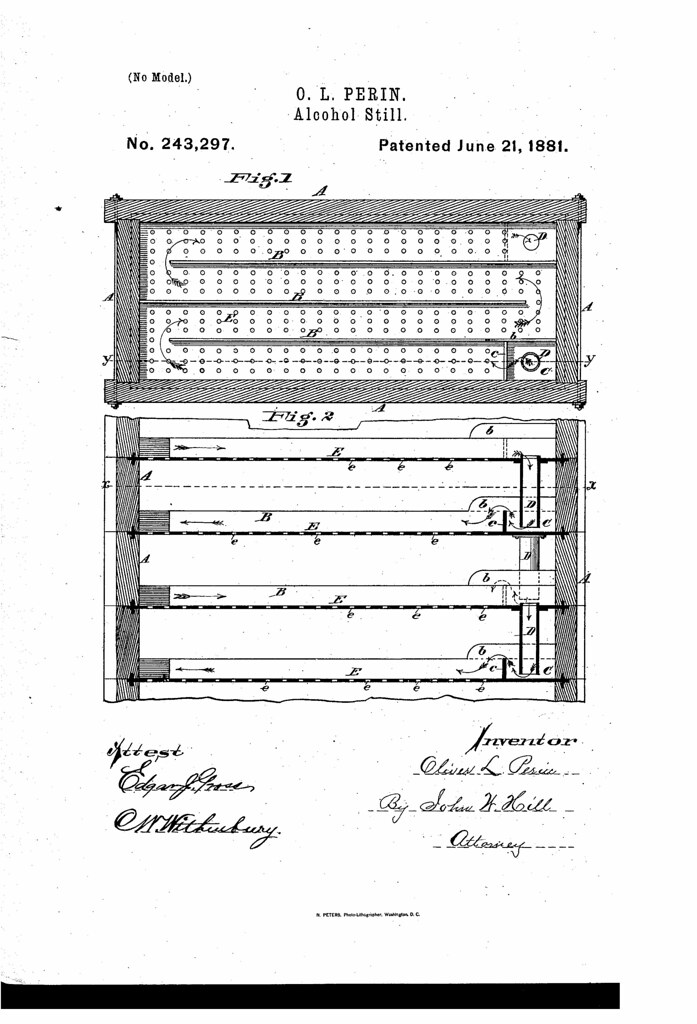

Today in 1881, US Patent 243297 A was issued, an invention of Oliver L. Perin, for his “Alcohol Still.” There’s no Abstract, though it’s described this way in the application:

My invention is in the nature of an improvement upon a continuous still for the manufacture of alcohol for which Letters Patent were granted myself, Daniel Horan, and Dominick McGoen, July 20, 1880, and has for its object the arrangement of the several elements of the vaporizing-chambers in a novel manner, to be hereinafter described, which is calculated to improve the efficiency of the still, and at the same time will materially cheapen the construction thereof; and it consists in constructing the vaporizing-chamber of the usual rectangular form, and providing a bottom or licor of copper or other suitable material, which shall contain a great number of small perforations. Upon this bottom I erect three (or any odd number more than three) partitions, alternately attached to the opposite end timbers of the chamber. The partitions are made as much shorter than the clear length of the chamber as the width of spaces between the partitions and side timbers of the chamber and between adjacent partitions. At the end of one of the spaces between a partition and its corresponding side timber of the chamber I construct a box or bay with a weir or overflow plate of copper, raised two or three inches above the floor or bottom of the chamber. The partition at the bay is raised higher than the edge of the weir, in order that all beer or mash delivered into the bay shall be compelled to pass over the weir in a thin sheet, and be evenly distributed over the bottom of the chamber as it flows along the next connecting channel. From the next chamber above a down-pipe is’ suspended, which dips into the bay below the level of the Weir-plate sufficiently to form a seal against the steam-pressure in the chamber and prevent the steam ascending to the next chamber above through At the opposite side of the chamber a down-pipe is suspended to dip into the bay of the next lower chamber. The upper end of the down-pipe is raised sufficiently above the floor or bottom of the chamber to which it is attached to maintain a thin sheet ot’ liquid over the perforations in the bottom previously mentioned. The beer or mash flows through the down-pipe into the bay, over the weirplate and down one channel. formed by the partitions previously mentioned, and up the next, and down the next, and so on until it reaches the down-pipe at the opposite side of the chamber, through which it descends to the next chamber below, where the same operation is repeated, the direction of the currents of beer, however, being reversed. Meanwhile the beer or mash, passes over the floor, the steam (introduced first into the lowest chamber but one of the still) and the spirituous vapor ascends from chamber to chamber through the perforations in the bottoms of the chambers, these perforations being of such dimensions that no beer or mash can descend through them against the pressure (usually five or six pounds) in the still. The heat in the steam being transmitted to the beer to expel the spirit, it condenses and works back through the down-pipes to the bottom of the still, where it is drawn oft with the residuals of the beer as slop.