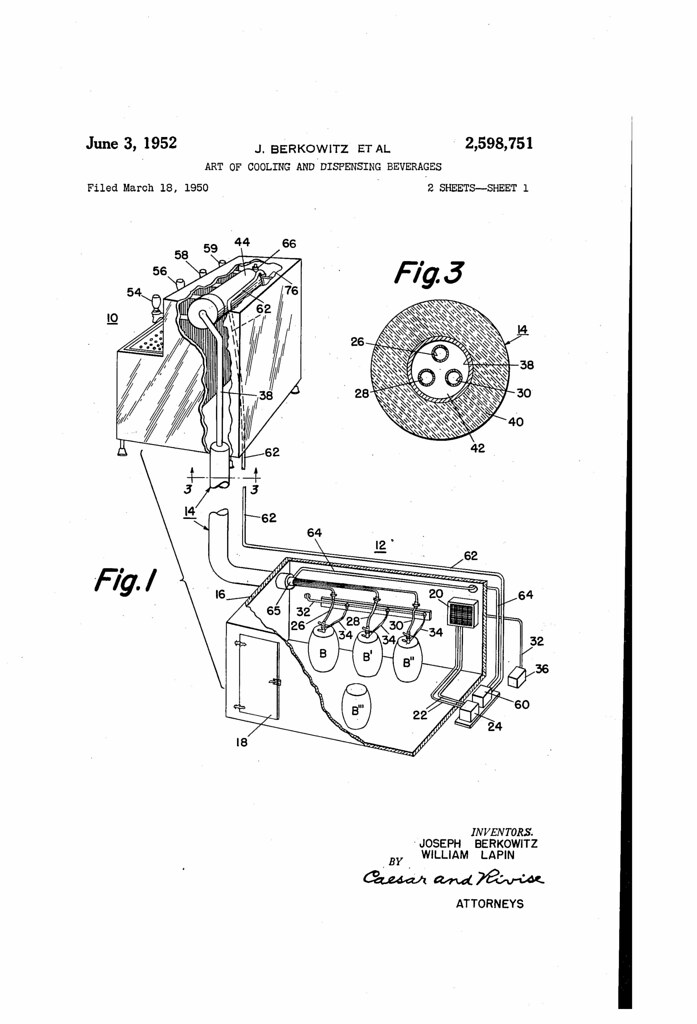

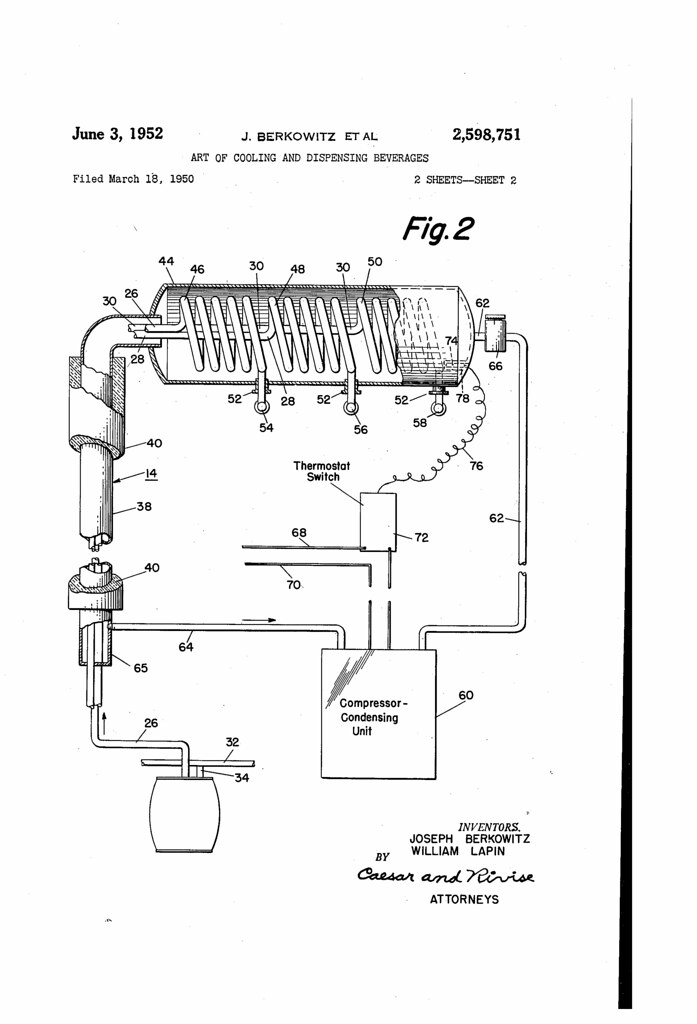

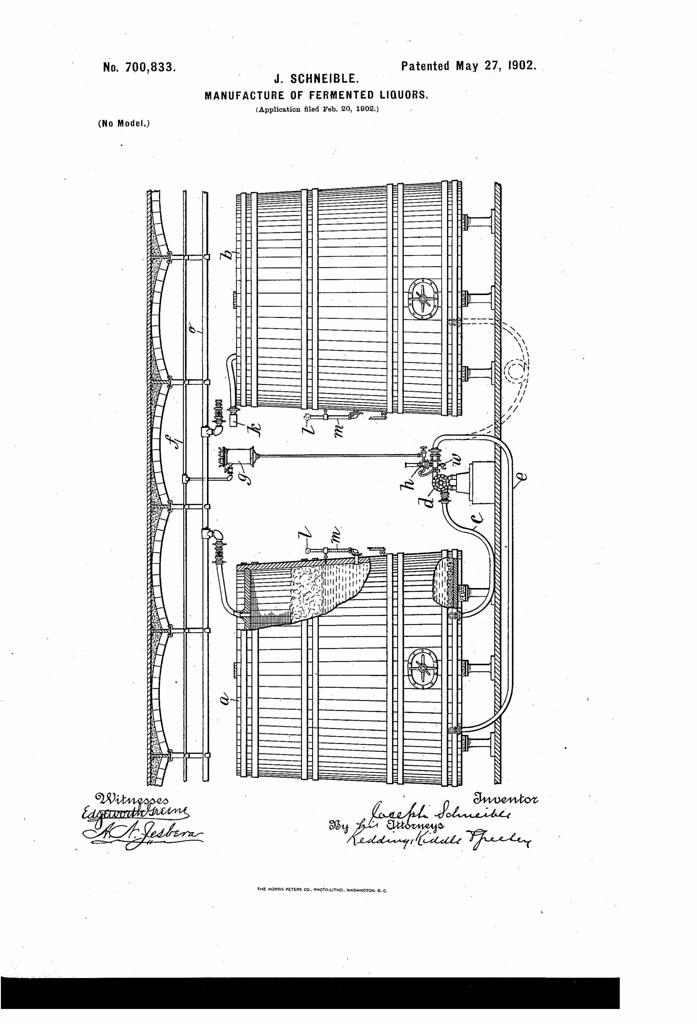

Today in 1952, US Patent 2598751 A was issued, an invention of Joseph Berkowitz and William Lapin, for their “Art of Cooling and Dispensing Beverages.” There’s no Abstract, though it’s described this way in the application:

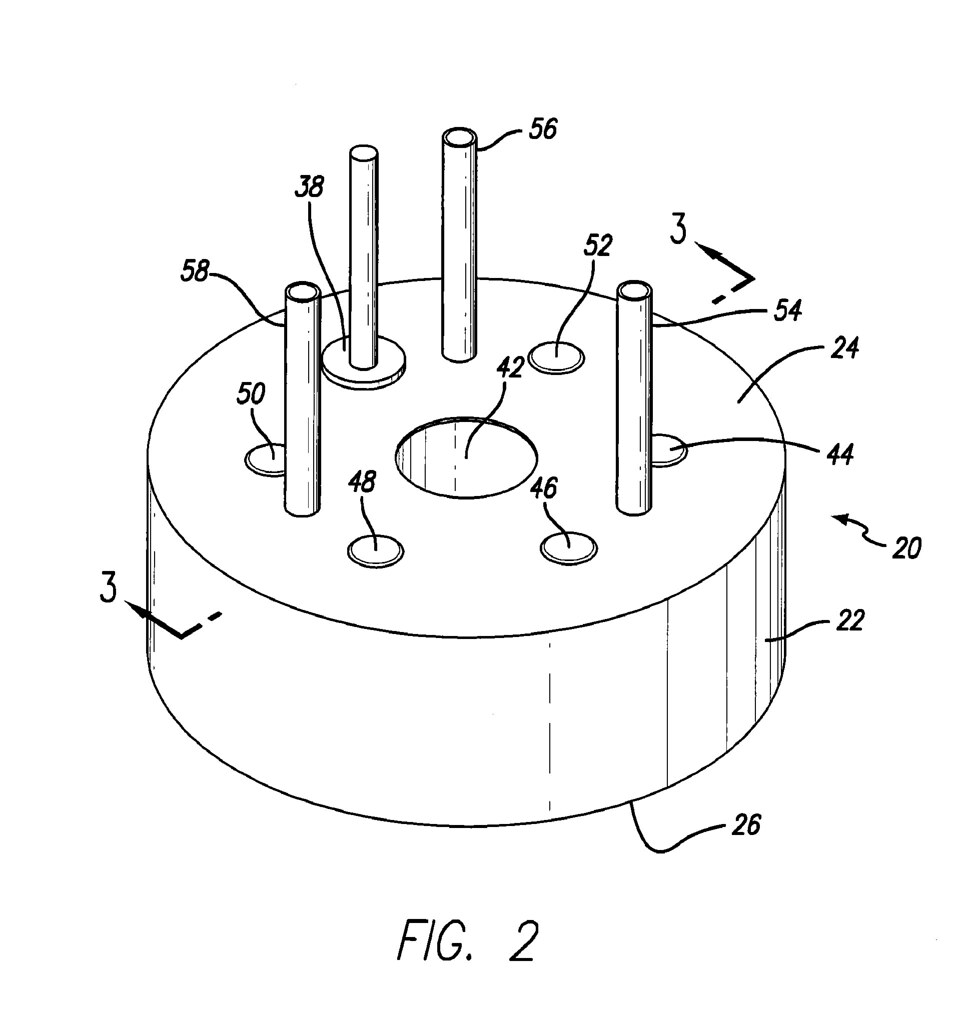

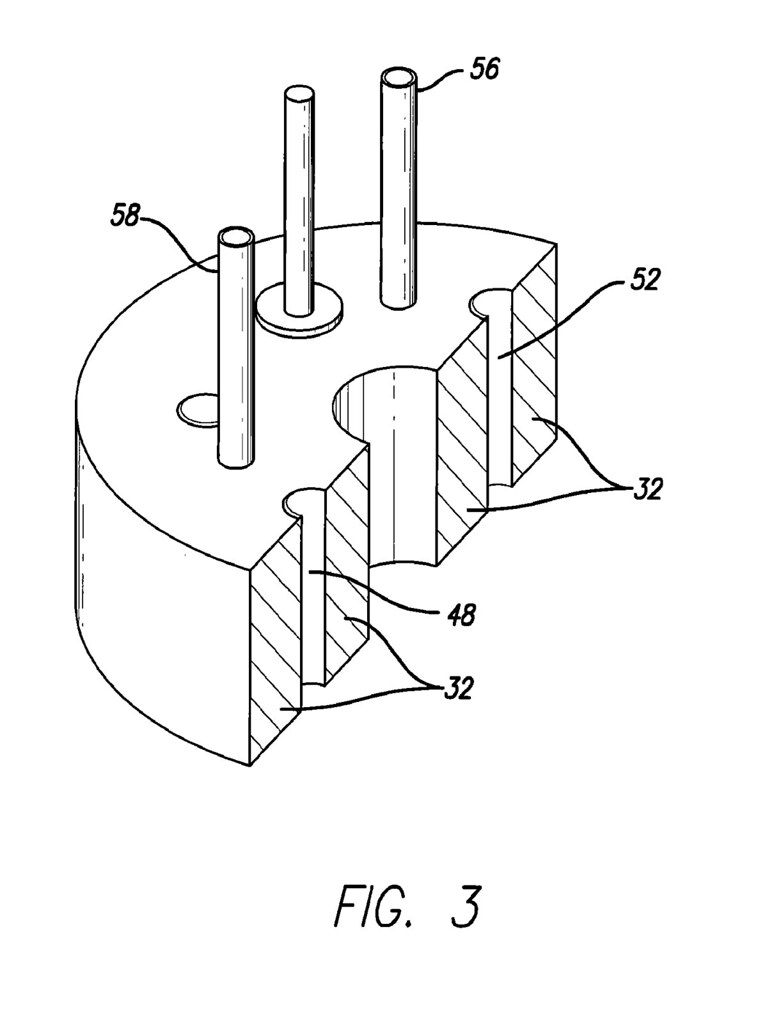

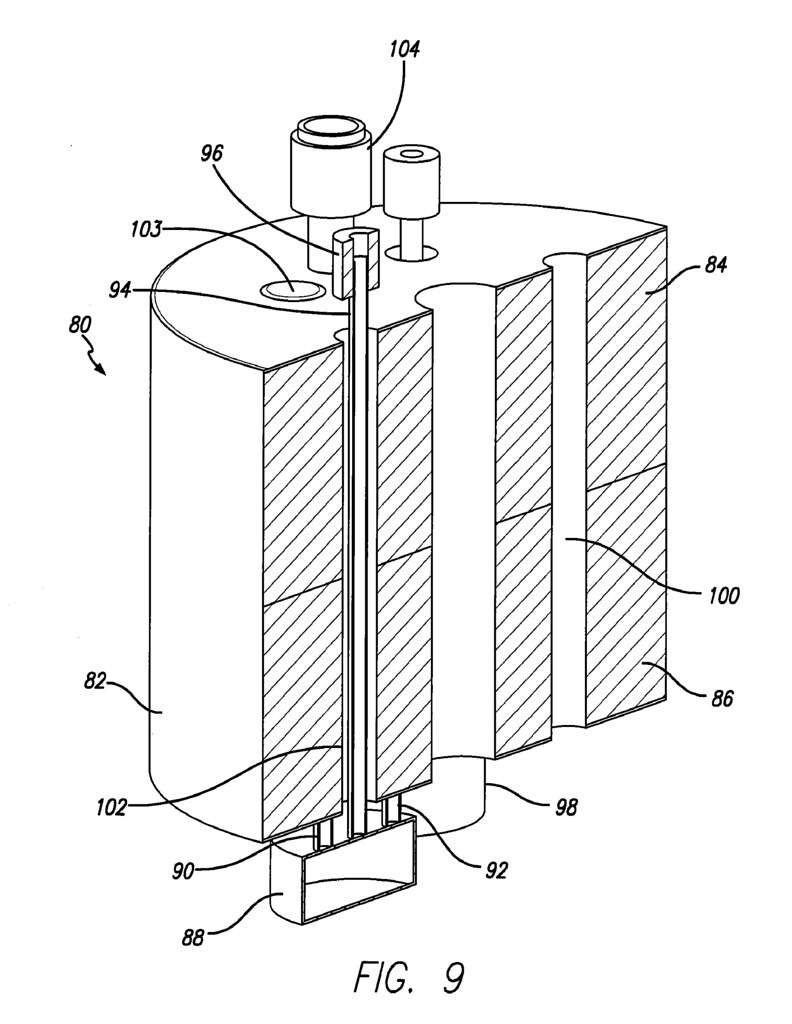

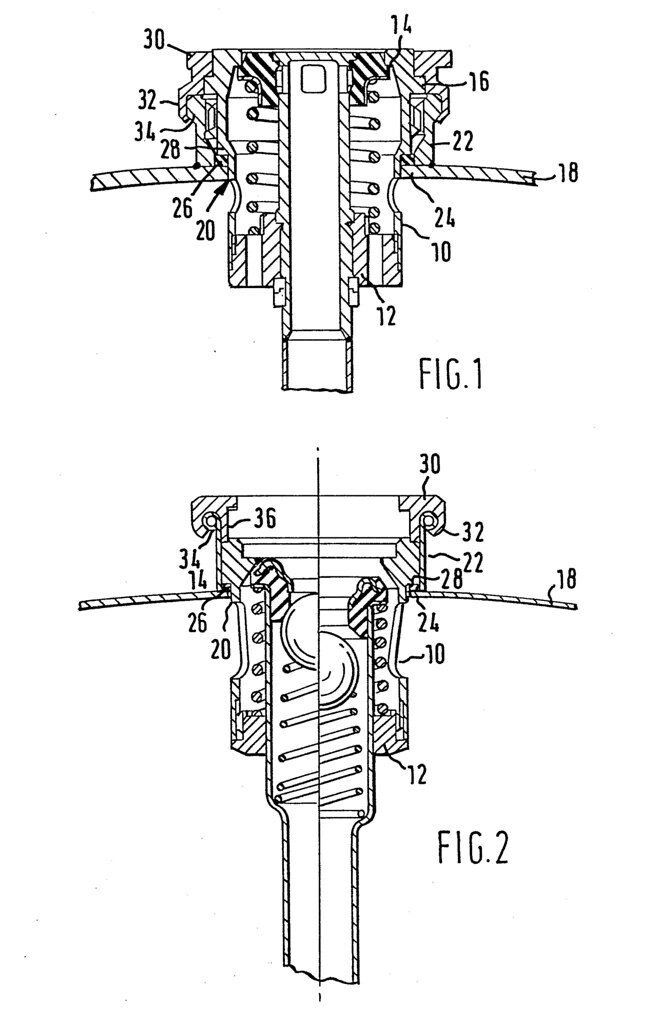

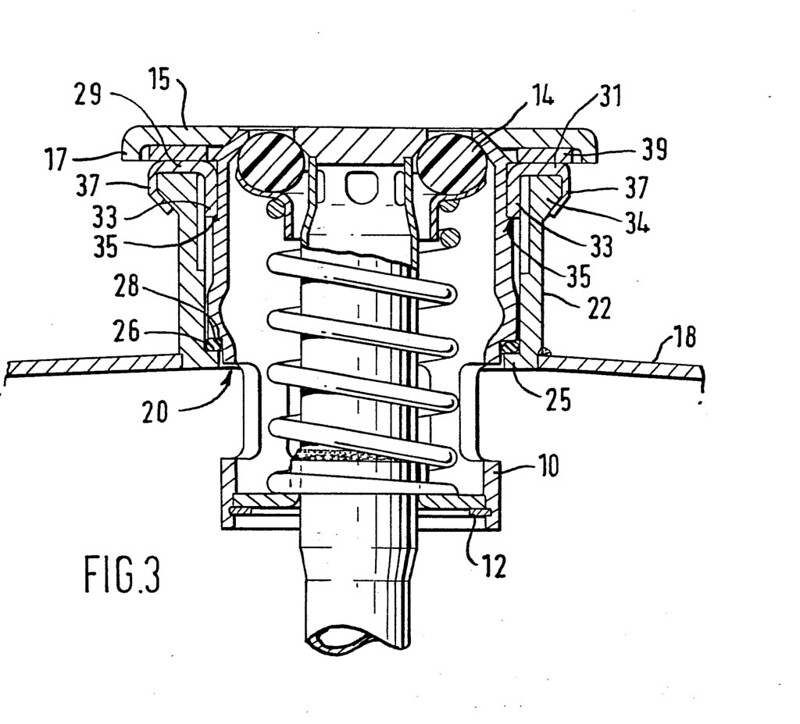

The apparatus of the invention in its essential details consists of a hermetically sealed tank, a liquid line from a compressor-condensing unit connected to said tank, an expansion valve near the juncture of said liquid line and tank, a hermetically sealed conduit also connected to said tank, a suction or return line from said conduit to said compressor-condensing unit, a beverage line encased by said conduit and extending into said tank, the free end of said beverage line extending through a wail of said tank, and being provided with a dispensing tap. The tank is preferably encased in a dispensing unit or cabinet of desired construction and design, and the source of beverage, e. g. barrels or kegs, may advantageously be housed in a storage chamber of the walk-in type, which is preferably cooled as by means of a diffuser or other refrigerating device.