Today in 1951, US Patent 2575658 A was issued, an invention of Roger Del Nero, for his “Beer Faucet.” There’s no Abstract, although in the description it includes these claims:

Beer has always presented problems in dispensing. It contains carbon dioxide gas, which in a sealed keg is held in solution. Upon tapping of the keg, however, it is necessary to apply pressure from an external source to keep the gas dissolved within the keg, this pressure ranging, for example, from 25 to 35 pounds. It would be desirable to retain the gas in solution until the beer is dispensed from the faucet. It is here, however, that many problems arise, and these will be mentioned briefly.

For example, the faucet is of course exposed to room temperature, and yet should be chilled if a good glass of beer is to be drawn, since the relative warmth of the faucet may cause excessive foaming of the beer by release of the gas. Keeping a faucet at a single low temperature is practically impossible, because it might be inactive for a time, during a slack period of sales, and become relatively warm.

At other times, continuous drawing will keep it chilled. All this can happen during the use of a single keg. After a period of inactivity, good bartenders spit the faucet before drawing the next glass, that is, they clear the faucet of beer trapped therein that may be stale, and of escaped gases rising to the faucet through the supply lines and coils. The loss of good beer through the drain, before the faucet is again dispensing beer properly, has been considerable.

Other factors affect the drawing of beer, too, as for instance, agitation of the beer within the keg when tapping, the melting of ice in the coil box, and change of temperature in a mechanically cooled system.

From the above, it is seen that merely putting a keg under a pressure previously determined as best will not in itself result in each and every glass drawn having no more than a proper amount of foam, even though the particular bartender may be fully expert in his work. This has been the problem, and to meet it, the art has concerned itself with devising a faucet that can be adjusted by the bartender to meet varying conditions experienced from glass to glass. All such faucets as have been commercially practicable have been of a two-valve type, having a main valve operated by the usual knob lever, and a second valve separately adjustable for the purpose of restricting the passageway through the faucet in varying degree.

So far as I am aware, however, the faucets heretofore devised, and aimed at conquering the drawing. This is when it is most important to do so, because he does not note any change in the characteristics of the beer until he actually begins drawing. If he has to stop drawing, make an adjustment of the flow control valve, test the new position, and perhaps stop and make still another adjustment, valuable time is lost. 01′, if he attempts an adjustment without stopping, he must relinquish the knob lever. Usually, by the time he reaches the adjustment lever, the glass is overflowing.

Additionally, the provision of faucets of this type has brought forth an undesirable condition, in that many of them contain so many parts that they not only can get out of order easily, but what is more important, perhaps, the volume of parts, and the comparatively large size of the faucet, affects adversely proper chilling thereof, and tends to bring forth one of the very conditions intended to be overcome.

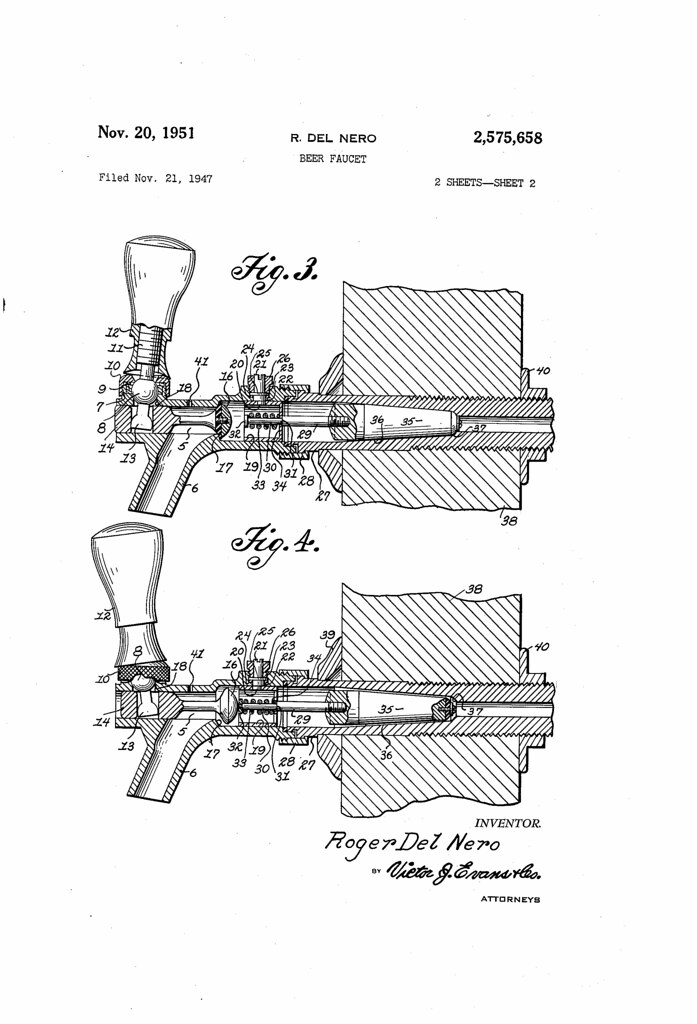

I have had in mind, then, the provision of a faucet that can be small and will have less parts than other faucets intended to accomplish the same purpose; that will permit an adjusted setting of the flow control valve, to be made on installation, taking into consideration such factors as beer temperature desired, length and size of supply lines and coils, and the pressure applied to the keg; that will additionally permit the bartender to make further adjustment of said valve during actual drawing, to meet varying abnormal and unexpected conditions not expected at the time the drawing of the glass began, such further adjustment to be made immediately and without loss of control of the knob lever; and that will permit spitting of the faucet without loss of good beer.

To this end, the presently preferred form of my invention embodies, mainly, a faucet having a main valve operated by the conventional knob lever; a flow control valve; an adjusting sleeve that effects an adjusted, normal setting of the flow control valve, usually made at installation, this means being capable of being locked; and a stem that extends from the flow control valve and is engageable by the main valve, whereby the bartender can make a further adjustment of the flow control valve during drawing by operation of the knob lever.