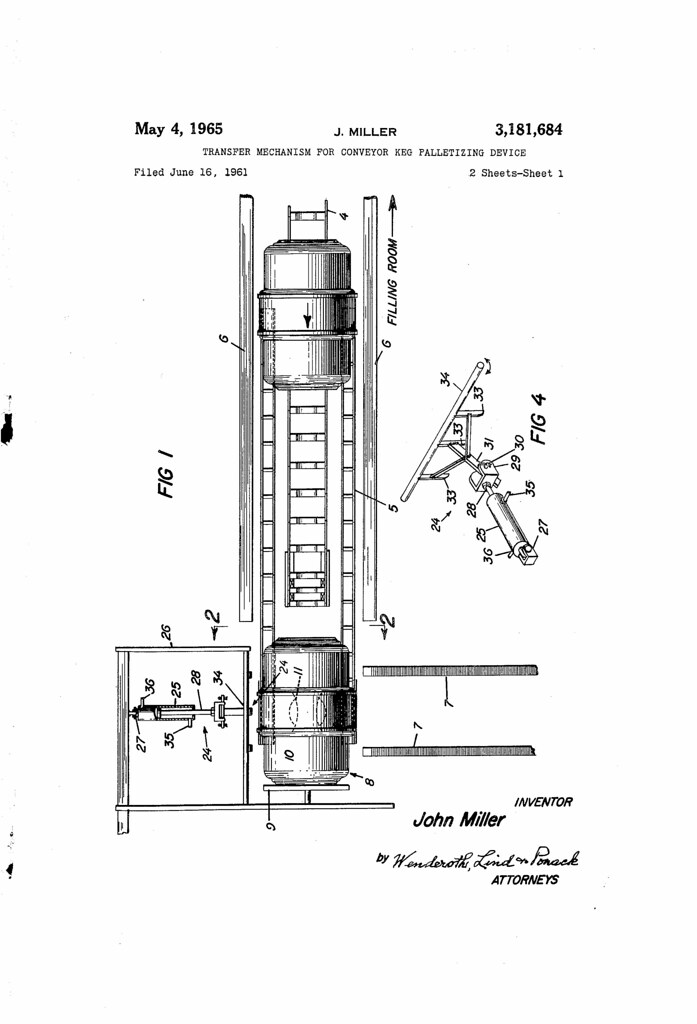

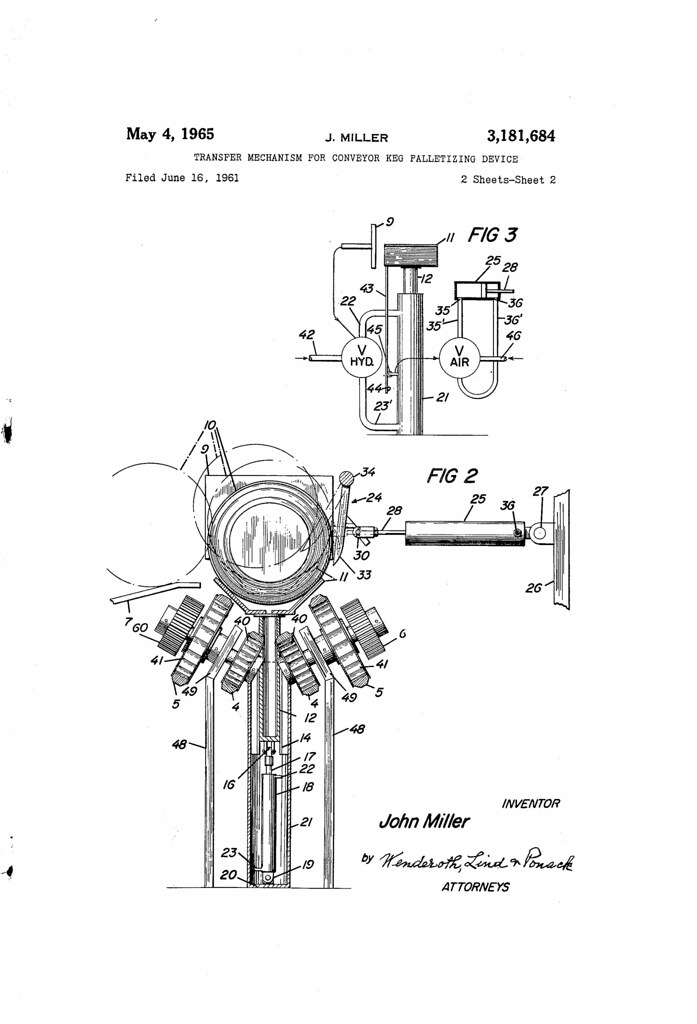

Today in 1965, US Patent 3181684 A was issued, an invention of John Miller, assigned to Schaefer Brewing Co., for his “Transfer Mechanism For Conveyor Keg Palletizing Device.” There’s no Abstract, but in the description it states that his “invention is to provide a more efficient transfer mechanism for the barrels or kegs and particularly such a transfer mechanism which is more reliable and sure in operation in transferring the barrels or kegs from the conveyor to the skids which convey such barrels or kegs to the palletizing position.”

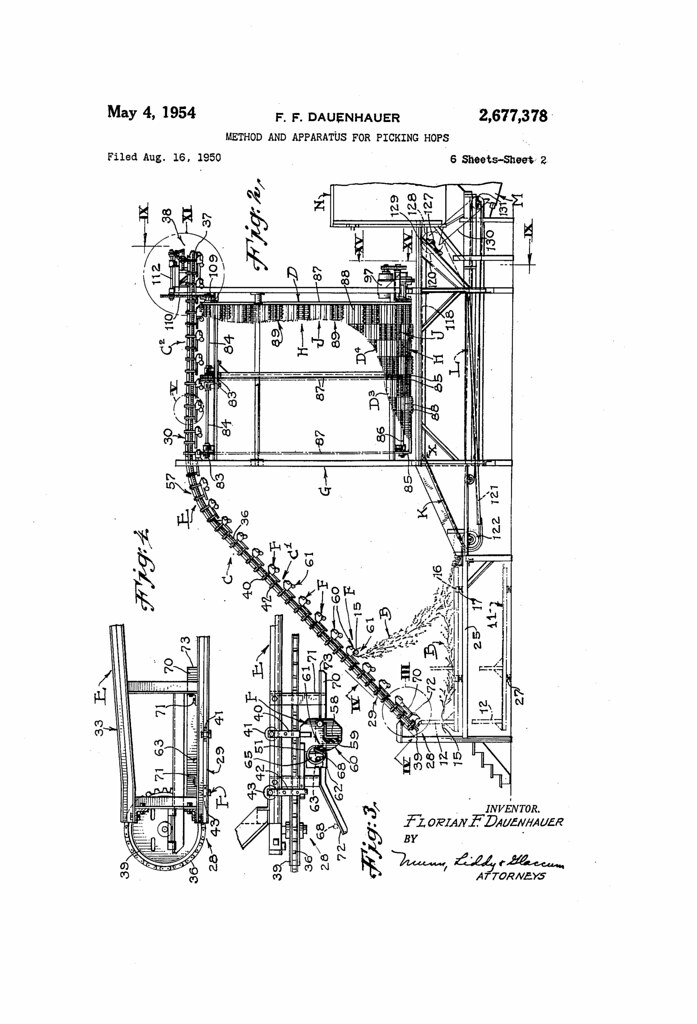

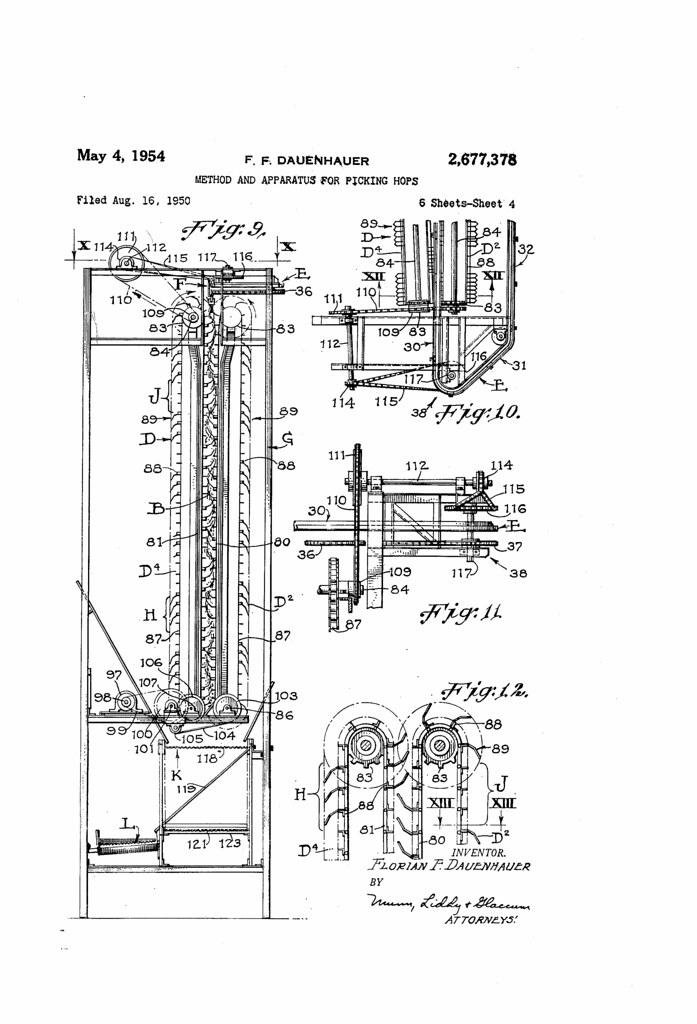

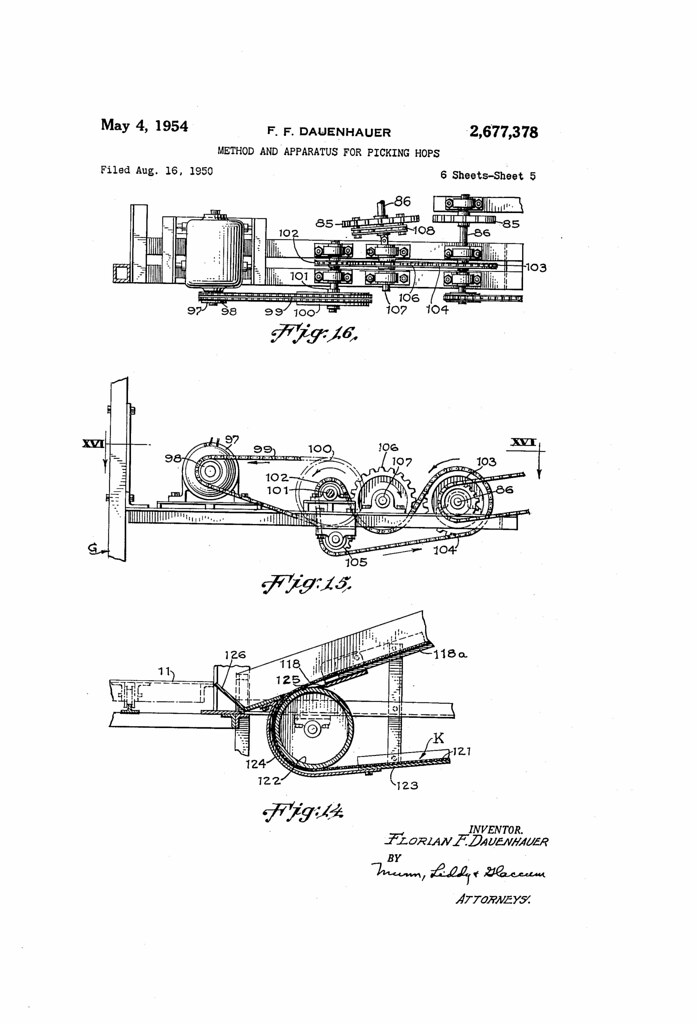

Patent No. 2677378A: Method And Apparatus For Picking Hops

Today in 1954, US Patent 2677378 A was issued, an invention of Florian F. Dauenhauer, for his “Method and Apparatus for Picking Hops.” There’s no Abstract, but in the description it states that his “present invention relates to improvements in a method and apparatus for picking hops.”

An object of this invention is to provide an improved method of picking hops from vines, assuring a thorough removal of the hops, with out damaging the hops. More specifically stated, the vines are formed into wave-like configurations, defining alternate crests and valleys extending lengthwise of the vines.

The waves thus formed are advanced lengthwise of the vines to continually replace crests by valleys and vice versa, thereby undulating the vines in first one direction and then the other for causing pendulum-like movements and exposure of the hops by the continual weaving of the vines. The hops are removed during the undulating of the vines.

Moreover, the method employs the progressive increasing of the amplitudes of the waves as the hops are picked. Also, crests and valleys of the waves are interchanged abruptly as the picking of the hops continue, and the branches of the vines are spread out laterally to expose hops and preclude the vines from matting.

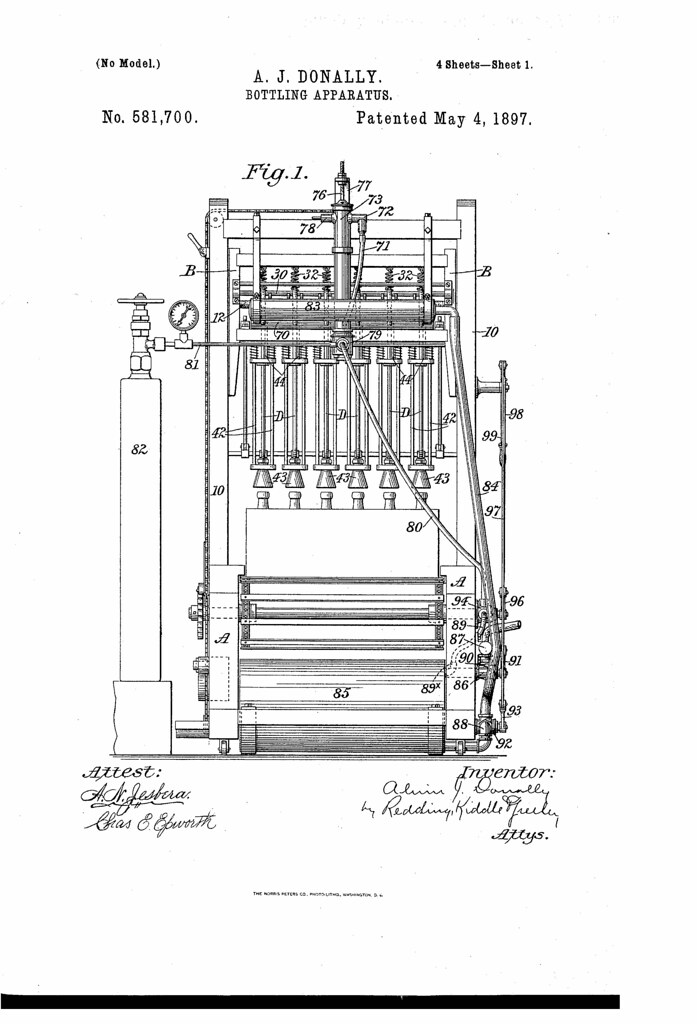

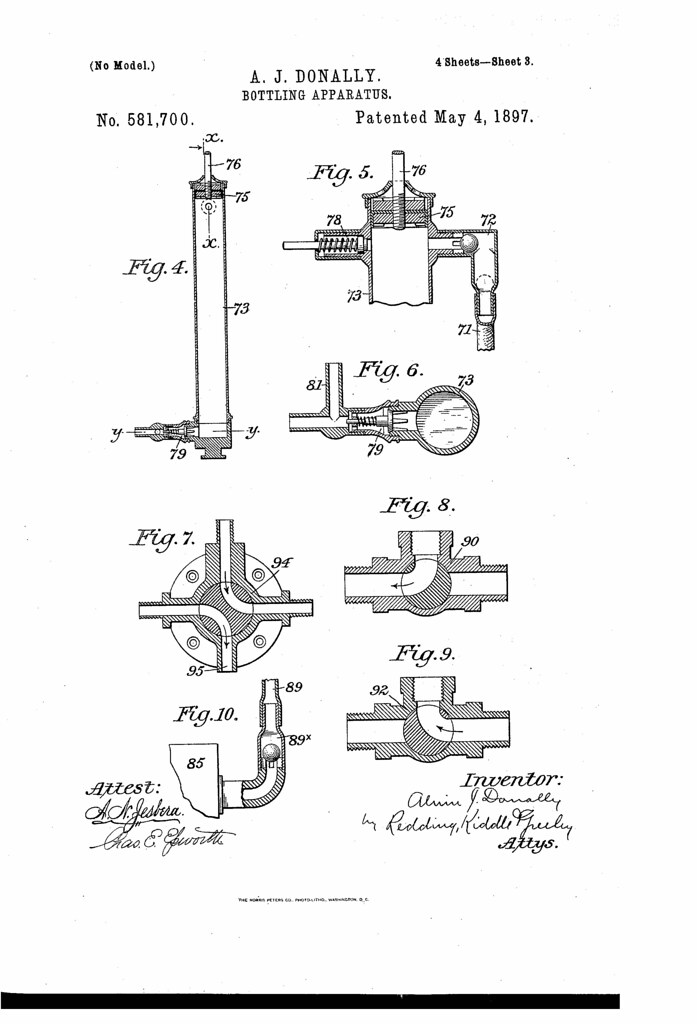

Patent No. 581700A: Bottling Apparatus

Today in 1897, US Patent 581700 A was issued, an invention of Alvin James Donally, for his “Bottling Apparatus.” There’s no Abstract, but in the description it states that he’s “invented certain new and useful Improvements in Bottling Apparatus.” While he never summarizes what those are in a short, concise sentence, he does offer this.

It is highly desirable in the bottling of various liquids, and more especially in the bottling of ale and beer, to maintain gas or air pressure on the liquid both for the purpose of retaining the gas of the liquid in solution and for the purpose of effecting the delivery of the liquid into the bottles under a steady pressure, so that there may not be any material variation in the rate of flow, and it is also desirable to keep the liquid as far as possible from exposure to the air of the place where the bottling is carried on. It is of course desirable also to prevent the waste of the liquid which frequently occurs through the filling of the bottles to overflowing. Some of these objects have been attained in part hitherto; but so far as I am aware no apparatus has been devised as yet which will enable all of these objects to be attained in a satisfactory manner. Thus it has been sought to maintain the pressure on the liquid and to prevent the waste of liquid by providing in addition to the filling-tube a second tube, which returns or conducts to the barrel or other supply vessel the air displaced from the bottle, but this alone is not altogether satisfactory. It has also been proposed to maintain the required pressure of carbonic acid gas in the keg or barrel in which the liquid is delivered to the bottler. This is possible sometimes; but in some cases it happens that the keg or barrel is not capable of standing the gas-pressure which is necessary to force the liquid into the bottles. I have sought to provide in the first place for the separation in large part of the air displaced in the bottles from whatever overflow of liquid there may be, and for the escape of the air from the apparatus, and the return of the liquid to the supply vessel. I have sought also to provide for the admission of gas to the supply vessel without interference with the escape of the air and the return of the overflow. Furthermore, I have sought to provide for the handling of the liquid under gas pressure, in the manner already referred to, in cases where the original keg or barrel is not calculated to withstand gas pressure and the liquid can be drawn therefrom only by gravity.

Patent No. 2630311A: Apparatus For Drying Hops

Today in 1953, US Patent 2630311 A was issued, an invention of Verlin A. Bloxham, for his “Apparatus For Drying Hops.” There’s no Abstract, but in the description it states that the “invention relates to an apparatus for drying hops. The apparatus commonly employed heretofore for drying hops includes a house-like structure having a reticulated floor upon which the hops are loaded. This floor may be some 20 feet above the ground. Beneath the floor is disposed a heater burning fuel of one sort or another. The products of combustion from the heater usually pass through a zig-Zag or similar arrangement of pipes. located perhaps 8 feet beneath the floor on the way to the chimney. Forced draft of air is not provided, but the house is built tall enough, compared to its section, to provide a stack effect.”

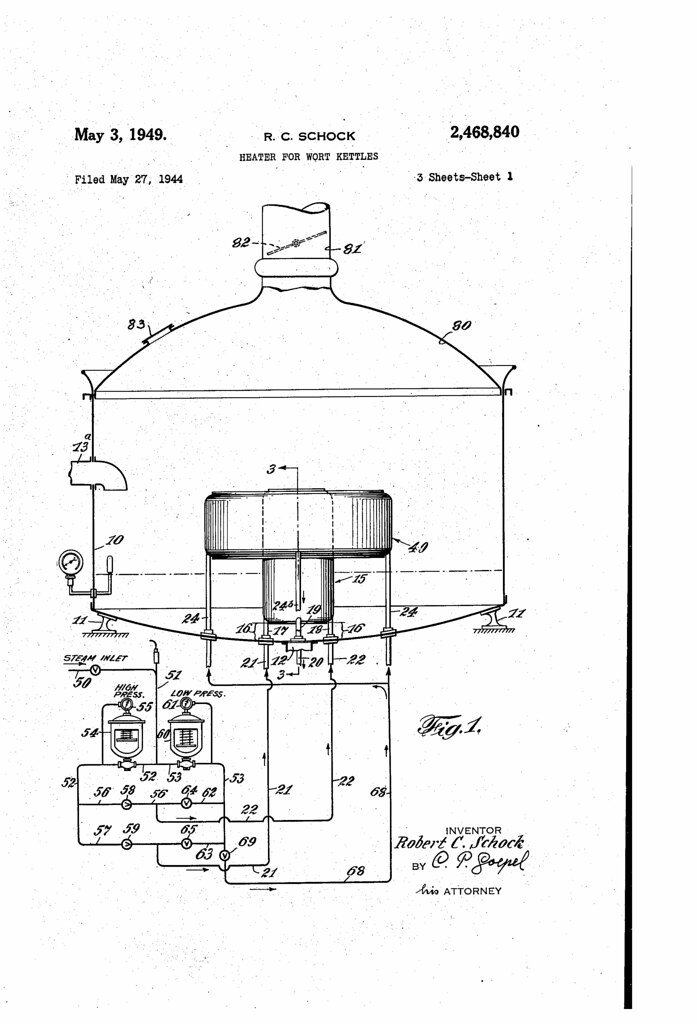

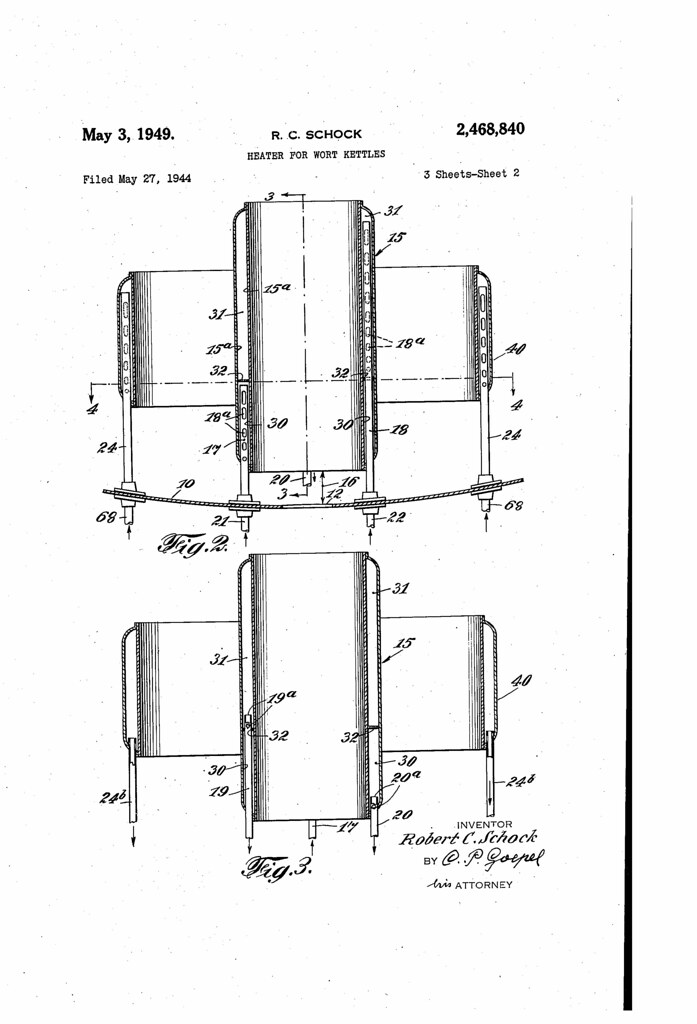

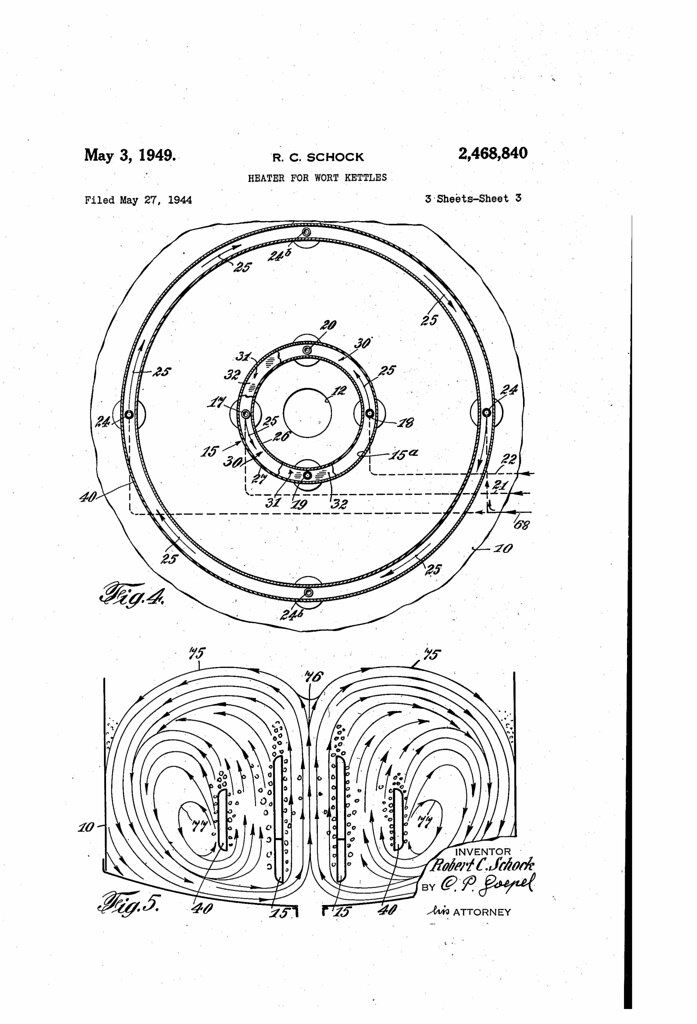

Patent No. 2468840A: Heater For Wort Kettles

Today in 1949, US Patent 2468840 A was issued, an invention of Robert C. Schock, for his “Heater For Wort Kettles.” There’s no Abstract, but in the description it states that the “invention relates to means and methods of heating wort prior to its use in the making of beer.” A little later on, they add that the “invention comprises a heating unit having varying heat units supplied to it for their exchange with a mass to be heated, and to keep said mass heated, such exchange taking place at relatively lower temperatures, then at relatively higher temperatures, and then again at lower temperatures, the latter if desired.”

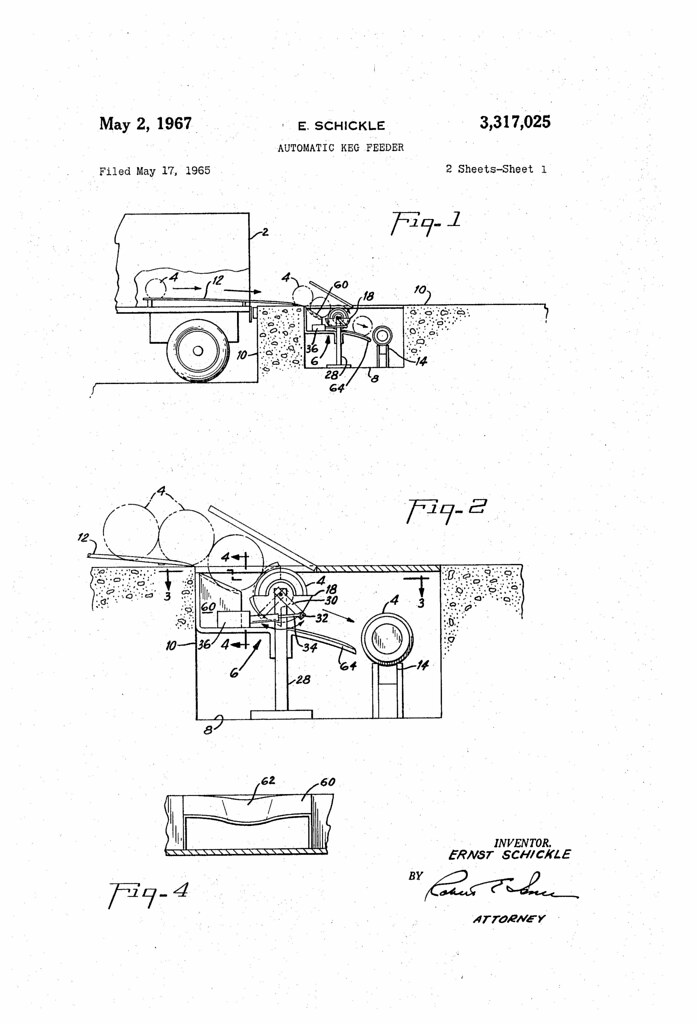

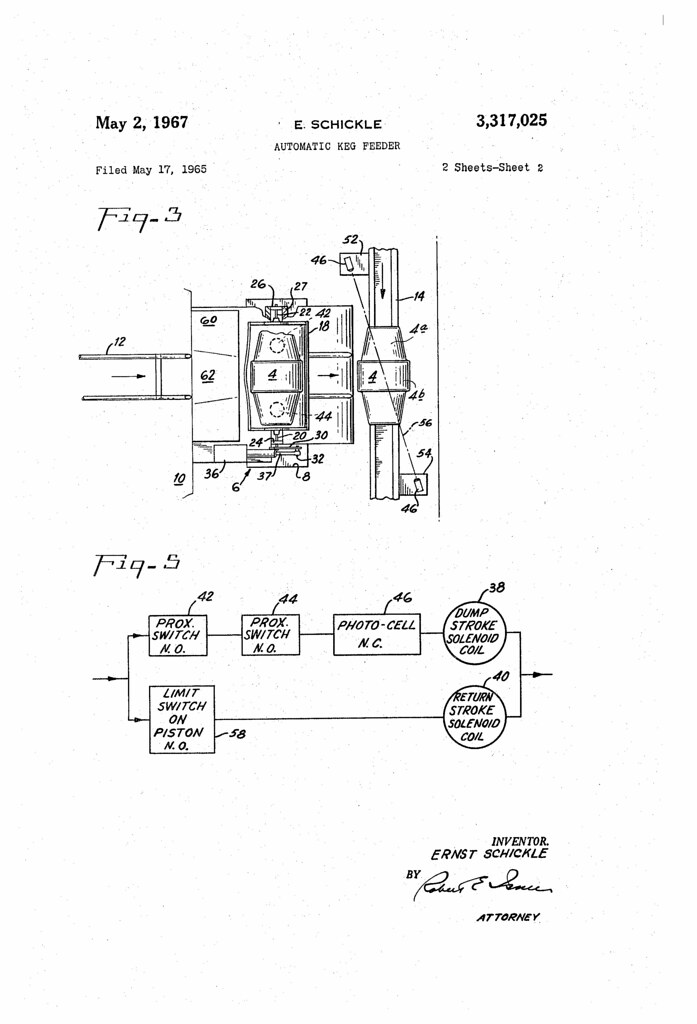

Patent No. 3317025A: Automatic Keg Feeder

Today in 1967, US Patent 3317025 A was issued, an invention of Ernst Schickle, assigned to Rheingold Breweries, for his “Automatic Keg Feeder.” There’s no Abstract, but in the description it states that the “invention relates generally to brewery operation and particularly to an improved apparatus for effecting transfer and controlled delivery of beer kegs or similar containers from a feeder location to an operating location.” A little later on, they add that the “invention may be briefly described as an improved beer keg transfer and delivery apparatus which includes, in its broad aspects, a keg receiving and neonmulating conveyor, a keg transfer unit, a delivery conveyor and associated means for effecting controlled keg delivery in spaced relation onto the delivery conveyor.”

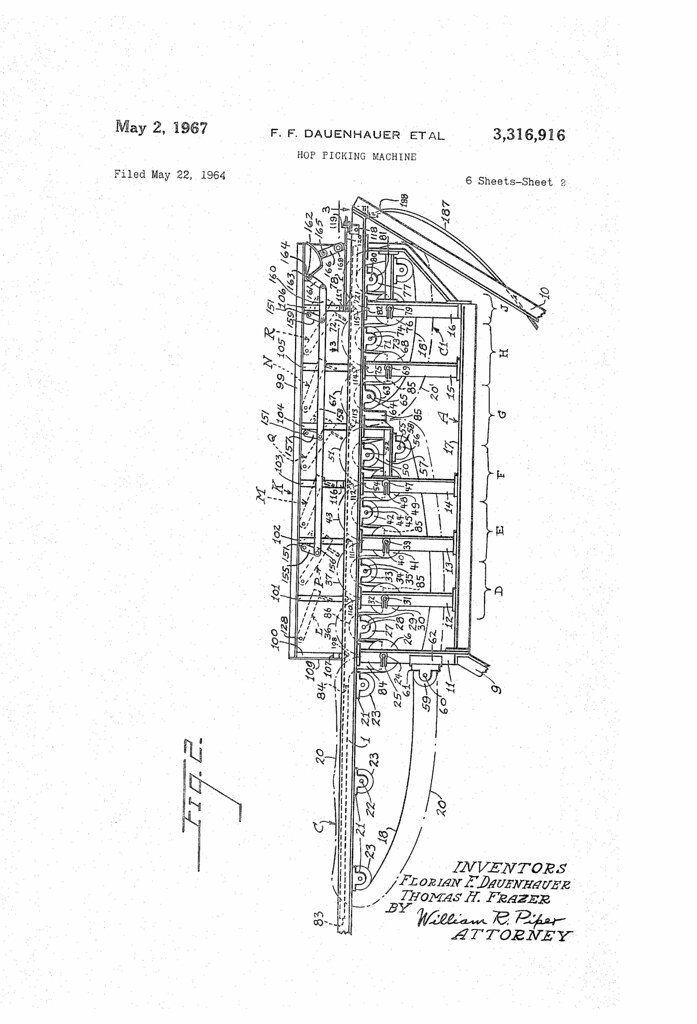

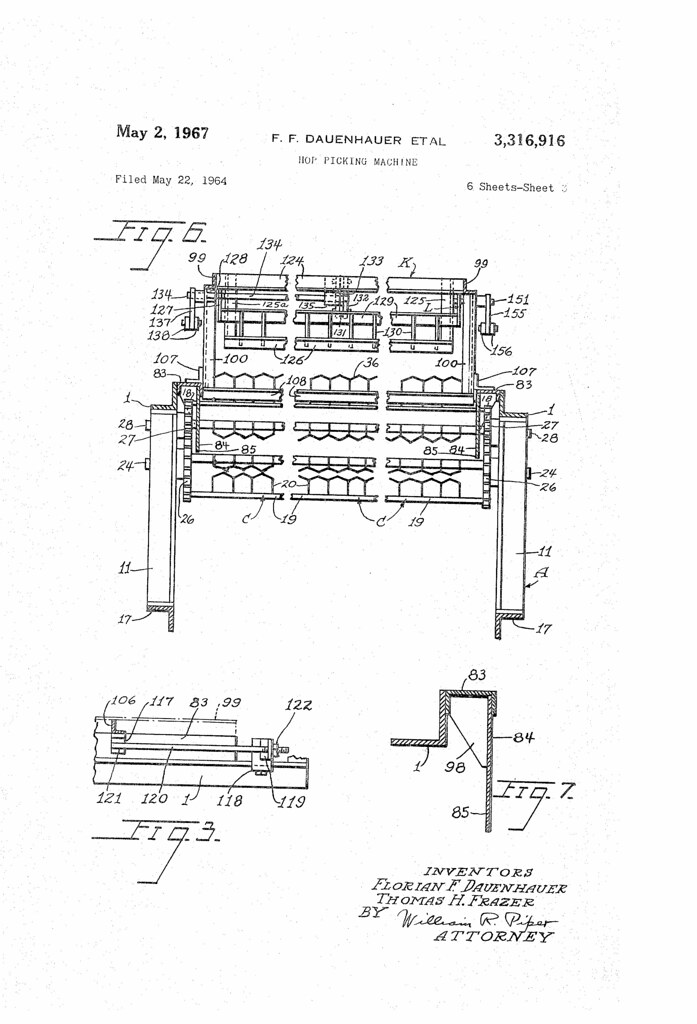

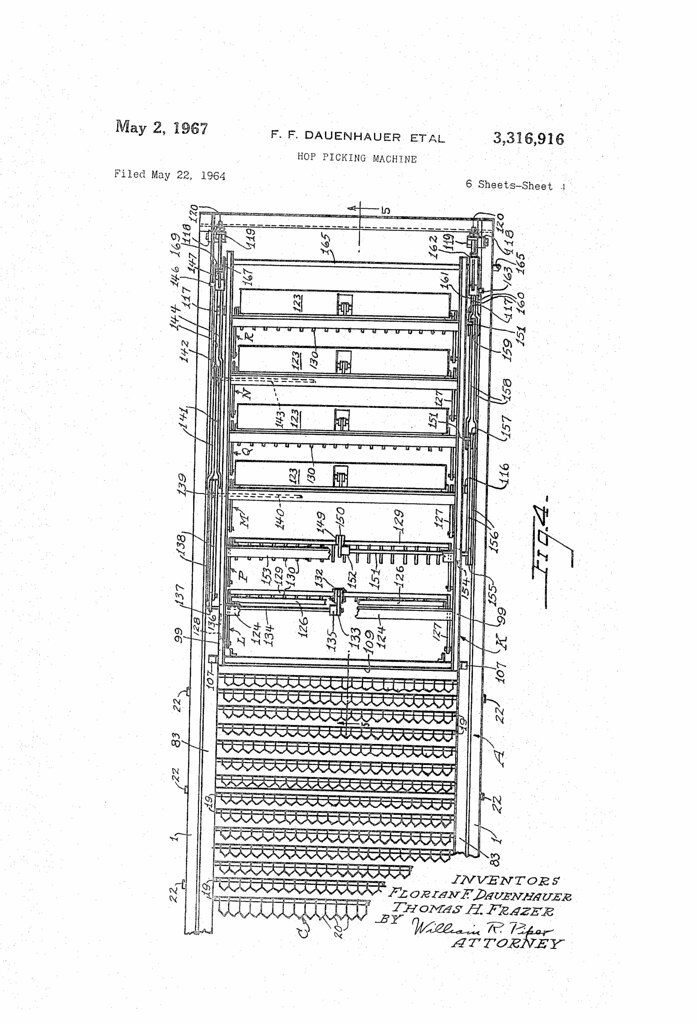

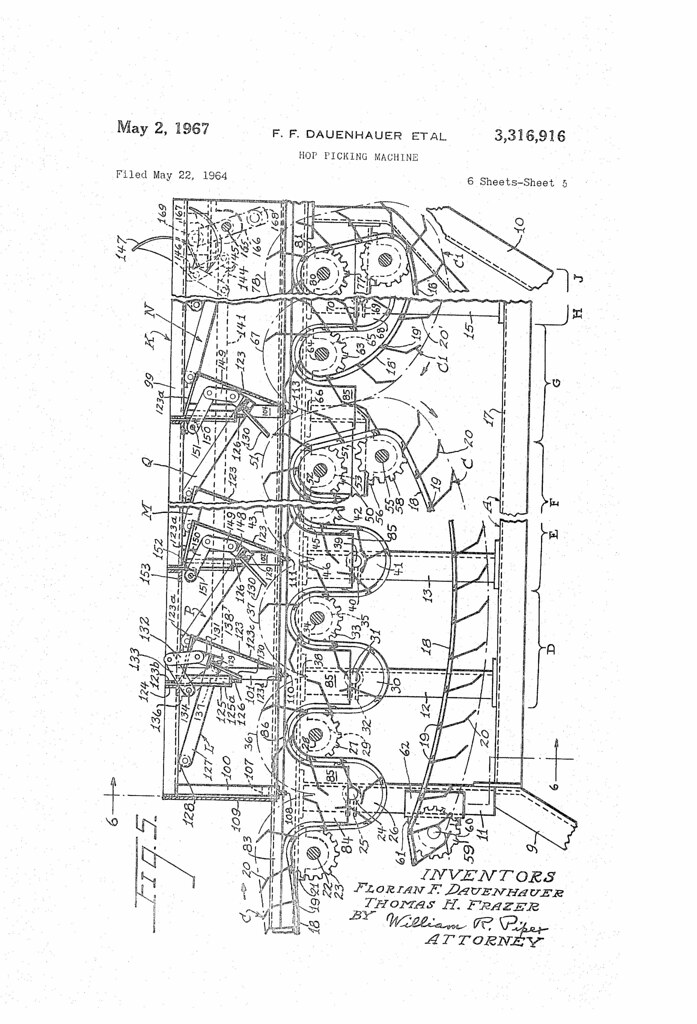

Patent No. 3316916A: Hop Picking Machine

Today in 1967, US Patent 3316916 A was issued, an invention of Florian F. Dauenhauer and Thomas H. Frazer, for their “Hop Picking Machine.” There’s no Abstract, and all they say in the description is a generic the “present invention relates to improvements in a hop picking machine, and it consists in the combination, construction and arrangement of parts as hereinafter described and claimed.” Which isn’t much for such a complicated machine, but you can get a better sense of it reading through the lengthy full description.

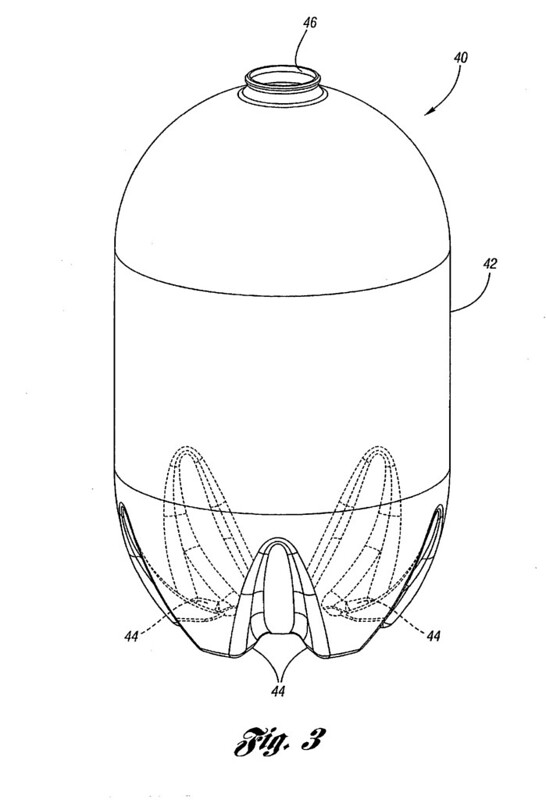

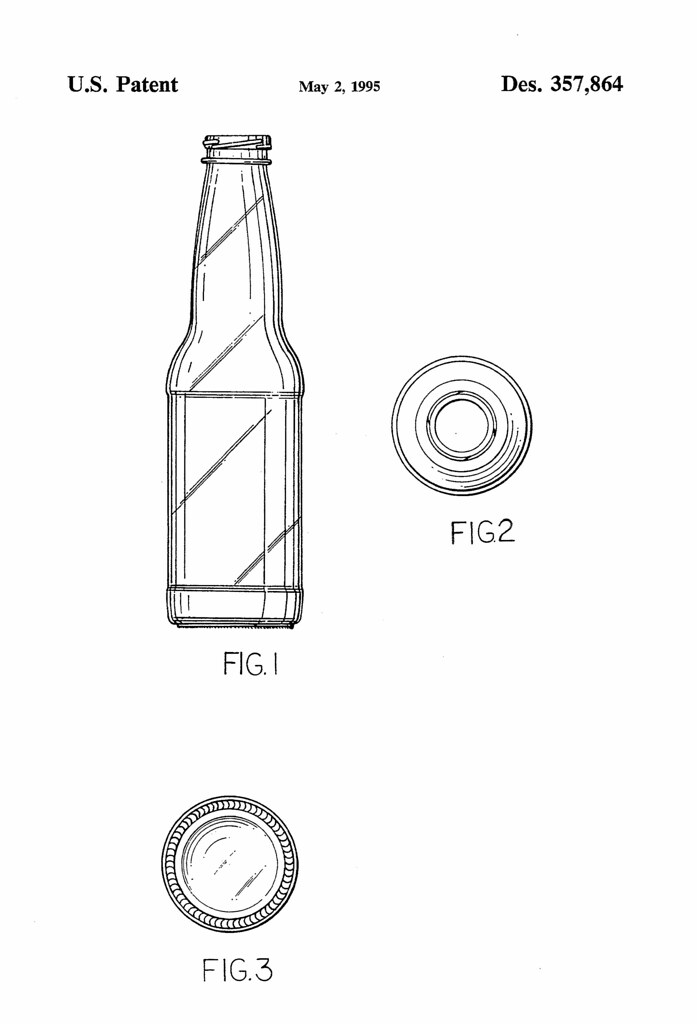

Patent No. D357864S: Beverage Bottle

Today in 1995, US Patent D357864 S was issued, an invention of Kevin R. Rusnock and Barbara E. Lee, assigned to the Coors Brewing Company, for their “Beverage Bottle.” There’s no Abstract, but all they say in the description is that it’s an “ornamental design for a beverage bottle.” Coors also refers to it as “our new design,” but I honestly can’t see what’s unique about it, at least not in the drawing they submitted with the patent application.

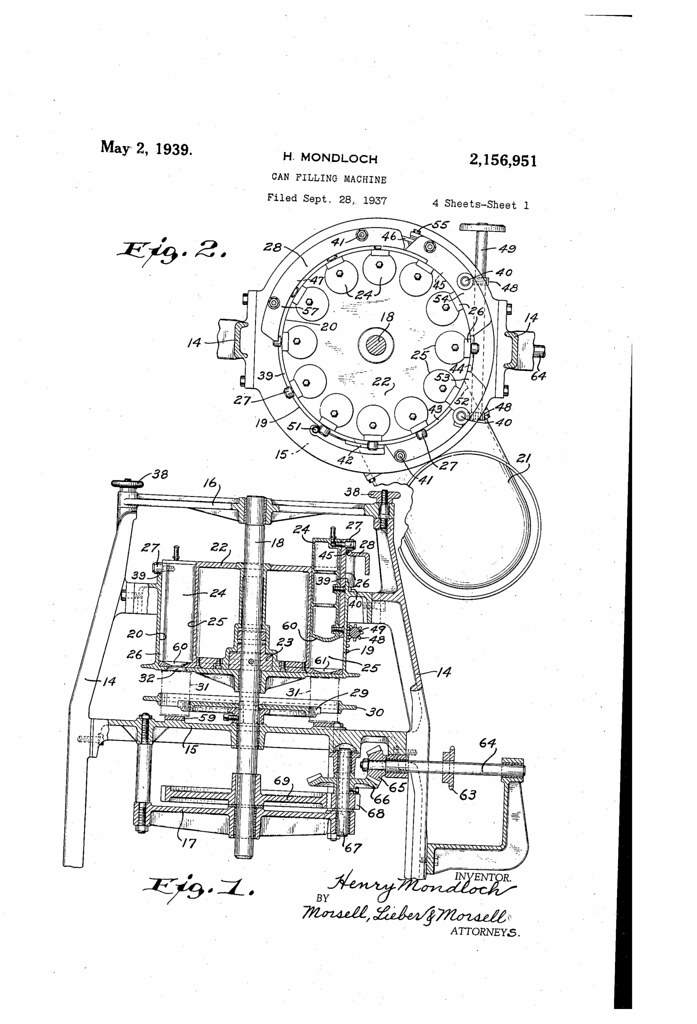

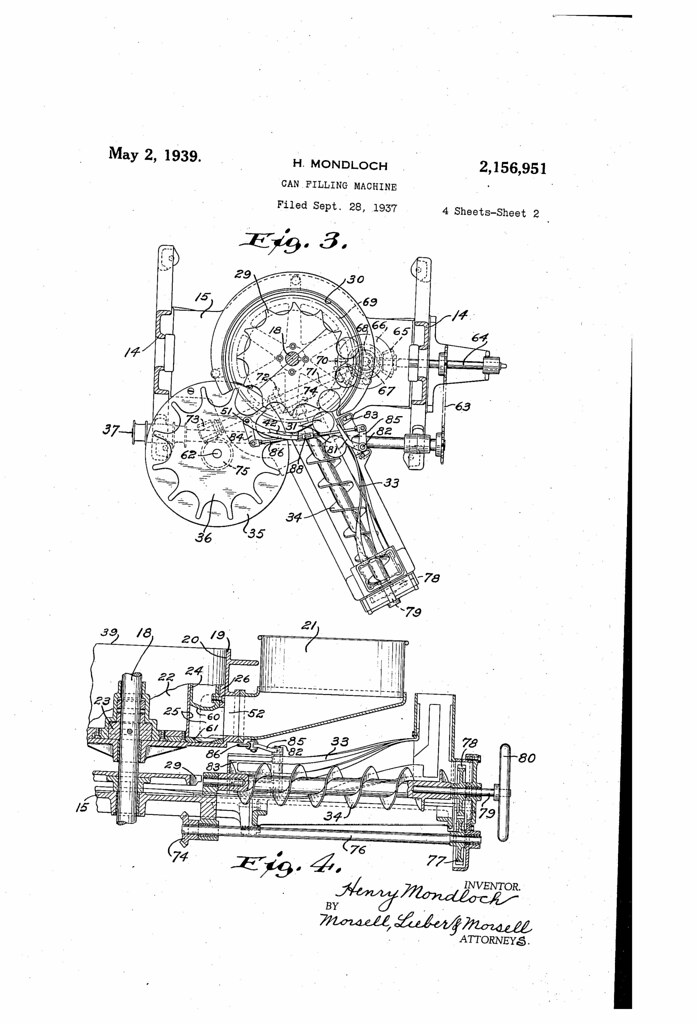

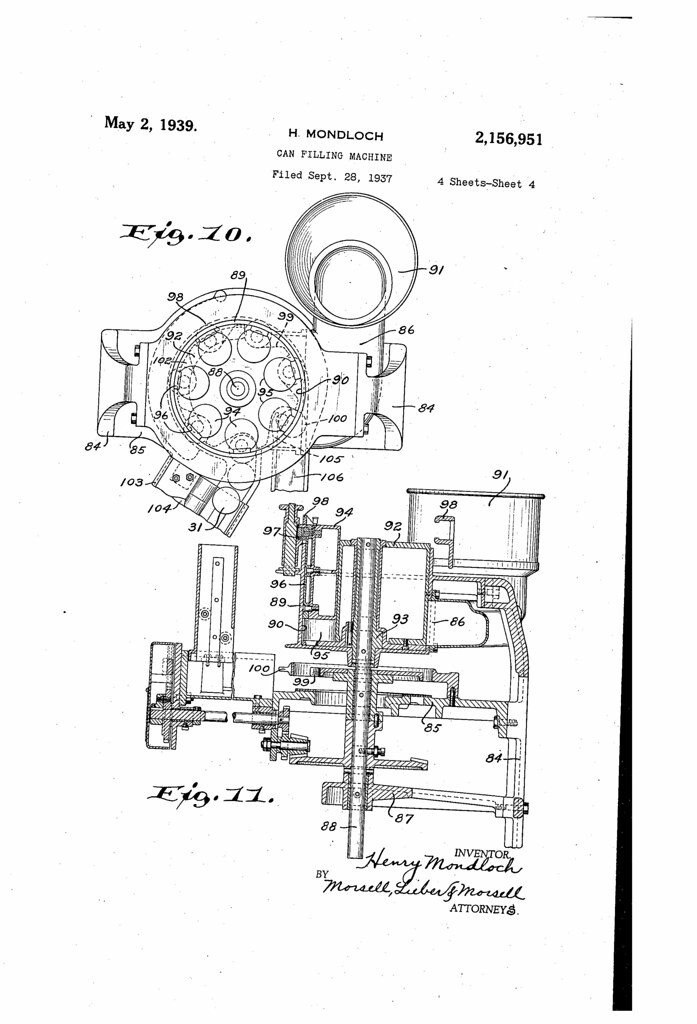

Patent No. 2156951A: Can Filling Machine

Today in 1939, US Patent 2156951 A was issued, an invention of Henry Mondloch, assigned to the Hansen Canning Machinery Corp., for his “Can Filling Machine.” There’s no Abstract, but they state in the description that the “present invention relates generally to improvements in the art of packing successive batches of commodity in receptacles, and relates more specifically to improvements in the construction and operation of so-called can filling machines of the automatic type.”

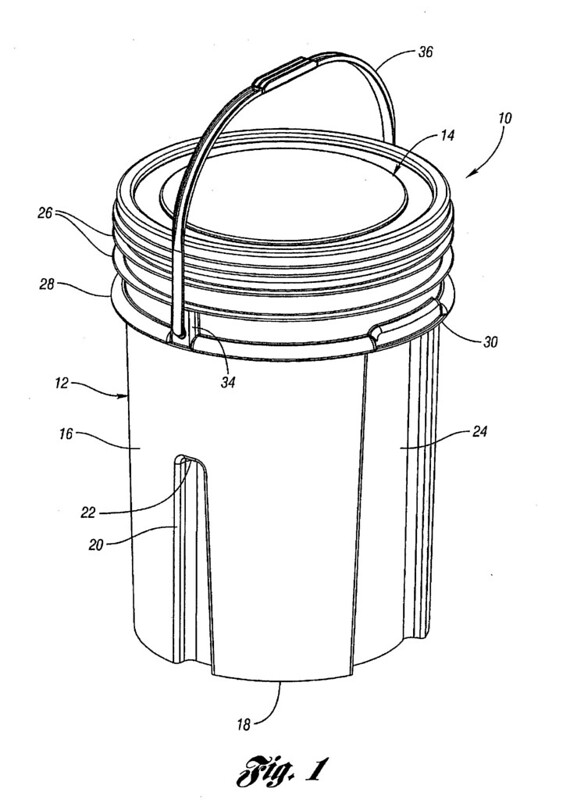

Patent No. EP2172402B1: Plastic Beer Keg

Today in 2013, US Patent EP 2172402 B1 was issued, an invention of William P. Apps, assigned to the Rehrig Pacific Company, for his “Plastic Beer Keg.” There’s no Abstract, but they state in the description that the “present invention relates generally to large multiple serving beverage containers, in particular, beer kegs.” They also list 13 claims about why this invention is unique, but the main one, of course, is that these are plastic, which is far cheaper than the stainless steel ones that are used today, and are also prone to theft. It will be interesting to see if they catch on.