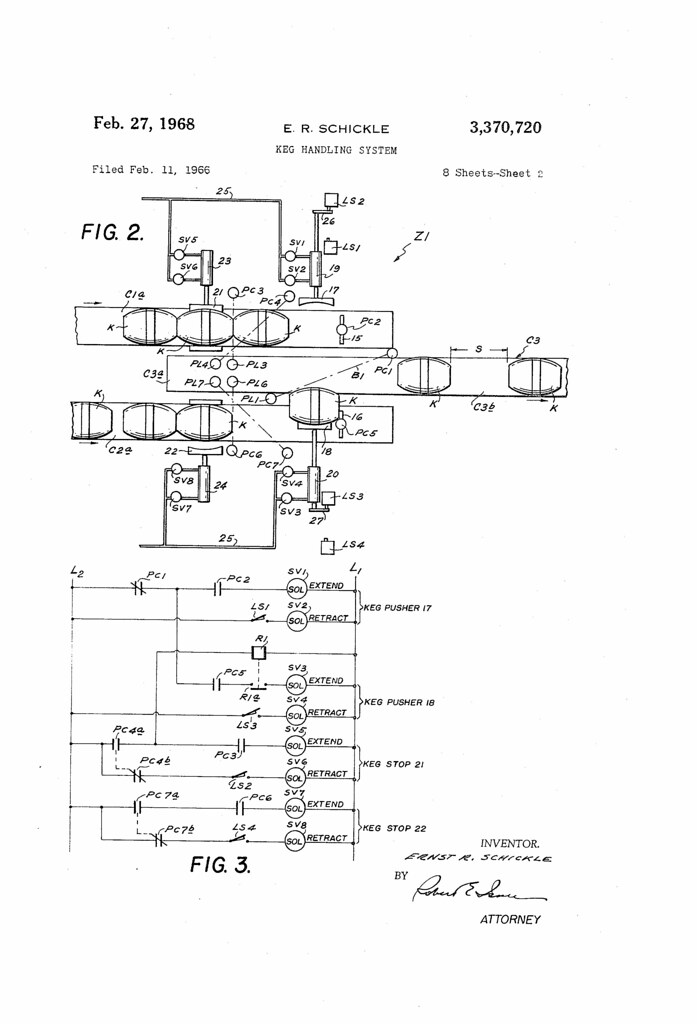

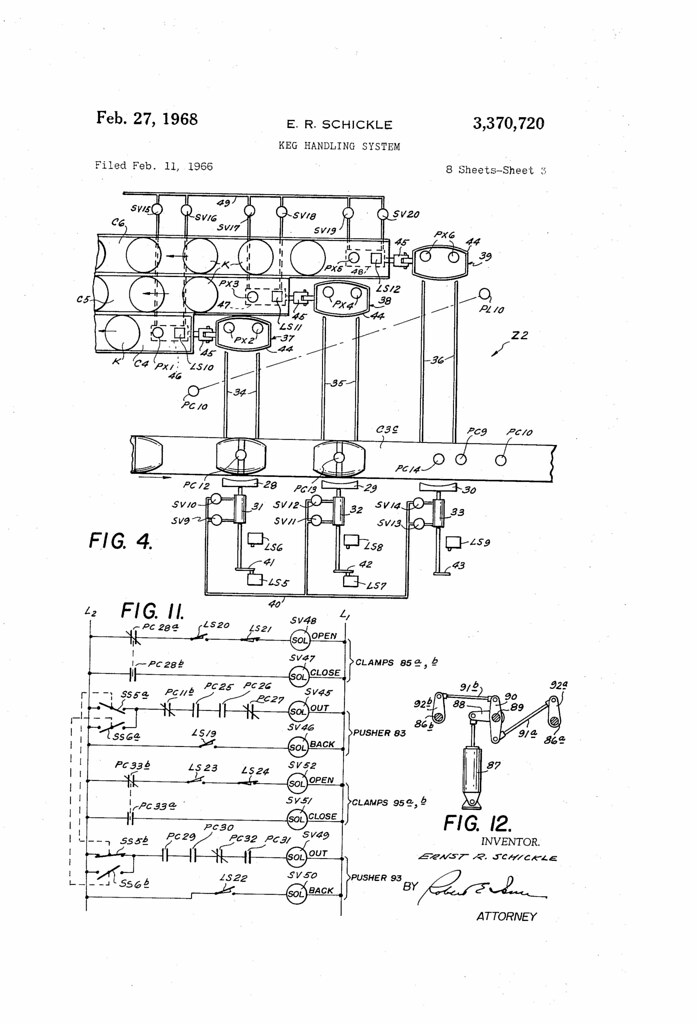

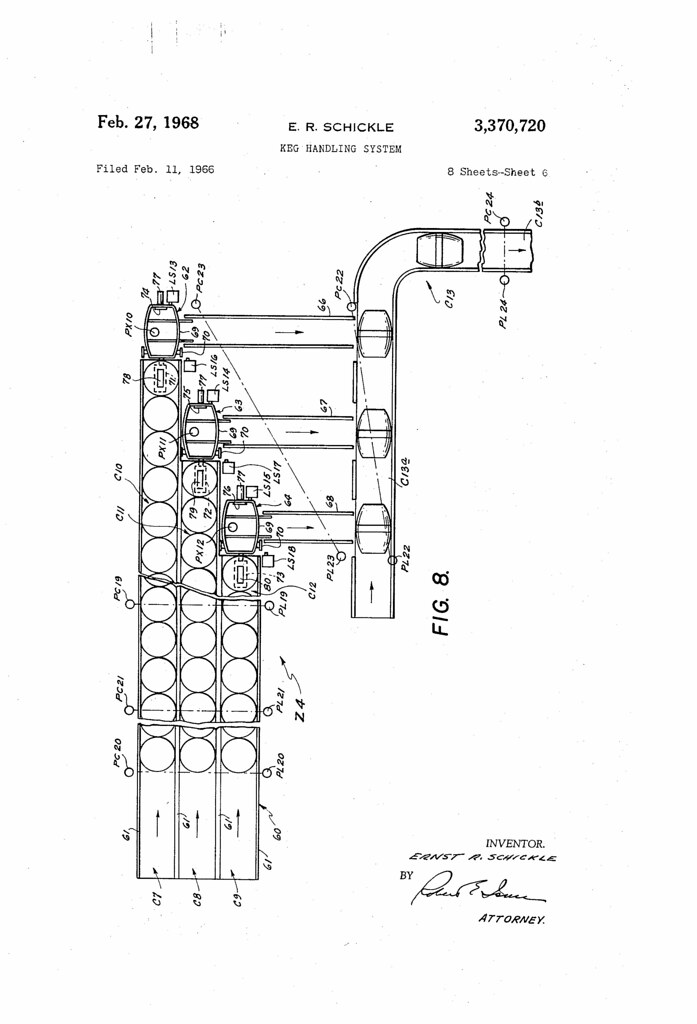

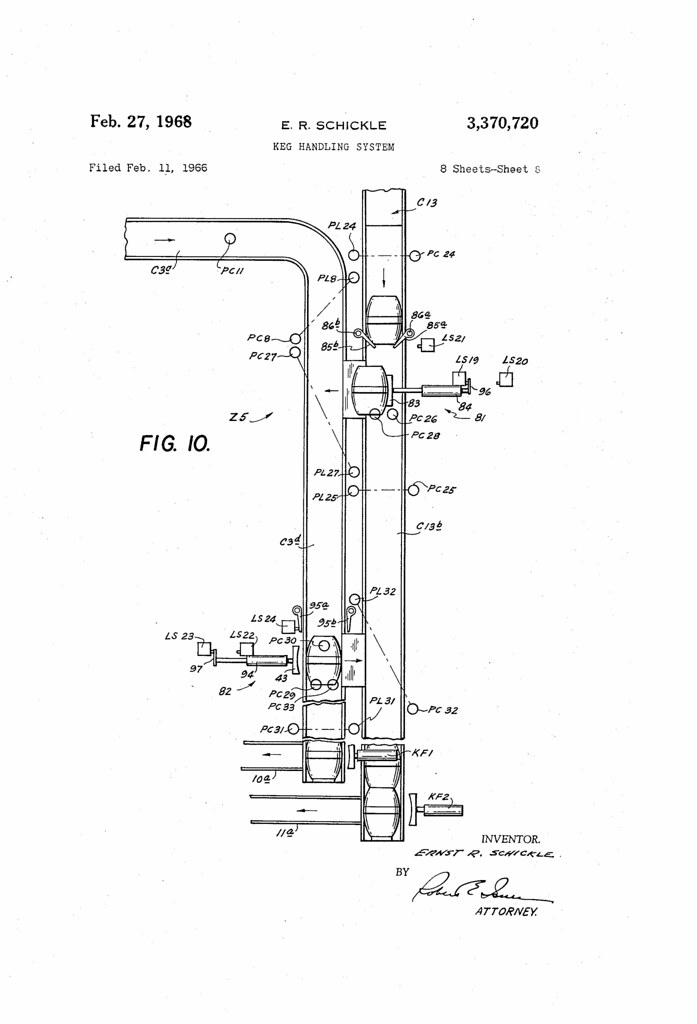

Accordingly, it is an object of this invention to provide an efficient automated system for handling empty kegs returned to the brewery, and for continuously maintaining an adequate supply of such empty kegs at the keg washing apparatus so as to permit continuity of operation of the latter at its optimum rate. Another object is to provide a keg handling system which, during the period when empty kegs in excess of the demand of the washing apparatus are returned to the brewery, accumulates those excess kegs in convenient groupings for storage and, thereafter, or whenever the demand for kegs at the washing apparatus exceeds the rate at which returned kegs are being conveyed thereto, is effective to separate individual :kegs from groupings thereof removed from storage and to convey the same in succession to the washing apparatus so as to permit continuity of operation of the latter.

A further object is to provide a keg handling system of the described character which transports or conveys the kegs in a prone position, that is, with each keg lying on its side so as to facilitate the movement and handling thereof, and which disposes each keg to be stored in an erect position, that is, standing on an end thereof, so as to require the smallest possible floor space for the storage vof the groupings of empty kegs and further to facilitate the stacking thereof, until such time as the empty kegs are required to satisfy the demand of the washing apparatus.

Still another object is to provide a keg handling system of the described character which requires a minimum of supervision of its operation, but which is nevertheless extremely flexible so as to be capable of satisfying the varying requirements and exigencies of brewery operation.