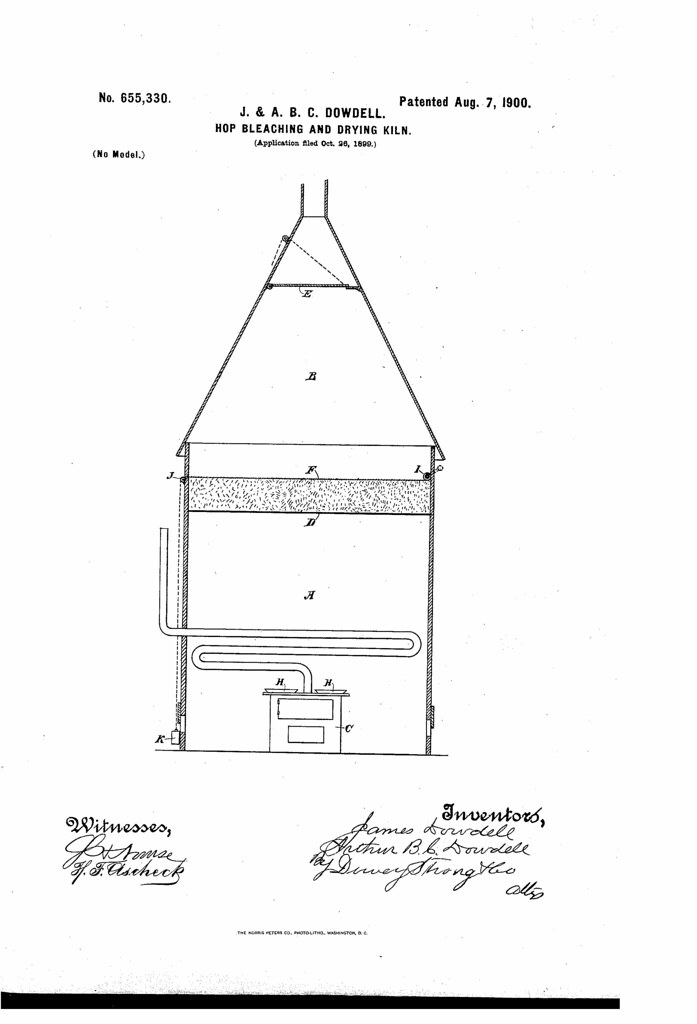

Today in 1900, US Patent 655330 A was issued, an invention of James Dowdell and Arthur B.C. Dowdell, for their “Hop Bleaching and Drying Kiln.” There’s no Abstract, although in the description it includes these claims:

Our invention relates to a means for bleaching and drying hops or other material.

It consists, essentially, of a room or compartment having a foraminous floor adapted to support the hops to be dried and in conjunction therewith a covering which may be drawn over the surface of the hops to confine and prevent heat and moisture from escaping therefrom during the process of bleaching. The sulfur fumes produced in any usual or suitable manner are caused to rise into the hops and are there retained until the bleaching is perfected, after which the covering may be removed, and heat being applied the drying will be completed.