Today in 1959, US Patent 2892472 A was issued, an invention of Rudolph H. Breeback, assigned to Crown Cork & Seal Co., for his “Filling System.” There’s no Abstract, although in the description it includes this summary:

Although the system of the present invention is described hereinafter as relating to the delivery of beer from Government tanks to filling machines in a brewery, it is within the scope of the present invention that other carbonated liquids, such as soft drinks, or the like, could be used with this system.

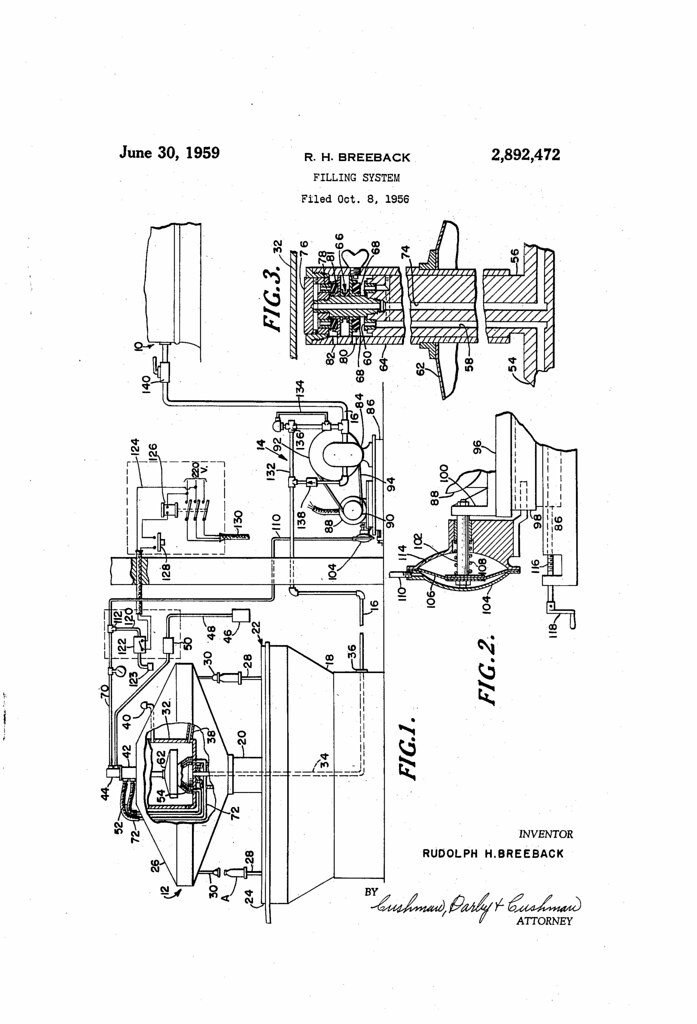

The system of the present invention basically requires a storage tank for the carbonated liquid and a filling machine with a reservoir therein for receiving the carbonated liquid from the storage tank for delivery to containers. The Government tanks used in breweries for brewing and aging beer are normally used as storage tanks for the filling machines, the beer in the Government tanks being transferred directly to the reservoir of the filling machines from which the beer is then flowed into containers. It is of course within the scope of the present invention that any tank which is used to supply the reservoir of a filling machine would be considered a storage tank, within the meaning of the appended claims.

Beer and other carbonated liquids must be handled gently throughout the filling operation, including the transfer from the storage tank to the filling machine. The entrained gases in a carbonated liquid have a’tendency to escape when the liquid is unnecessarily agitated. The foaming resulting from release of gases from the carbonated liquid causes inaccurate filling of containers, as well as loss of flavor of the beverage. Heretofore, beer has been transferred from the Government tank to the reservoir of the filling machine by utilizing differential pressure between the beer in the Government tank and the gas superposing the beer in the reservoir or by pumping beer into the reservoir dependent upon the level of beer in the reservoir. Such prior systems have required that the flow of beer between the Government tank and the reservoir of the filling machine be free due to carbonation, foaming results when beer is flowed. into the reservoir.

An object of the present invention is the provision of a filling system and method whereby beer is continuously flowed from a storage tank into the reservoir of a filling machine while containers are actually being filled, thereby eliminating surges and churning of the beer being flowed.

Another object of the present invention is the provision of a filling system and method wherein the beer is continuously flowed from a storage tank into the reservoir of the filling machine While the filling machine is in operation and filling containers, the flow of beer into the filling machine being stopped only when there is a substantial break in the feed of containers to the filling machine.

Still another object of the present invention is the provision of a filling system and method wherein the beer flow into a filling machine from a storage tank is continuous when the filling machine is filling containers, the continuous flow being varied in rate flow dependent upon level changes of the beer in the reservoir of the filling machine. By increasing the flow of beer .to the reservoir when the level of beer therein is low and by decreasing the flow of beer into the reservoir when the level of beer therein is high, a continuous flow of beer can be maintained while containers are being filled during the course of a working day and stopping and starting 0 the flow is substantially eliminated.

A still further object of the present invention is to provide a system and method of supplying beer from a storage tank to a filling machine and then to a container, the influx of beer from the filling machines to the container varying the level of beer in the filling machine reservoir, the level of beer in the filling machine reservoir continuously controlling the rate of flow of beer from the storage tank thereto.