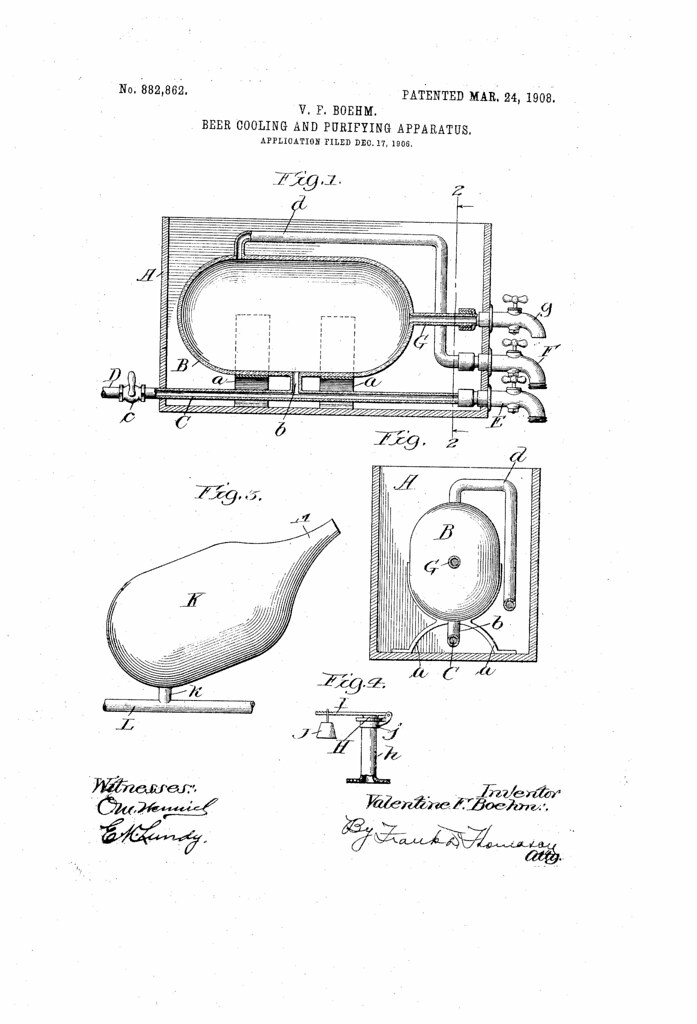

Today in 1908, US Patent 882862 A was issued, an invention of Valentine F. Boehm, for his “Beer Cooling and Purifying Apparatus.” There’s no Abstract, and in the description it probably includes a summary, but the OCR did a pretty bad job and it’s all but unreadable. Don’t say I didn’t warn you.

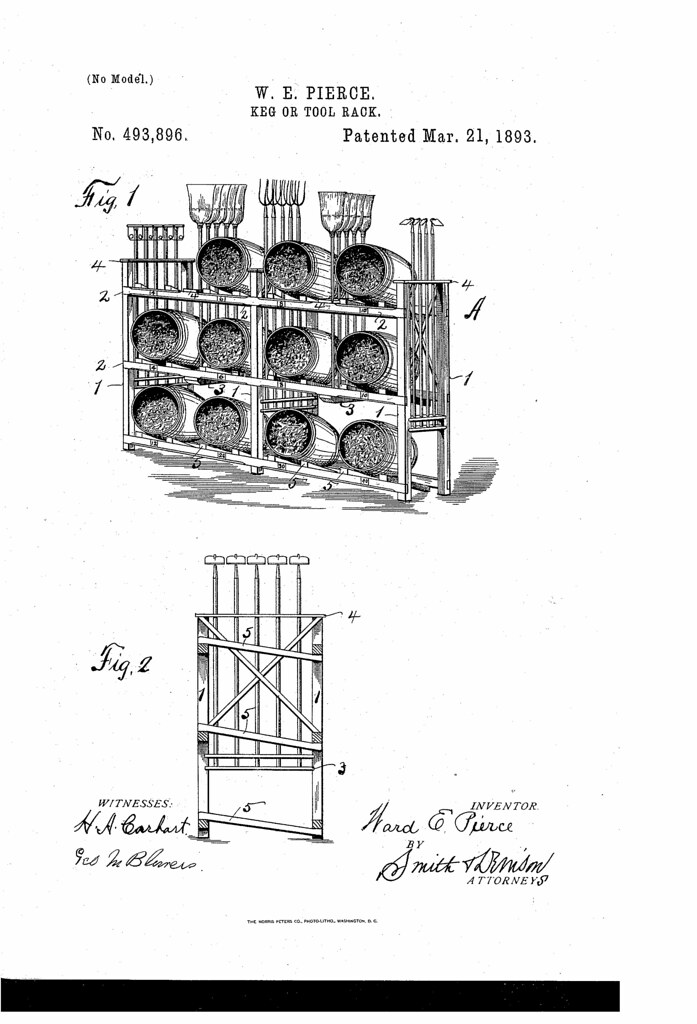

Patent No. 493896A: Keg Rack

Today in 1893, US Patent 493896 A was issued, an invention of Ward E. Pierce, for his “Keg or Tool Rack.” There’s no Abstract, although in the description it includes this summary:

My invention relates to keg or tool racks and particularly to that class which is adapted to be stored and shipped in knock-down shape, to be readily set up in stores and vending places, and which afford easy and convenient means for holding nail kegs, agricultural implements.

My object is to produce such a rack which may be readily assembled at the place where it is desired to be used, and adapted to hold kegs in a very convenient position so that the goods may be readily displayed therefrom; and also easy and convenient means for holding hoes, forks, brooms, &c.,taking up a minimum amount of space.

Patent No. 46973A: Improved Process For Obtaining A Condensed Extract Of Hops

Today in 1865, US Patent 46973 A was issued, an invention of Samuel R. Percy and Walter S. Wells, for his “Improved Process for Obtaining a Condensed Extract of Hops.” There’s no Abstract, although in the description it includes this summary:

Our invention consists in the preparation of a condensed extract of hops, which possesses all the valuable properties of the hops, which is computed to lose about thirty-three and one-third per cent of their strength the first year, and afterward to decline more rapidly. All these and other objections are entirely obviated by our invention.

A quantity of hops is placed in an air-tight vessel, and the air is then exhausted therefrom in any of the methods ordinarily used for that purpose. Warm or cold water is then introduced, which should be kept heated by the admission of steam, and the hops allowed to steep for two or three hours. The degree of heat is not essential. We prefer that it should approach nearly to the boiling-point of water in vacuo. A small quantity of alkali or alkaline salts should be added to the water, the amount, when so used, not to exceed one pound of alkali or its equivalent of alkaline salts to I every one hundred pounds of hops. When the hops, by these means, are sufficiently digested, a vacuum is formed in a chamber communicating with the vessel in which the hops have been steeped, so that when the cooks communicating between this vessel and this receiver are opened the water and condensed steam containing the virtues of the hops pass through into the receiver, a vacuum being maintained therein sufficient to draw all the liquid from the hops. Water and steam are again and again admitted into the steeping vessel, as before described, until the hops are entirely exhausted of their properties. The fluid thus holding said properties in suspension is strained through a suitable strainer adjusted within the connecting pipe while in transition from the steeping-vessel to the receiver. When a sufficient quantity of this fluid extract of the hops, effected as above stated, is accumulated in the receiver, a vacuum evaporating-pan is ready for its reception by covering or coating its inner surface with any oily or fatty substance cerine, paraffine, &c., to prevent the extract from adhering to the pan and burning. Avaouum is then formed in this pan and the fluid extract is drawn through a pipe or tube connecting with the receiver, as fast as needed, into this vacuum, evaporating, or condensing pan. At such time, during the process of evaporating and condensing such fluid, as the operator may deem proper, a quantity of molasses, saccharine matters, or the extracted liquor of grain, whether malted or not, is to be drawn into the vacuum condenser and mixed with the fluid therein contained, amounting in quantity to about three gallons of molasses orits equivalent proportion of saccharine matter or extracted liquor of grain to every one hundred pounds of hops employed,though these proportions are by no means arbitrary. The whole is then evaporated or condensed to the consistence of very thick molasses, after which it may be taken out and put into vessels for use or transportation.

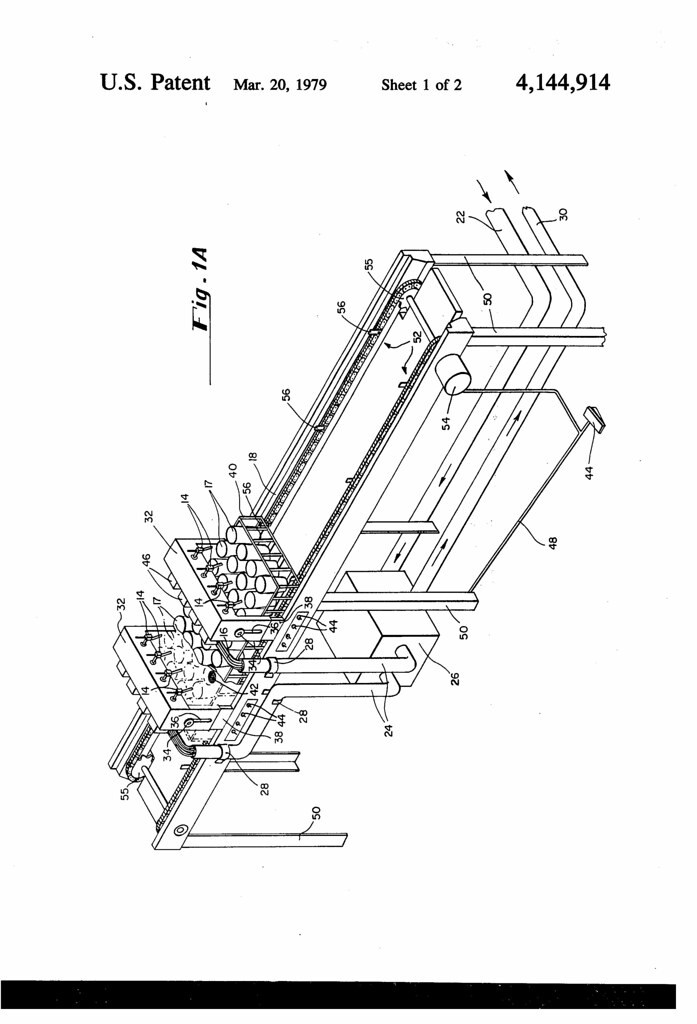

Patent No. 4144914A: Apparatus For Rapidly Dispensing Beer Into Open Cups

Today in 1979, US Patent 4144914 A was issued, an invention of John W. Nilon and Thomas J. King, for their “Apparatus for Rapidly Dispensing Beer into Open Cups.” Here’s the Abstract:

Beer is stored in vessels located in a refrigerated storage area before passing through dispensing lines connected to a plurality of dispensing taps. The dispensing lines are maintained in heat-exchanging relationship with cooling apparatus which further depresses the temperature of the beer below that of the refrigerated storage area. By the time the beer reaches the cooling taps, the temperature of the beer is sufficiently depressed so as to permit the beer to be dispensed at a high rate into drinking containers which pass beneath the taps.

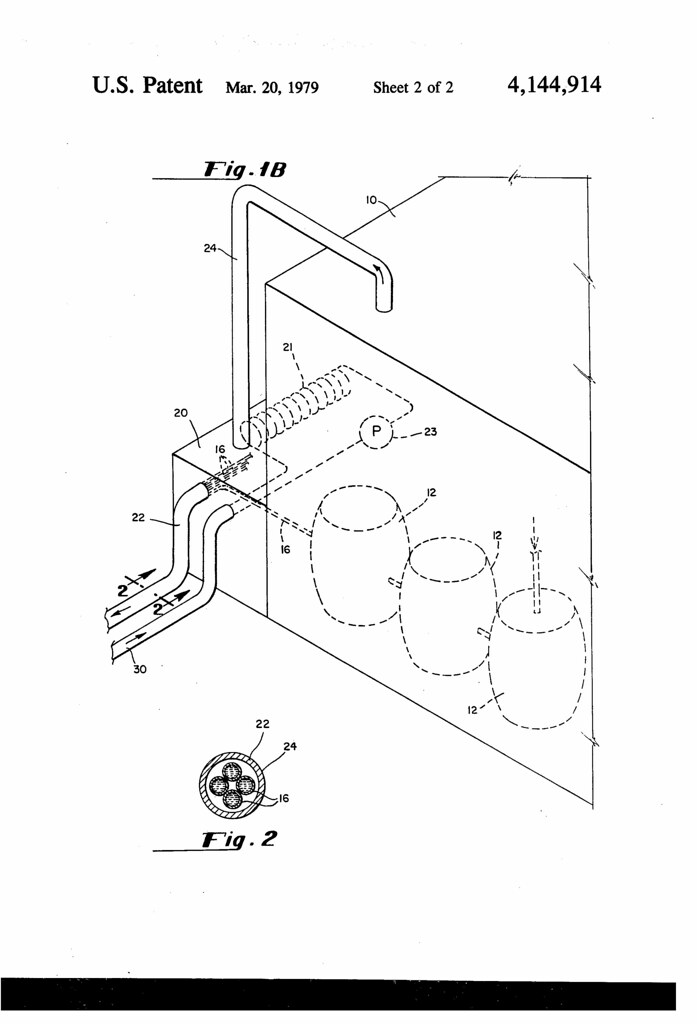

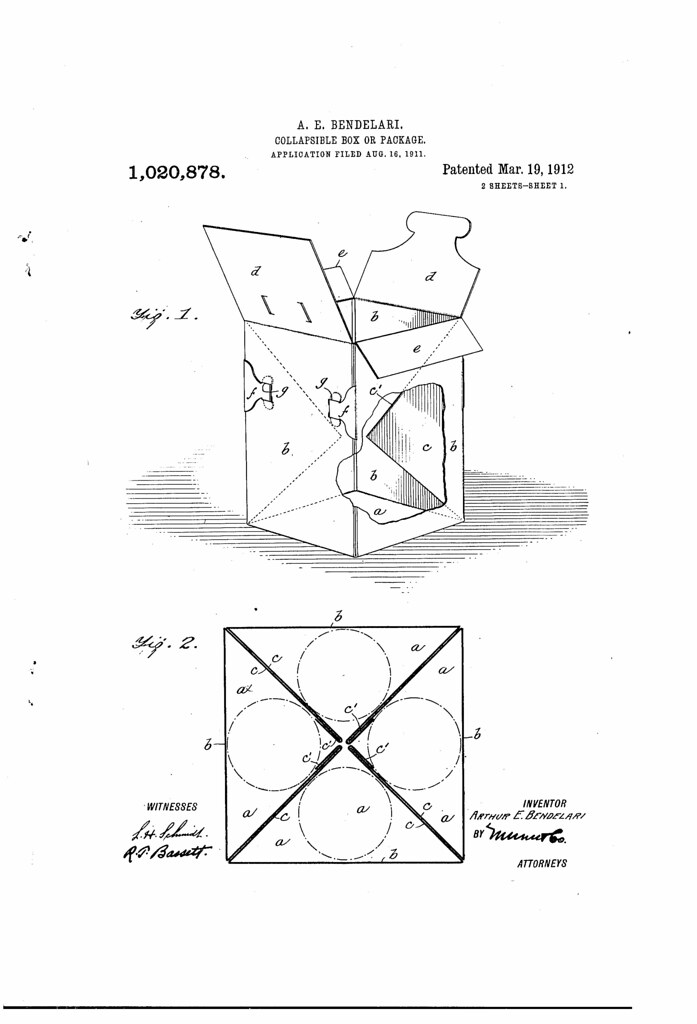

Patent No. D210566S: Keg Cradle

Today in 1968, US Patent D210566 S was issued, an invention of Frederic C. Jay, for his “Keg Cradle.” There’s no Abstract, and in the description there isn’t much beyond the self-evident claim that it’s a keg cradle.

FIG. 1 is a perspective view of the keg cradle embodying my new design, the keg being indicated in broken lines for illustrative purposes only.

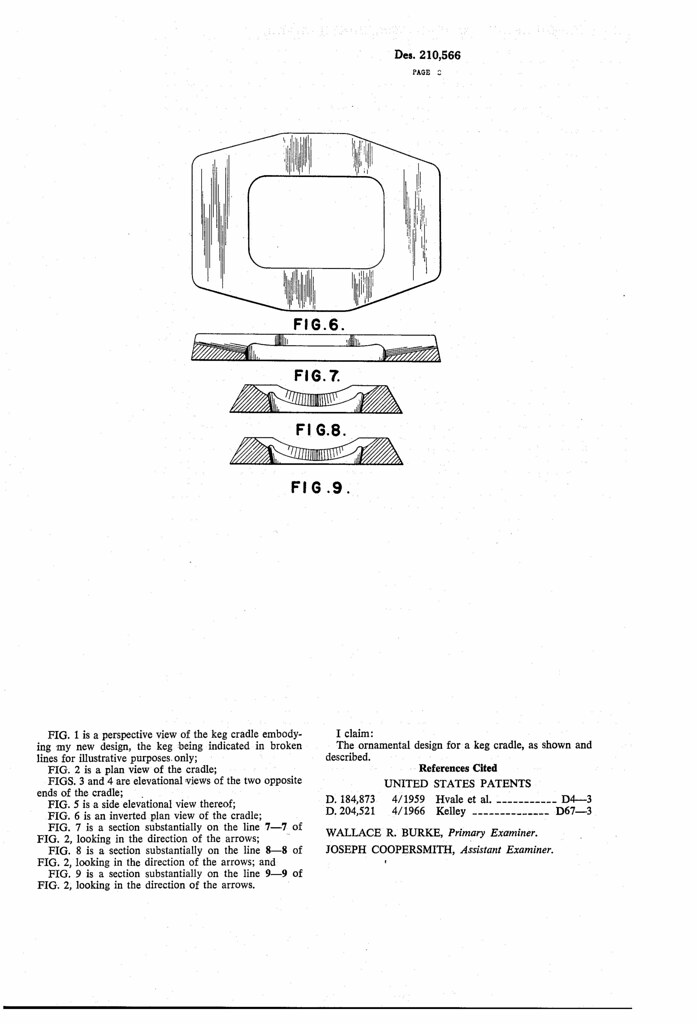

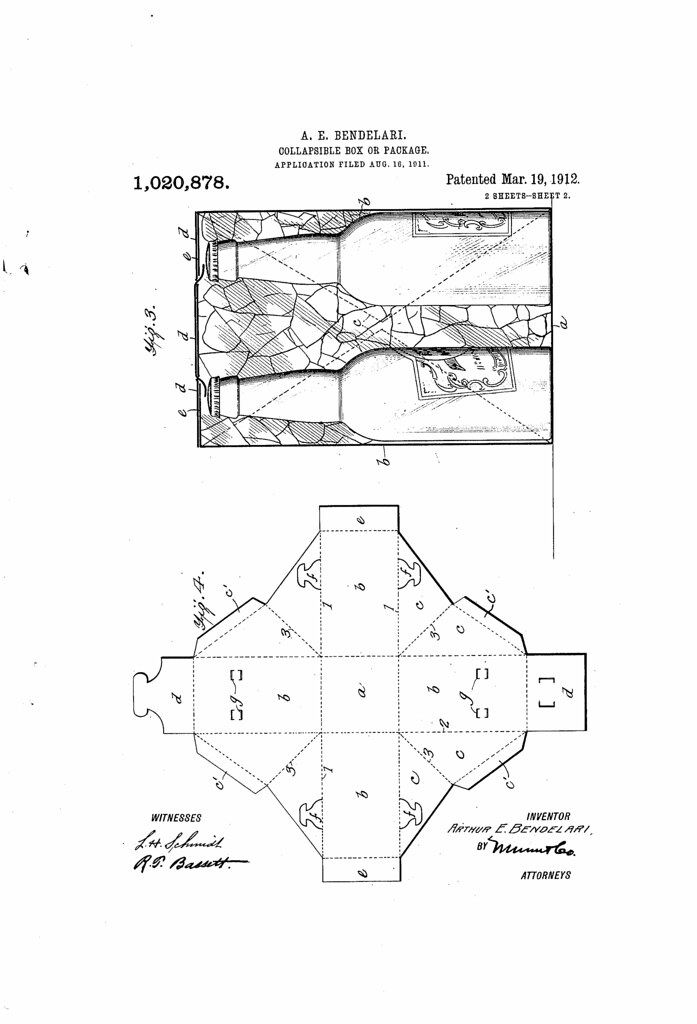

Patent No. 1020878A: Collapsible Box Or Package

Today in 1912, US Patent 1020878 A was issued, an invention of Arthur E. Bendelari, for his “Collapsible Box or Package.” There’s no Abstract, although in the description it includes this summary:

The object of my invention is to provide an improved collapsible rectangular box or package which shall be particularly adapted for holding and shipping beer-bottles, but may be used for other analogous purposes. The box is made from a single sheet of paraffined cardboard, the same being adapted to fold in such manner as to provide interior projecting portions that serve as vertical, diagonal partitions that meet at the center of the box chamber and divide the chamber, or interior of the box, into four equal compartments, each of which is adapted to contain a bottle.

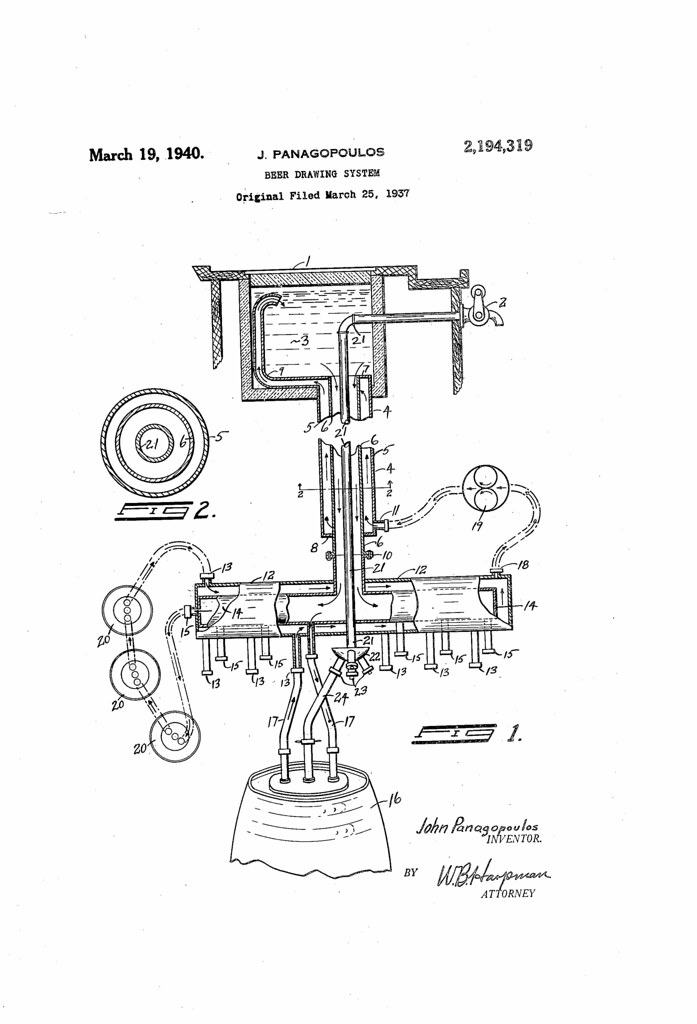

Patent No. 2194319A: Beer Drawing System

Today in 1940, US Patent 2194319 A was issued, an invention of John Panagopoulos, for his “Beer Drawing System.” There’s no Abstract, although in the description it includes this summary:

Among the objects of the invention are to provide an installation of the above type in which the brew from the kegs is dispensed at a remote spigot usually on the floor above the keg, the brew being cooled and maintained not only within the kegs but also through its course of flow to the remote faucet at the bar.

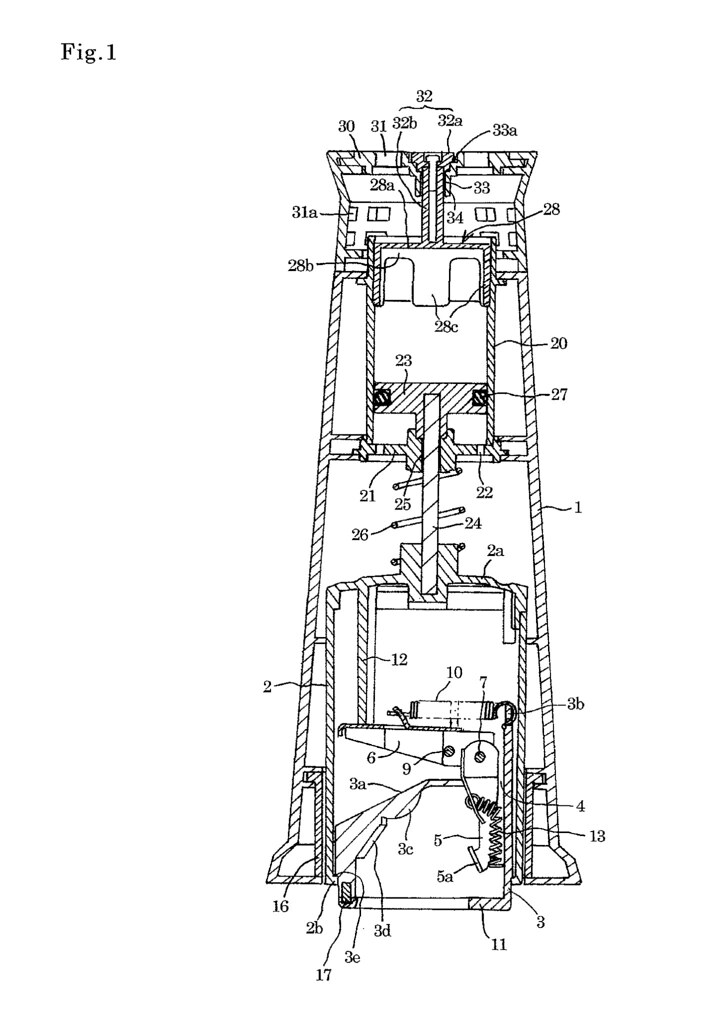

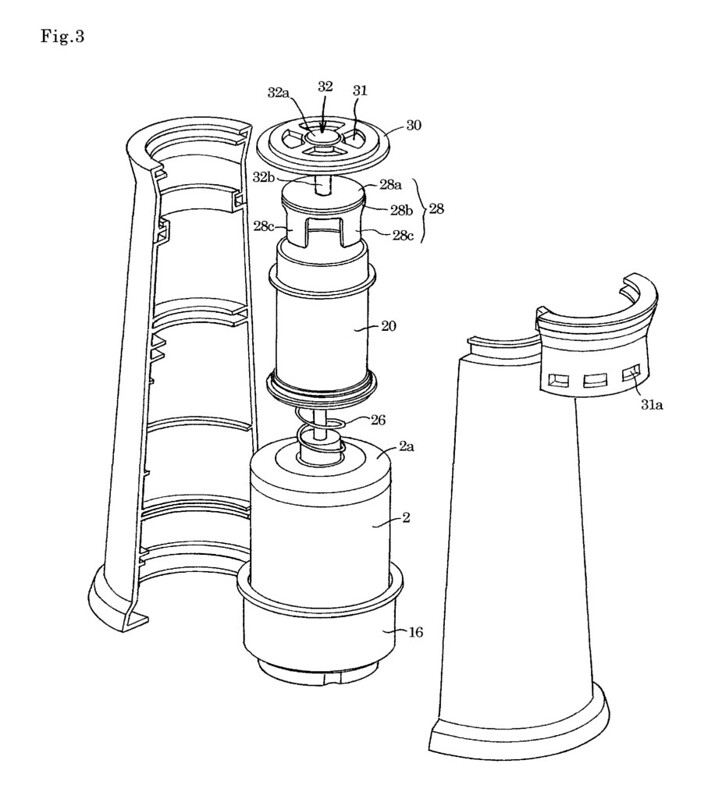

Patent No. 8671802B2: Bottle Cap Opener

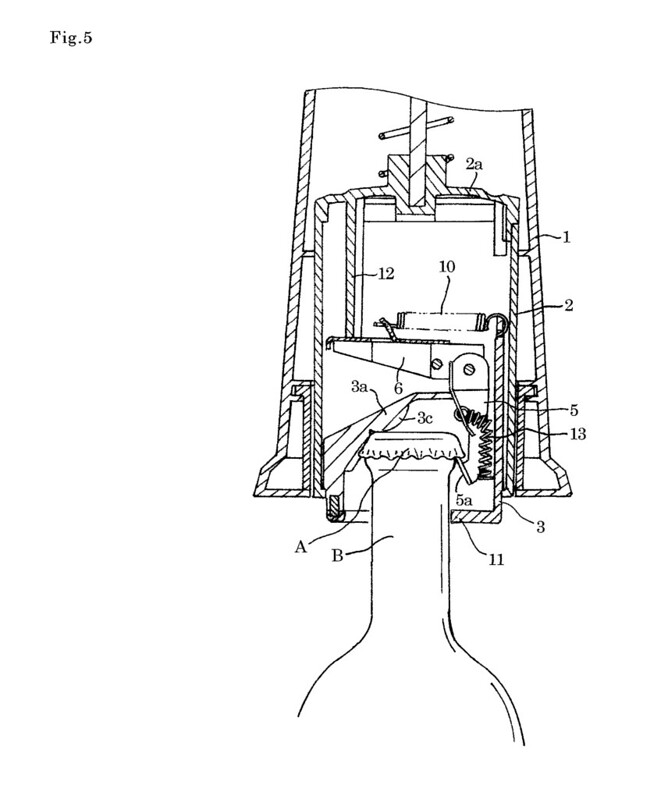

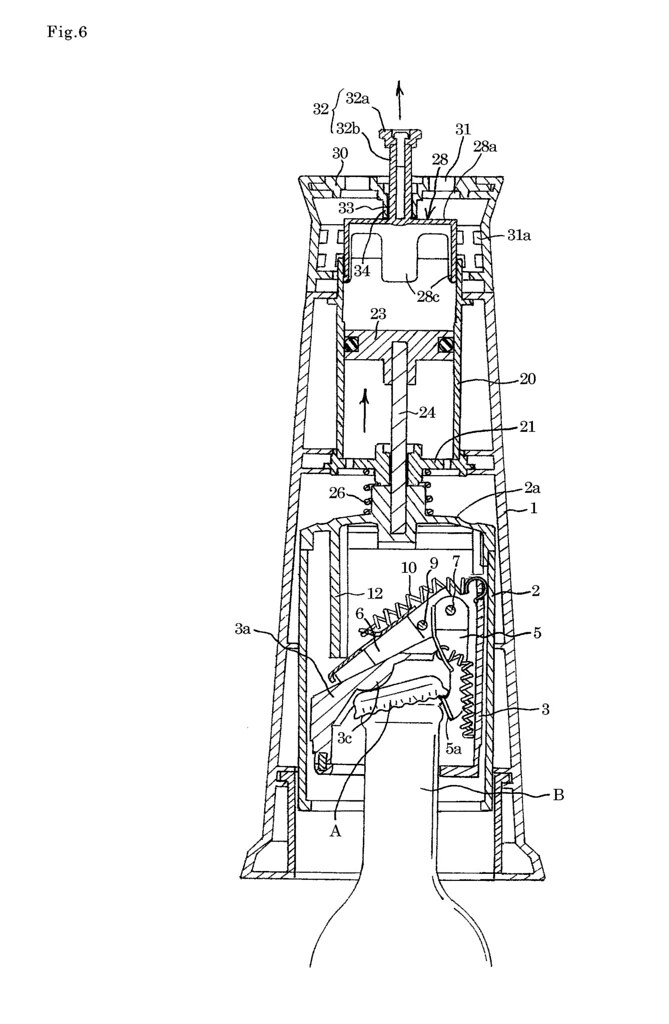

Today in 2014, US Patent 8671802 B2 was issued, an invention of Chikamitsu Takagi, for his “Bottle Cap Opener.” Here’s the Abstract:

A movable outer cylindrical member and a movable inner cylindrical member are arranged vertically movably in a lower half of a cylindrical main body. By placing the movable inner cylindrical member on a bottle mouth and pushing down the cylindrical main body, a lower end of a hooking member is engaged with a lower end of the crown cap to pry the crown cap away. At the same time, the movable outer cylindrical member is moved up and a piston inside a cylinder arranged in an upper half of the cylindrical main body is moved up with the movable outer cylindrical member, so that the air in the cylinder is compressed, and a cover member is brought out in by the compressed air.

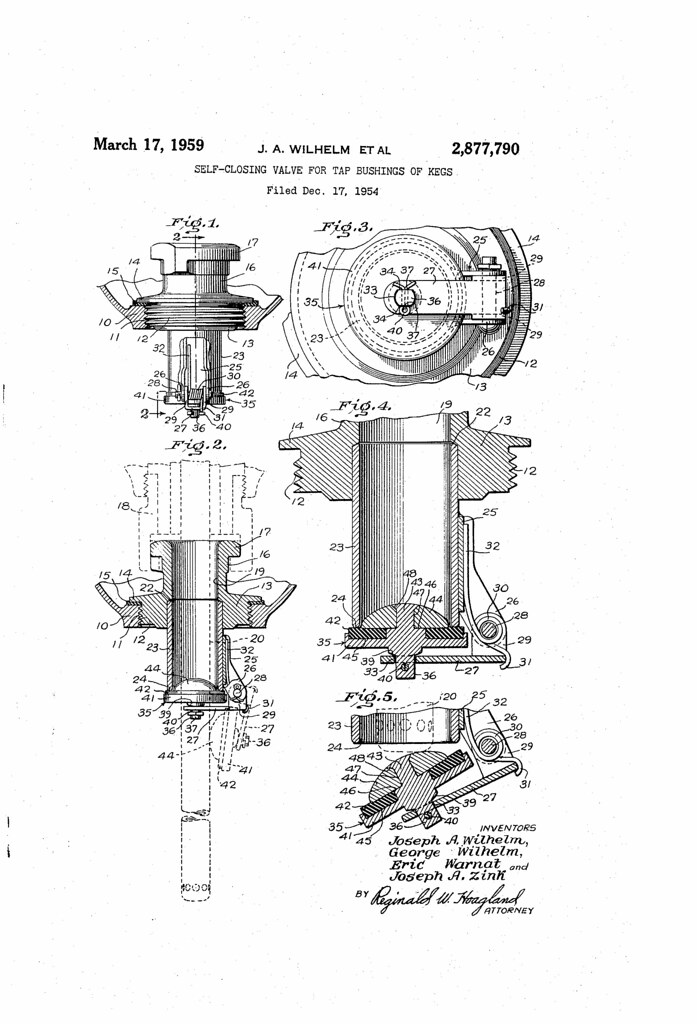

Patent No. 2877790A: Self-Closing Valve For Tap Bushings Of Kegs

Today in 1959, US Patent 2877790 A was issued, an invention of Emil Clemens Horst, for his “Self-Closing Valve for Tap Bushings of Kegs.” There’s no Abstract, although in the description it includes this summary:

The present invention relates to self-closing valves, and more particularly to valves used with tap bushings of beverage kegs for sealing off the interior of the kegs except during such time that said kegs are on tap for dispensing the contents therefrom.

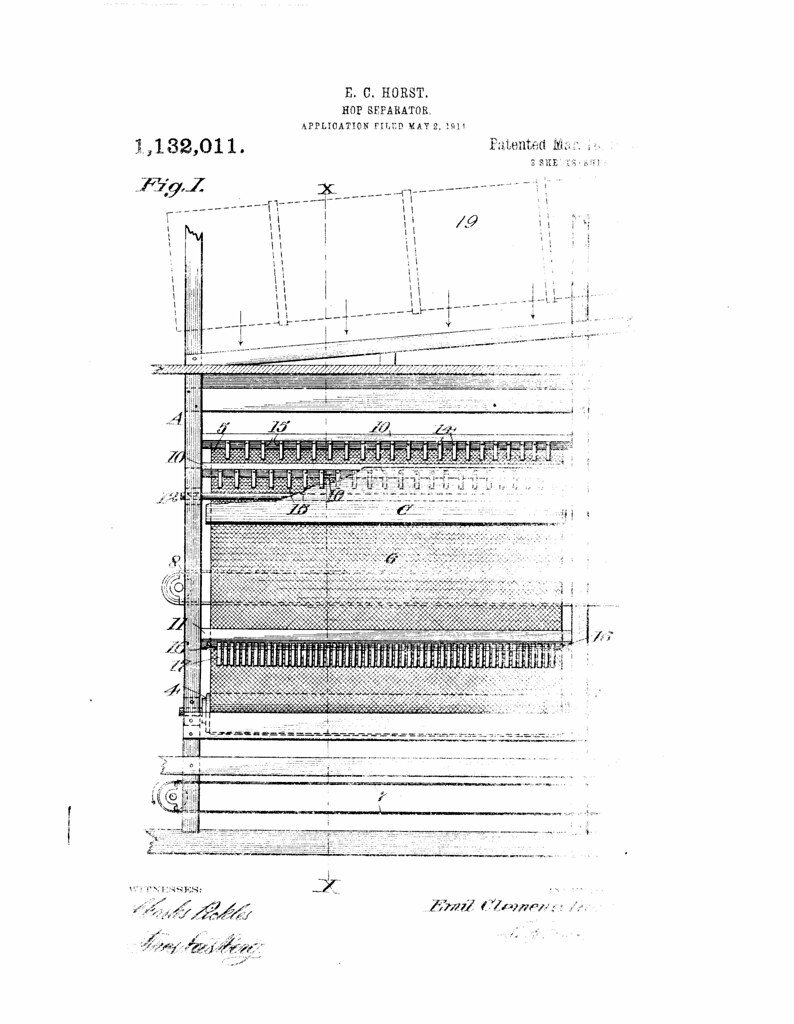

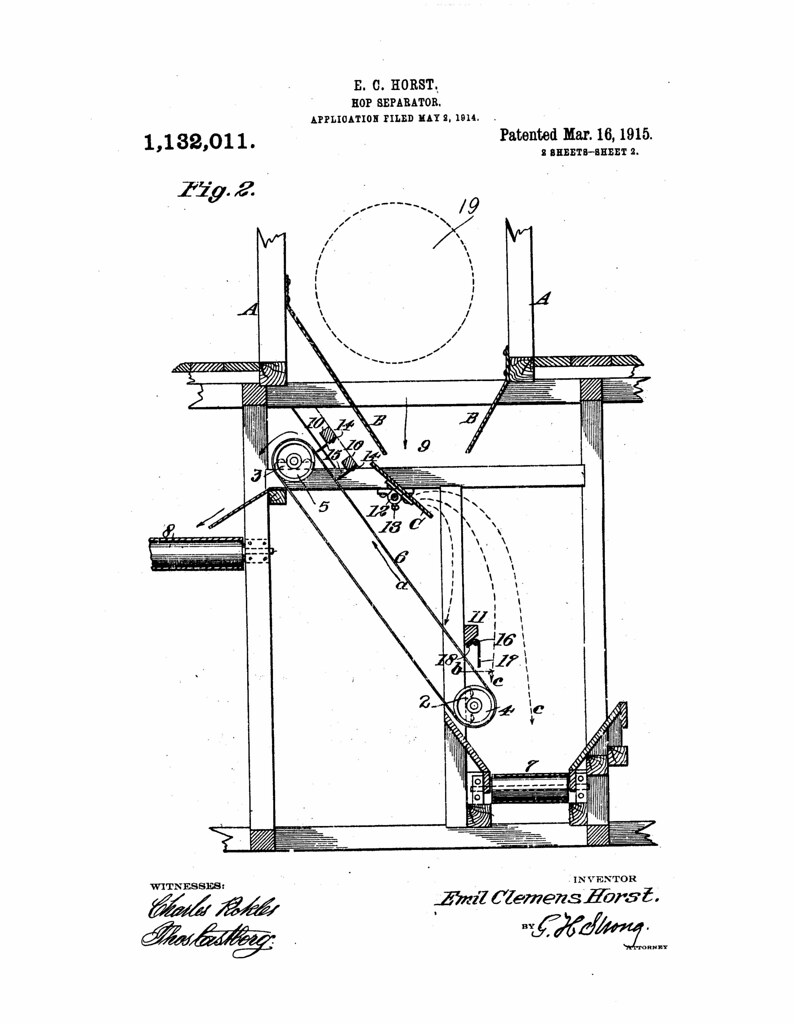

Patent No. 1132011A: Hop Separator

Today in 1915, US Patent 1132011 A was issued, an invention of Emil Clemens Horst, for his “Hop Separator.” There’s no Abstract, although in the description it includes this summary:

This invention relates to hop separators employing upwardly traveling endless separating belts; and the objects of the invention-are first, to provide a simple, substantial, easily regulated apparatus in which the hops may be quickly separated from the leaves and trash with which they are commingled after being stripped from the vines; second, to provide an adjustable deflecting plate between the separator and the source of supply by which a portion of the hops may be deflected out of reach of the separating apparatus, and third, a plurality of tackle is operable in connection with the separator to prevent any hops from passing through the separator with the leaves.