Today in 1942, US Patent 2281457 A was issued, an invention of Sven Olof Rosenqvist, for his “Aeration of Fermenting Wort in the Manufacture of Yeast.” There’s no Abstract, although in the description it includes this summary:

In the manufacture of pressed yeast it is known to blow air into the worts to increase the yeast yields; As a rule the fermentations are now performed with the use of the running-in method, the level of the wort in the vat being considerably lower at the commencement than at the termination of the fermentation. As a rule, it is desired during the start and at the termination of the process to supply less air to the wort than during the main portion of the fermentation. During the main portion of the fermentation it may also be of interest sometimes to be able to supply air quantities of different magnitudes.

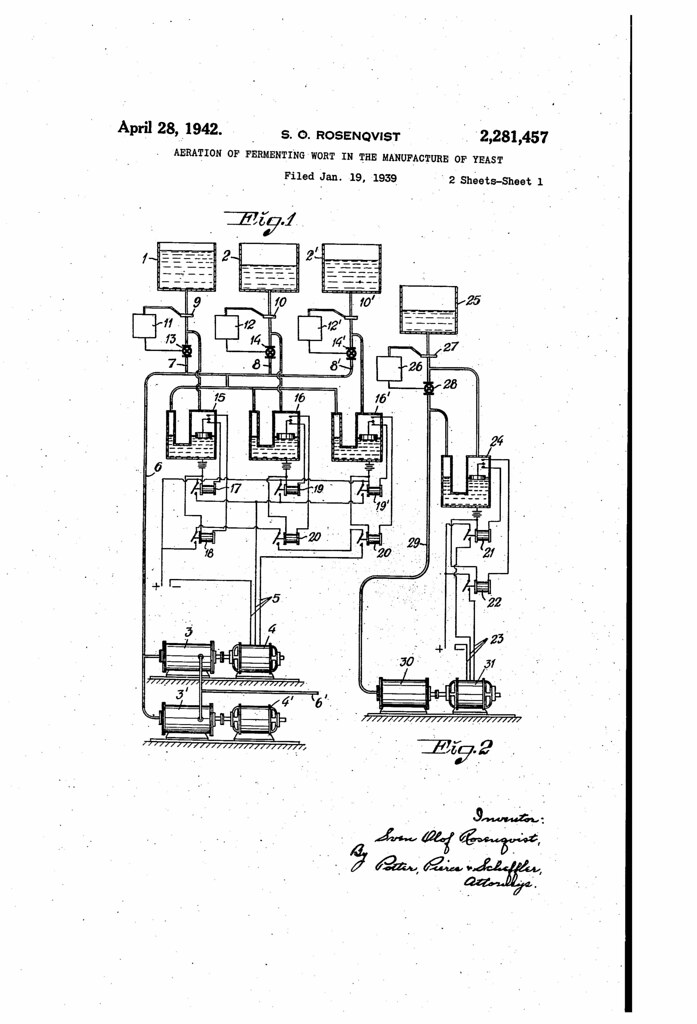

Generally, one or more compressors of the same or of different types would operate on a ‘common pressure conduit branched off to the various vats’. By employing large compressor units, the air of which would be distributed to a plurality of vats, a rather low installation cost would be obtained for the compressor system. At the same time, however, the disadvantage would be incurred that the pressure on the air piping always would have to be maintained at a value corresponding to the highest back pressure prevailing in any vat.

Air taken out from the pipe system for a vat with a lower back pressure thus would have to be reduced by a valve from the higher to the lower pressure, which obviously would involve losses of energy.

With large compressor units, the losses in idle running would also be considerable at a low load.

Any control of the air quantity for the various fermentation vats could only take place manually with the arrangements described and with loss of energy. A control of the air quantity to a fermentation vat from the common conduit would entail disturbances in the air supply to the remaining vats and in order to limit such disturbances the pressure above atmospheric in the main conduit would have to be maintained at. an unnecessary high value. The arrangements as hitherto used consequently could not, owing to the fact that the control would be less accurate or too expensive, ensure the proper air supply to each of the fermentation processes proceeding in the various fermentation vats at an energy cost as low as possible. By reason of the fact that the supply of the quantities of air undertaken at the fermentations could not be properly adapted with respect to the process otherwise carried out in connection with these fermentations, the lowest cost for the aeration work, the best yield of the raw materials and the best quality of the finished product consequently could not be obtained.

The present invention refers to an arrangement for the supply of air to fermenting wort in the manufacture of pressed yeast, in the use ‘of which the above described disadvantages are avoided.

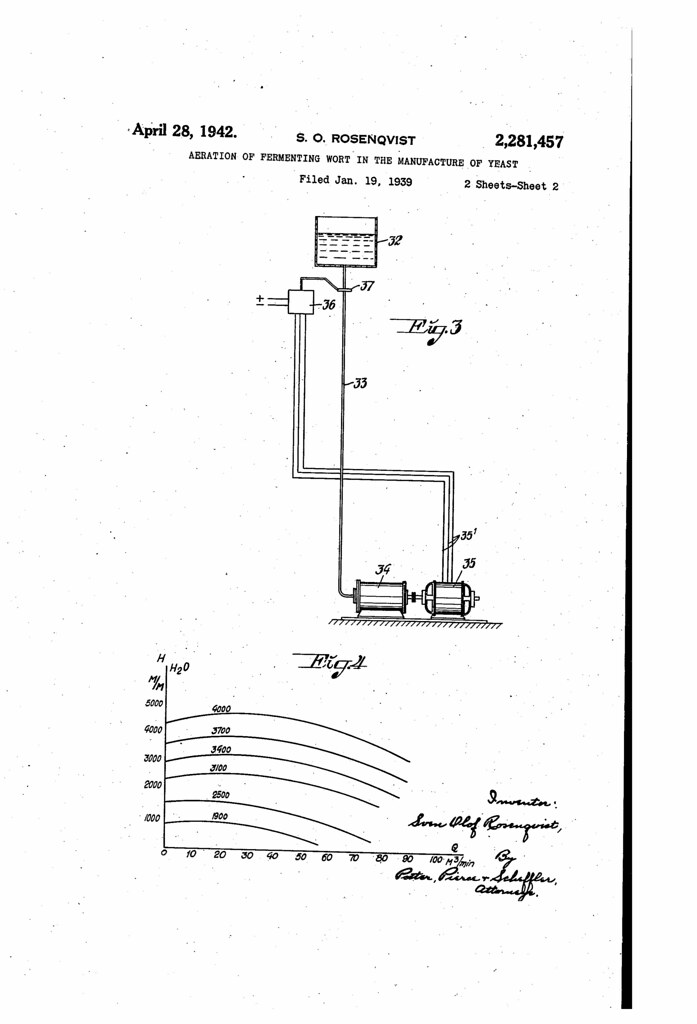

The arrangement according to the invention is principally distinguished by a compressor apparatus adapted to be controlled with respect to the delivery of air, the pressure conduit of which apparatus is connected to the plant of fermentation vats, and by an arrangement with a continuously driven member adapted to control the intensity of aeration in accordance with a previously determined aeration scheme, and which may actuate the air delivery of the compressor apparatus by influencing the compressor apparatus itself, its suction or pressure conduit or its driving machinery, or two or more of these arrangements, and which is so arranged as to adjust the compressor apparatus automatically and in accordance with an aeration scheme determined beforehand, to deliver air in a quantity and at a pressure required by the scheme at any moment. Preferably, a measuring device is provided to indicate the amount of air passing on its way to the fermentation vat, said measuring device being adapted to give impulses to the controlling doling device. According to an embodiment of the invention, the controlling doling device is adapted directly or indirectly to actuate a device, in ,order, in the case of double acting compressors, to convey a portion of the air to that part of the compressor which operates at a pressure below atmospheric. According to a further embodiment, a measuring device for the air in the inlet or outlet of the compressor “is arranged to transmit impulses for the control of the number of revolutions of the driving engine of the compressor.

Also. a measuring device for the air may be arranged to effect throttling in the inlet or outlet of the compressor so as to control the quantity of air in this way. If a compressor be used. a turbo-compressor adapted to be controlled with respect to the number of revolutions thereof is preferably made use of.