Today in 1938, US Patent 2127759 A was issued, an invention of John F. Silhavy, for his “Method of and Apparatus for Producing Wort and the Like.” There’s no Abstract, although in the description it includes this summary:

This invention relates to a method of and apparatus for the production or wort or similar liquid mixtures.

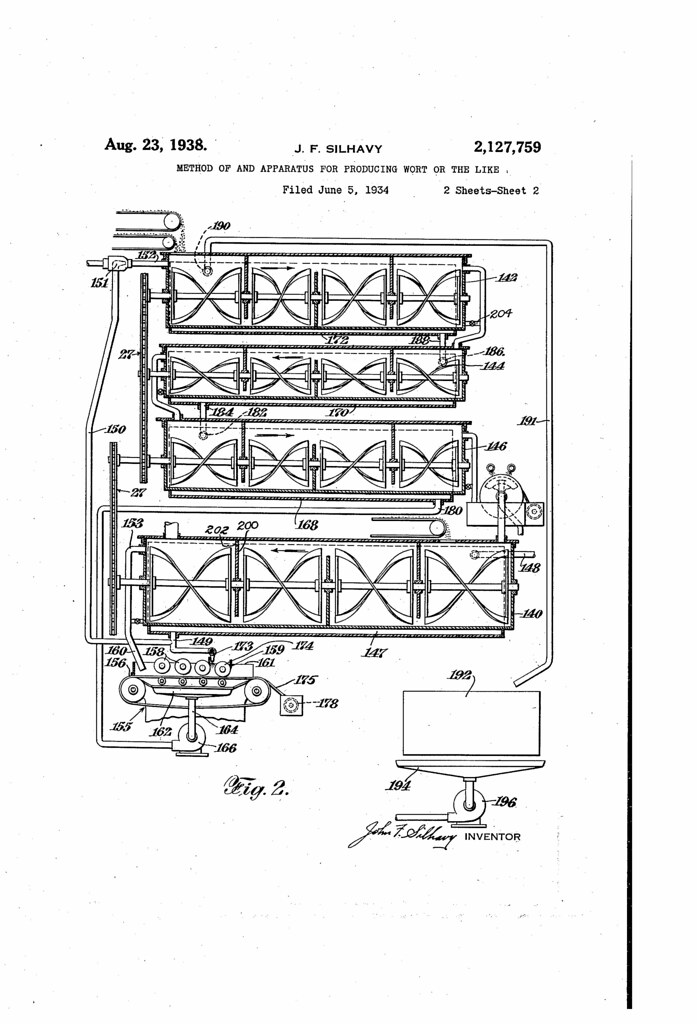

The object of my invention is to overcome the objections and defects of the batch processes now in use. I have invented a continuous process for, the production of cooled wort. My invention includes the steps of mixing the necessary cereals with water at the proper temperature while continuously progressing the mixture through a mixing section, then mixing and heating at a higher temperature in another section while advancing the material continuously, and then heating it to a higher temperature and moving it along continuously in another section. After this mashing treatment the cereals are continuously removed by filtration with a suction filter or similar device. The cereals on-the suction cylinder are sparged with hot water to wash out desirable water soluble constituents. The liquid (filtrate) is then conducted to a ‘section where hops are added. The mixture is stirred or agitated and advanced through a heated section. This agitating may be obtained merely by a vigorous boiling. The mixture with the hops is pre-cooled and then filtered by passing it over a continuous suction filter or the like and the hops on the suction roll sprayed or sparged. In another form of my invention, I filter the hops from the liquid without pre=cooling and pass this hot liquid through the jackets of the mash mixers or mixing sections to heat the liquid in the mixers. The liquid is then passed through a final cooler and from here the wort is run into the fermenters. As each fermenter is filled, yeast may be added. In the more detailed description hereinafter given, I will describe the various steps and also improvements of the steps.

Instead of using separate mixing sections or mash mixers, in some instances I prefer to combine the first two mash mixers in one unit. Or I may combine the last two mash mixers in one unit or I may combine all three mash mixers in one large unit and still maintain the desired temperatures in the sections within allowable limits. I have found that by adding carbon dioxide gas or carbonic acid gas to the mash, the diastatic action of the malt as well as the peptonization of the albuminoids is increased.

By using my continuous process there is a saving of time because it is not necessary to wait for large bodies of liquid to be heated. Also there is ease of control due to processing a relatively small quantity of’material continuously rather than a much larger quantity in the batch manner. The method is flexible to meet the requirements of individual operators. The resulting wort is more uniform on account of the continuity of the process. There is also a larger output per unit of floor space since all apparatus is in continuous use in contrast to present practice, where the greater part of the equipment is idle and only a small portion of the equipment is in operation at one time. Due to the improved mixing and to the more thorough washing or sparging of the spent cereals and grains, a better yield from a given weight of cereals is obtained. A large economy is effected by utilizing the boiled wort as a heating medium in the earlier stages of the process. This is made possible by the continuity-of the process. Since my continuous process requires only a relatively small amount of water for washing out adhering wort from the grains on the filter, it is possible to work with a much thinner mixture in the mash mixers than is done at present in the mash tun. By using a more liquid or thinner mixture a much better extraction yield on the grains is obtained. Also with a thinner mash, the rate of diastatic activity is higher than I with a thicker mash. A more uniform product at a lower cost is obtained as a result of using my invention. One feature of my invention is the continuity of the process. Another feature of my invention is the arrangement of the apparatus. Still another feature of my invention is the continuous filter means provided. Still another feature is the economizing in heat which is provided for by the arrangement of the apparatus. Other features and objects will be in part obvious and are in part above pointed out and will be pointed out hereinafter. Various changes may be made in practice within the scope of my invention without digressing from the spirit of my invention.