Today in 1979, US Patent 3505946 A was issued, an invention of Peter D. Bayne and John L. Pahlow, assigned to Schlitz Brewing Co., for his “Apparatus For Reconstituting Concentrated Wort.” There’s no Abstract, although in the description it includes this summary:

This invention relates to a process of brewing and more particularly to a process and apparatus for reconstituting concentrated brewers wort.

Wort concentration has great potential and can offer advantages by increasing the production efficiency of existing plants, increasing production volume without a corresponding increase in capital expenditure and providing a simplification of both production processes and control of product uniformity without sacrificing quality of product.

More specifically, concentrated wort provides several distinct advantages. Brewhouse equipment generally works at peak capacity for only a few months of the year. By concentrating wort during off season periods a more efficient use of the facility results so that the brewhouse equipment can be used more efficiently throughout the year.

In addition, concentrated wort can be shipped to distant points where it can be reconstituted, fermented, finished in plants which can be built at relatively low cost because they do not require the expensive grain handling and brewhouse equipment. Moreover, weight savings can be realized by shipping the wort concentrate as opposed to shipping malt and raw grains required for conventional brewing.

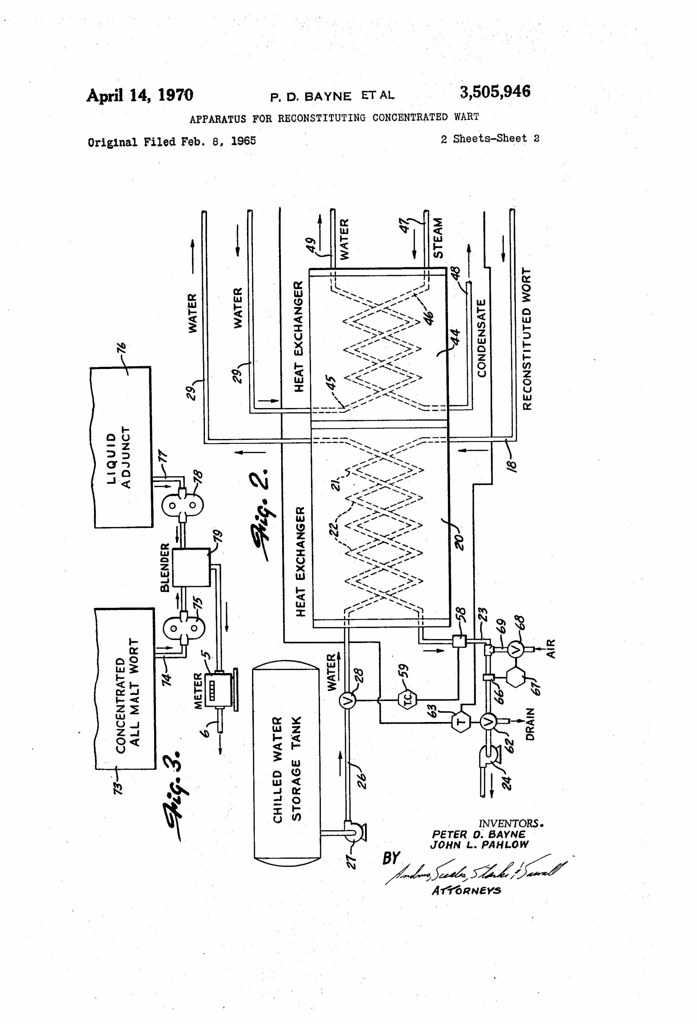

A system of wort concentration and reconstitution has outstanding potential in conjunction with a continuous or accumulated batch fermenting system. Wort concentrate is stable in storage and the concentrate can be metered into the present system in the desired flow rate, reconstituted, and then passed directly into the continuous fermenting system without storage. Using the reconstituting system of the invention in conjunction with a con tinuous fermentation process averts the necessity of holding the reconstituted wort at temperatures and under conditions which might create microbiological growth. Moreover, combining the reconstituting system with a continuous fermentation system completely eliminates the necessity of large storage tanks and chillers for maintaining a supply of wort for fermentation and provides a substantial cost saving in plant and equipment design over that of conventional systems.

The concept of wort concentration provides an alternate approach to the problems that some brewers have attempted to solve by freeze concentration of beer. Wort concentrate, because it does not contain alcohol, does not present the legal ramifications which accompany freeze concentrated beer.

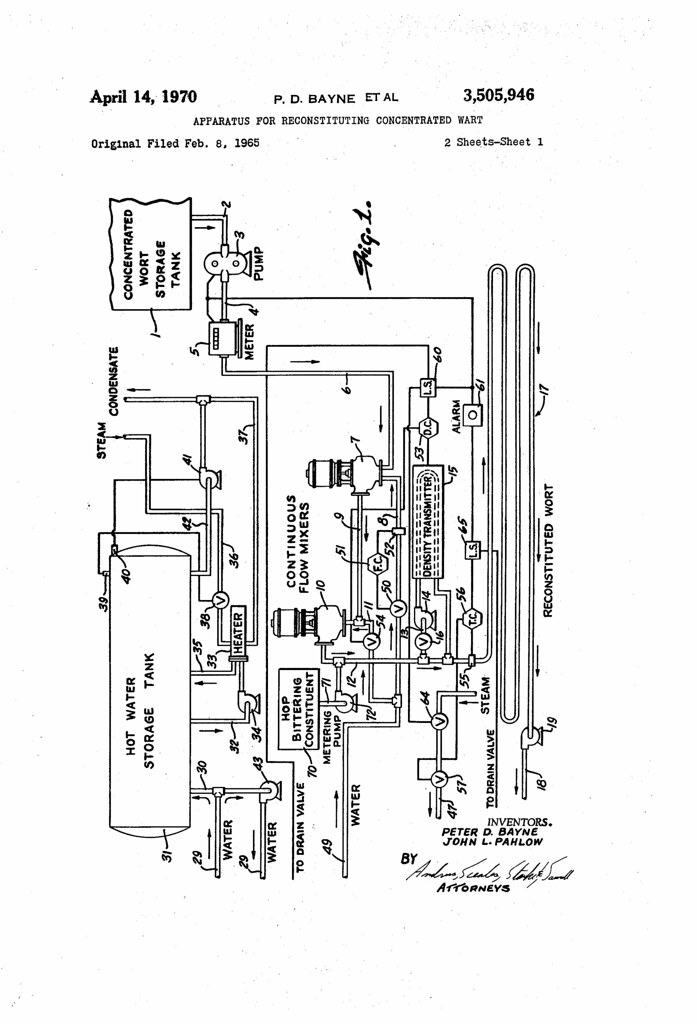

The present invention is directed to a continuous, high capacity process for reconstituting concentrated wort. The wort is reconstituted without color gain, loss of hop bitter or alteration of flavor. According to the invention, concentrated wort at a temperature of from 60 to F., but preferably under and having a solids content of 80% is continuously pumped from a storage tank and/or shipping containers and passed into a mixing system. Deionized water, or filtered mains water, depending upon the purity of the water, is introduced into a mixer at a constant flow rate and is mixed with the stream of concentrated wort to partially reconstitute or dilute the wort. In some cases, particularly in high capacity installations, a second mixer in series may be employed and a second stream of either deionized water or filtered mains water is introduced into the second mixer down stream from the first mixer. This second or breakdown stream of water is continuously introduced at a variable flow rate and mixed with the partially reconstituted wort to complete the reconstitution to the fermentation gravity.