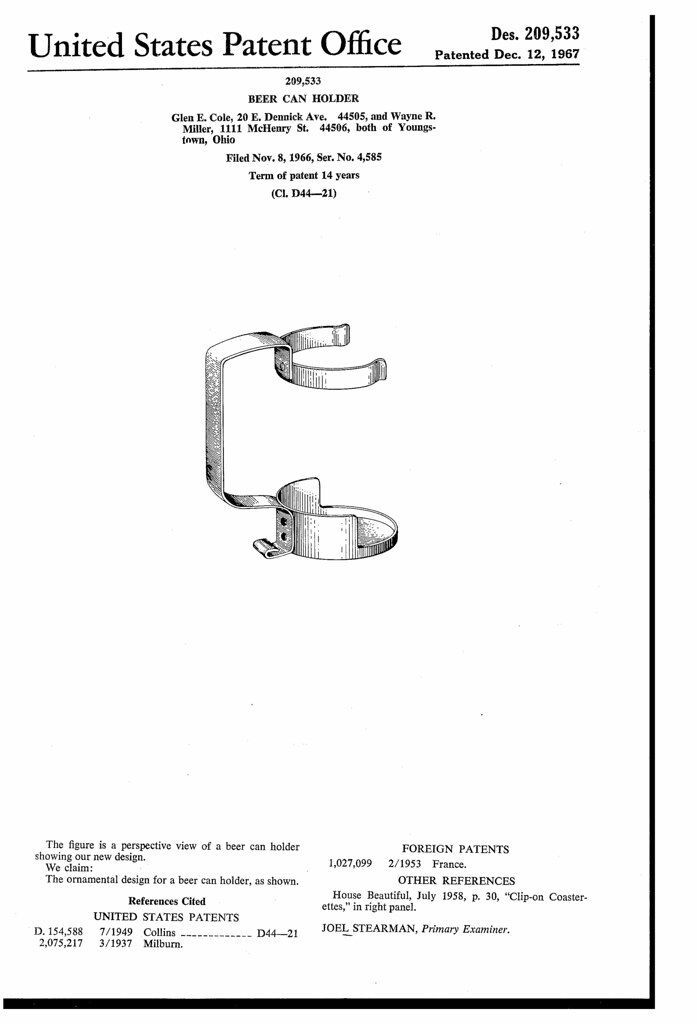

Today in 1967, US Patent D209533 S was issued, an invention of Glen E. Cole and Wayne Miller, for their “Beer Can Holder.” The text of their patent application is, in its entirety:

The ornamental design for a beer can holder, as shown.

>

>

By Jay Brooks

Today in 1967, US Patent D209533 S was issued, an invention of Glen E. Cole and Wayne Miller, for their “Beer Can Holder.” The text of their patent application is, in its entirety:

The ornamental design for a beer can holder, as shown.

>

>

By Jay Brooks

Today in 1871, US Patent 121902 A was issued, an invention of Jacob Seeger and John Boyd, for their “Improvement in Preserving and Using Hops in Brewing.” There’s no Abstract, although in the description it includes these claims:

It is well known that the active principle of hops is soon dissipated and the flavor changed or lost upon exposure to atmospheric action, and that, therefore, fresh hops command in the market two or three fold the price of hops grown the year previous. They are also readily injured by dampness, and their shipment by water is, therefore, attended with risk.

We propose by grinding or otherwise pulverizing the hops, and by then packing the same in air-tight packages to secure the following advantages in an improved article of manufacture and trade: First, the bulk is reduced at least fifty per cent. in packing the hops after being pulverized. Second, the hops pulverized and packed in air-tight vessels or packages may be stored for an indefinite length of time without deterioration as to quality, weight, or flavor. Third, the expense and labor of transportation is greatly reduced. Fourth, hops pulverized and packed in air-tight packages may be transported by Water-carriage without risk or damage by dampness. For the purpose of retail trade the pulverized hops are packed in cans or packages holding a pound, more or less, while for the convenience of large consumers, breweries, &c., the packages may be boxes or barrels. In packing pulverized hops the contents of an ordinary bale may be reduced to the dimensions of a flour-barrel, and, therefore, the labor of handling and the expense of transportation will be proportionately reduced.

The large consumer is enabled by our method to store his years supply without danger of deterioration as to quality, flavor, or weight, and with a material saving as to quantity required and space occupied. The dealer is enabled by our method to handle his hops and to ship them to any market without risk from atmospheric causes or dampness, which now makes a material advance in the price in markets remote from the place of production; or he can hold his stock over and wait an advance in price. This latter fact will tend to equalize prices and relieve the market of a glut at one time or a dearth at another.

By Jay Brooks

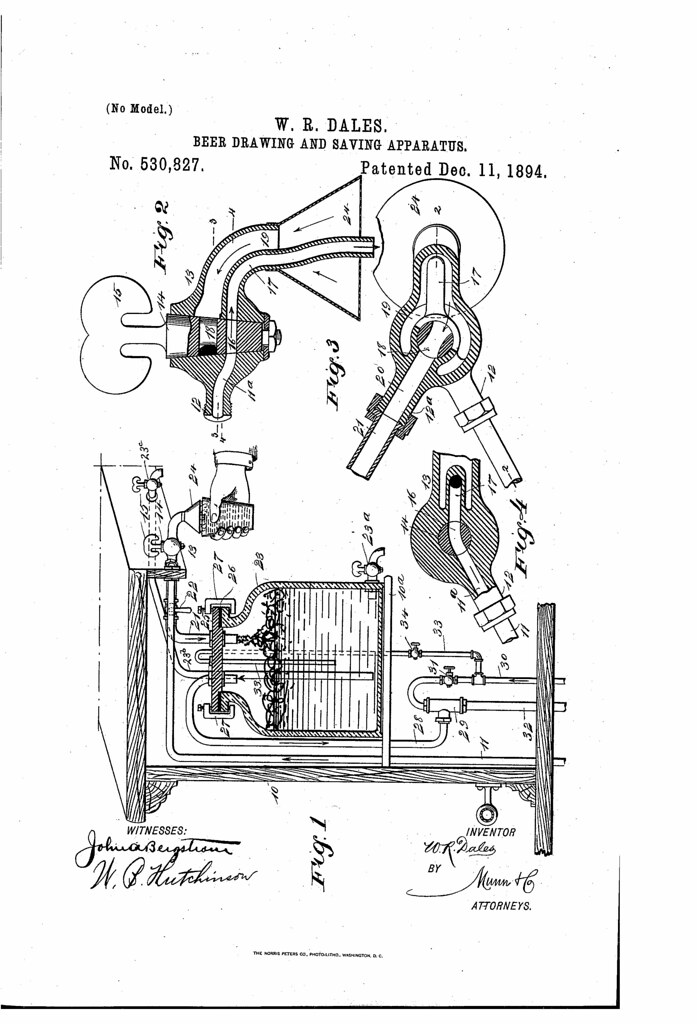

Today in 1894, US Patent 530827 A was issued, an invention of William R. Dales, for his “Beer Drawing and Saving Apparatus.” There’s no Abstract, although in the description it includes these claims:

The object of my invention is to produce an apparatus which enables beer to be readily drawn to fill a glass or other receptacle, and which has also an arrangement by which the froth may be sucked from the glass and delivered into a receptacle from which, after it settles, it may be withdrawn in the shape of merchantable beer. The apparatus thus provides for selling beer on draft in the usual way, while cans and such articles may be filled from the receptacle into which the froth has been delivered. To these ends my invention consists of certain features of construction and combinations of parts, which will be hereinafter described and claimed.

By Jay Brooks

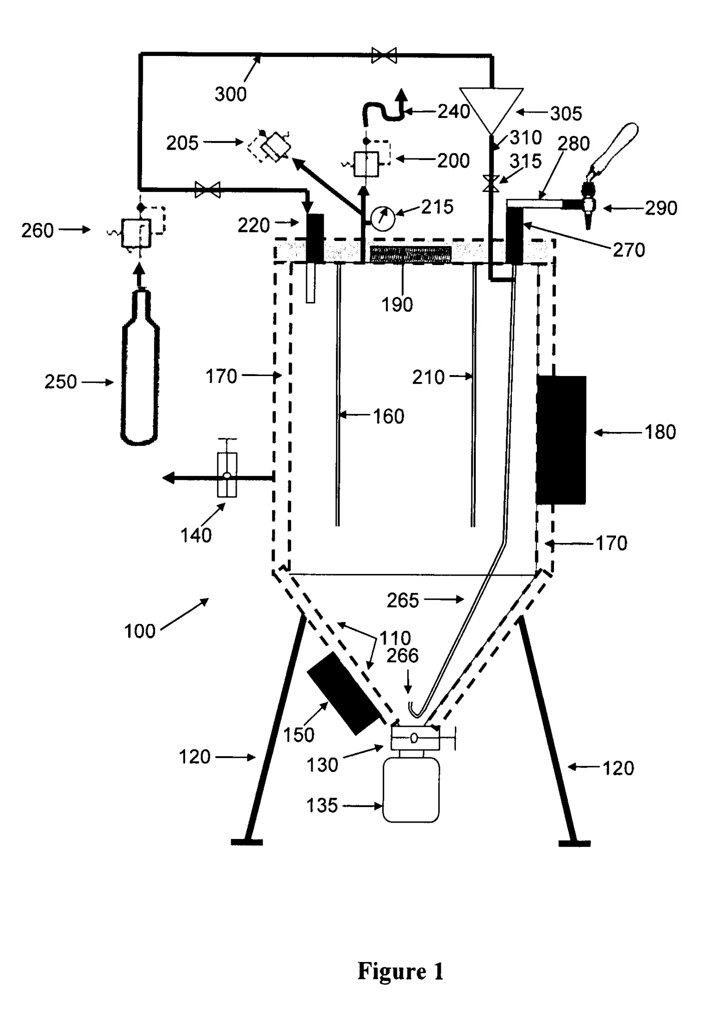

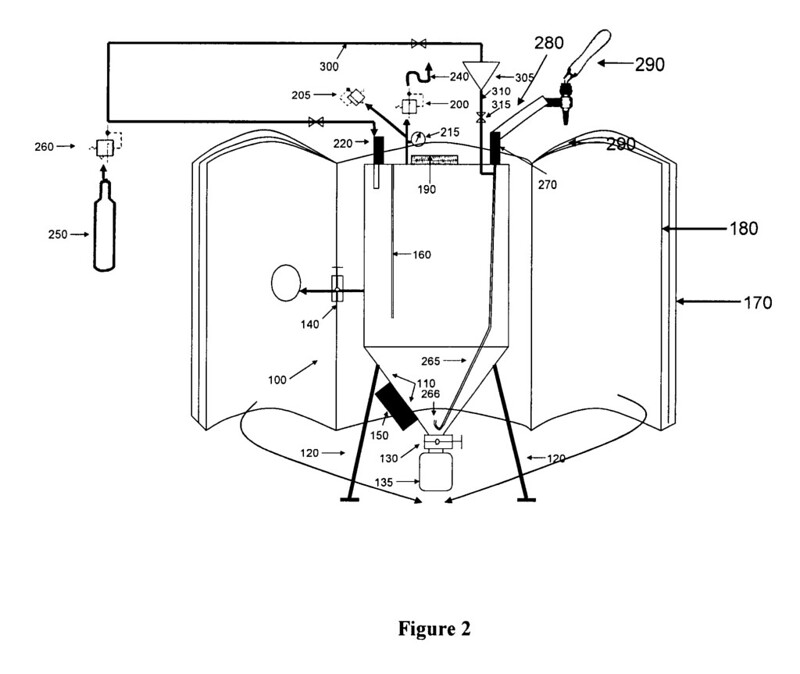

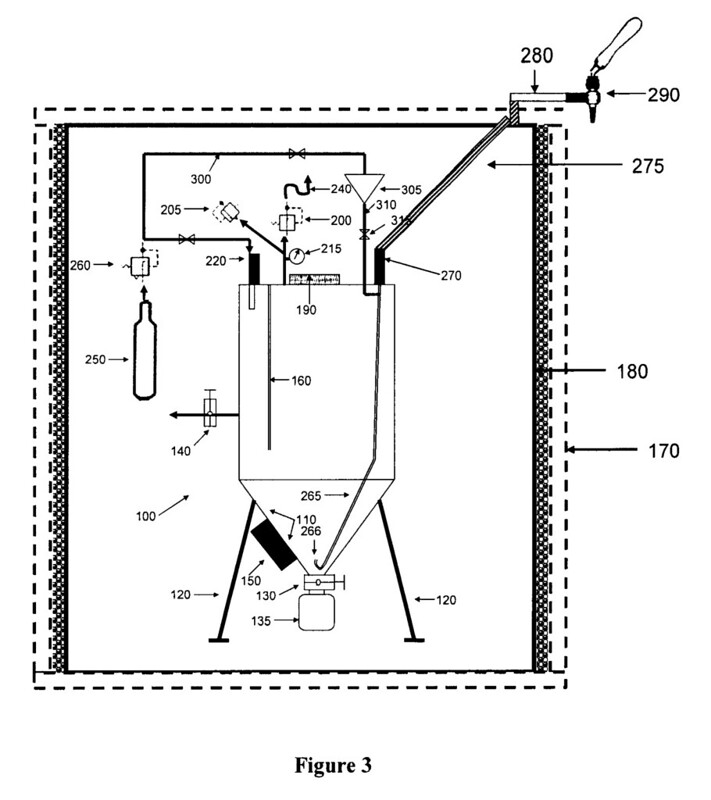

Today in 2013, US Patent 8601936 B2 was issued, an invention of Ian Stuart Williams and Anders Gordon Warn, assigned to Williamswarn Holdings Limited, for their “Combined Brewing System.” Here’s the Abstract:

A combined brewing system for small scale brewing of fermented alcoholic beverages, particularly beer, and to a method of making fermented alcoholic beverages. The brewing system comprises a single pressurizable vessel. The beer is naturally carbonated to the desired level during fermentation. Sediment is collected and substantially separated from within the vessel and removed from the vessel while the vessel is under pressure. Compressed gas is added for maintaining natural carbonation levels, so that the contents of the vessel can be drawn off at a desired pressure. The vessel has a temperature control system to selectively control the temperature during processing.

By Jay Brooks

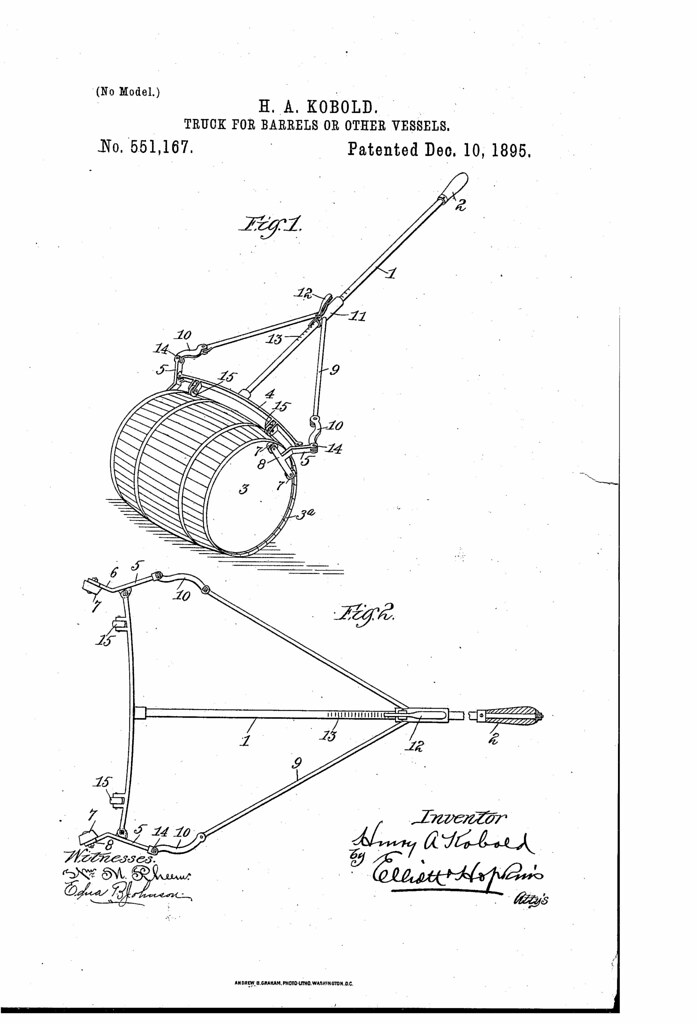

Today in 1895, US Patent 551167 A was issued, an invention of Henry A. Kobold, for his “Truck for Barrels or Other Vessels.” There’s no Abstract, although in the description it includes these claims:

My invention relates to a device for grasping kegs, barrels, casks, and other vessels having projecting flanges or rims at their ends like the chines of kegs and barrels, whereby the same may be conveniently and readily conveyed from place to place or raised and lowered along skids in loading and unloading without the necessity of touching the hands to them.

My invention has for its primary object to provide a device of this nature which Will be capable of readily grasping the vessel in such a manner that the latter may be easily rolled and guided to the desired place, the cylindrical form of the vessel being utilized in giving it locomotion.

By Jay Brooks

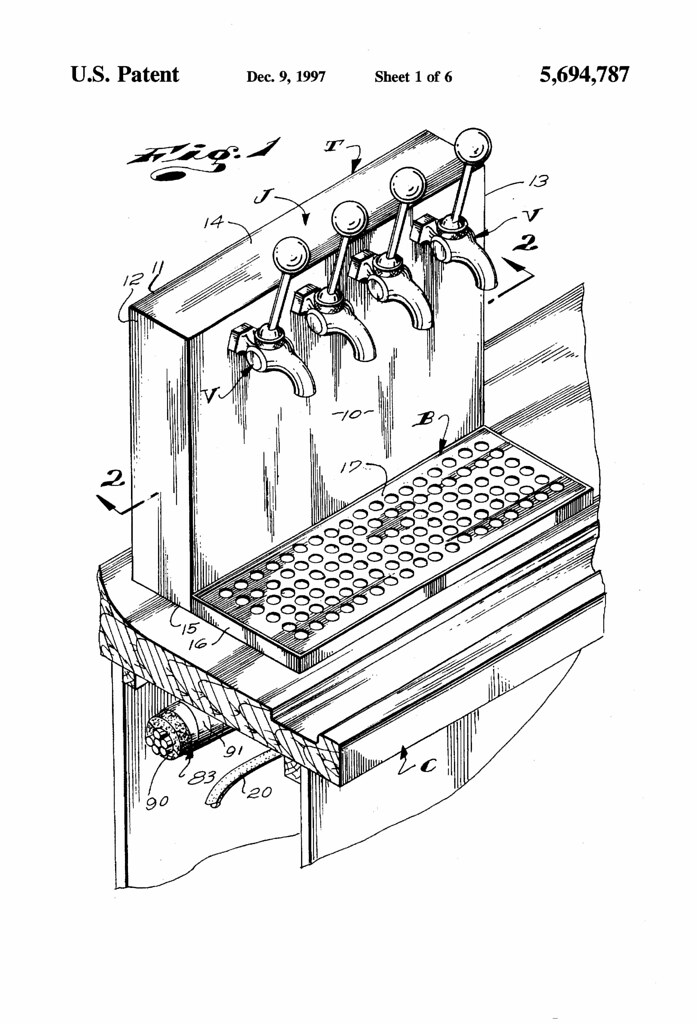

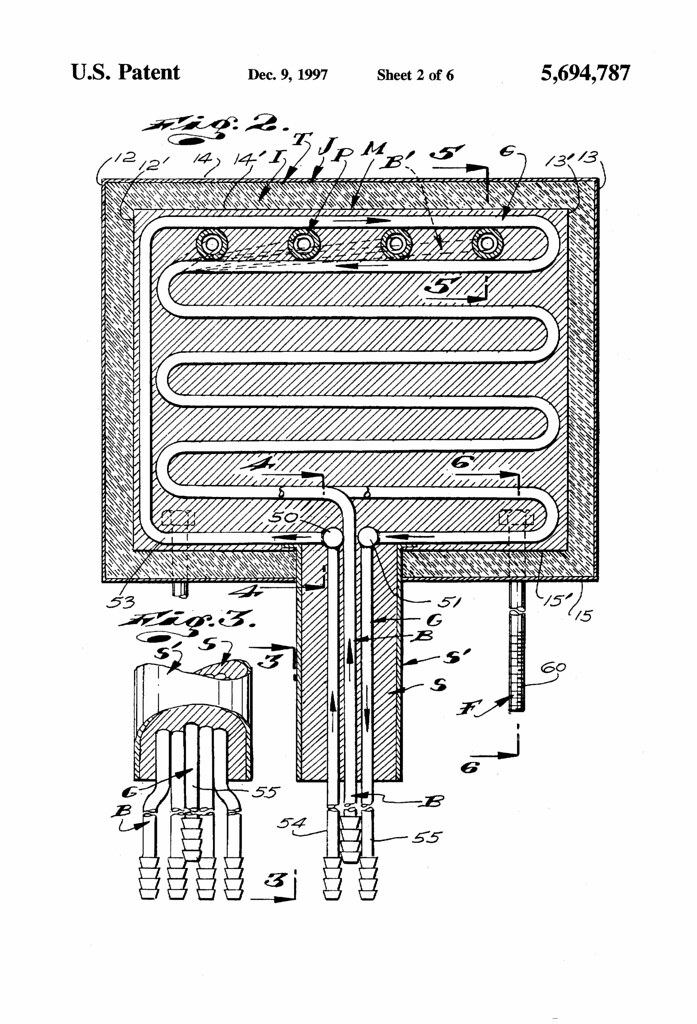

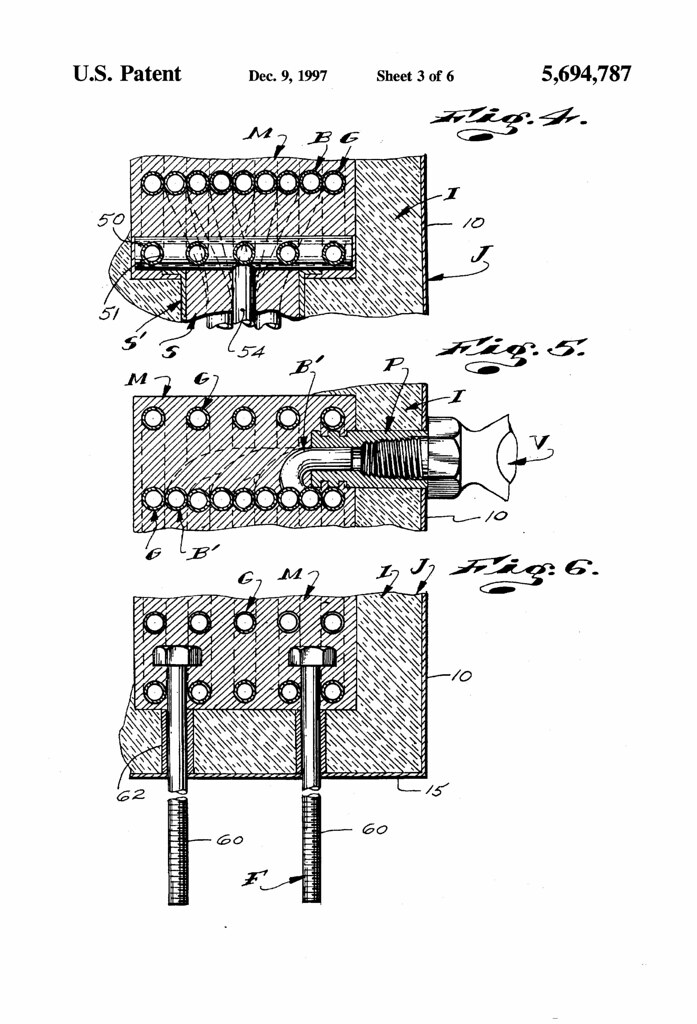

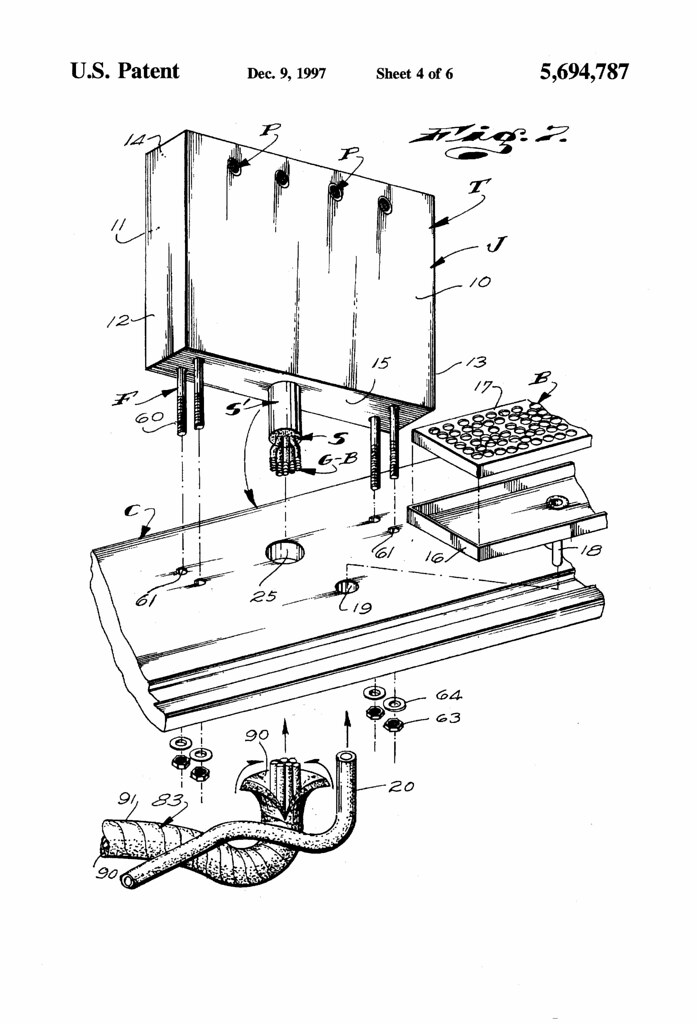

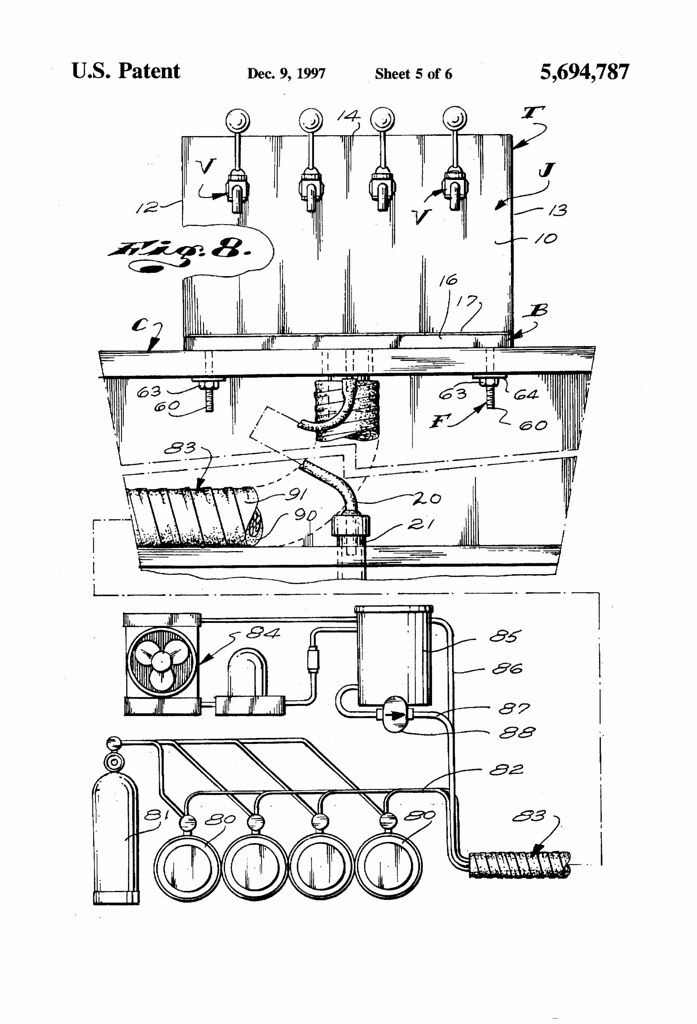

Today in 1997, US Patent 5694787 A was issued, an invention of Robert K. Cleleand and James M. Cleleand, for their “Counter Top Beer Chilling Dispensing Tower.” Here’s the Abstract:

A counter top beer dispensing tower structure including a thermo insulating jacket structure with a top wall, a flat counter top engaging bottom wall, rear and side walls, a flat vertically and laterally extending front wall and a body insulating material at the inner surfaces of the walls, a metal cold plate within the body of insulating material, a plurality of laterally spaced dispensing valve mounting parts carried by and projecting forwardly from the plate and accessible at the front wall, a plurality of elongate tubular beer conducting coils in the plate, each beer conducting coil has a downstream end portion connected with a related valve mounting part and a vertical upstream end portion depending from the plate and bottom wall to extend through a primary opening in a related counter and to connect with the downstream end on of related beer conducting line, and elongate tubular glycol coil unit within the plate and having vertical upstream and downstream end portions depending from the plate and the jacket structure to extend through the primary opening in the related counter and to connect with downstream and upstream ends of related delivery and return sections of an elongate glycol conducting lines a glycol chiller and, plurality of spaced apart elongate vertically extending threaded mounting studs anchored to and depending from tower jacket structure to extend through secondary openings in the related counter; and, nuts on the studs and engaging the counter to draw the bottom wall in to tight engagement with the top of the counter.

By Jay Brooks

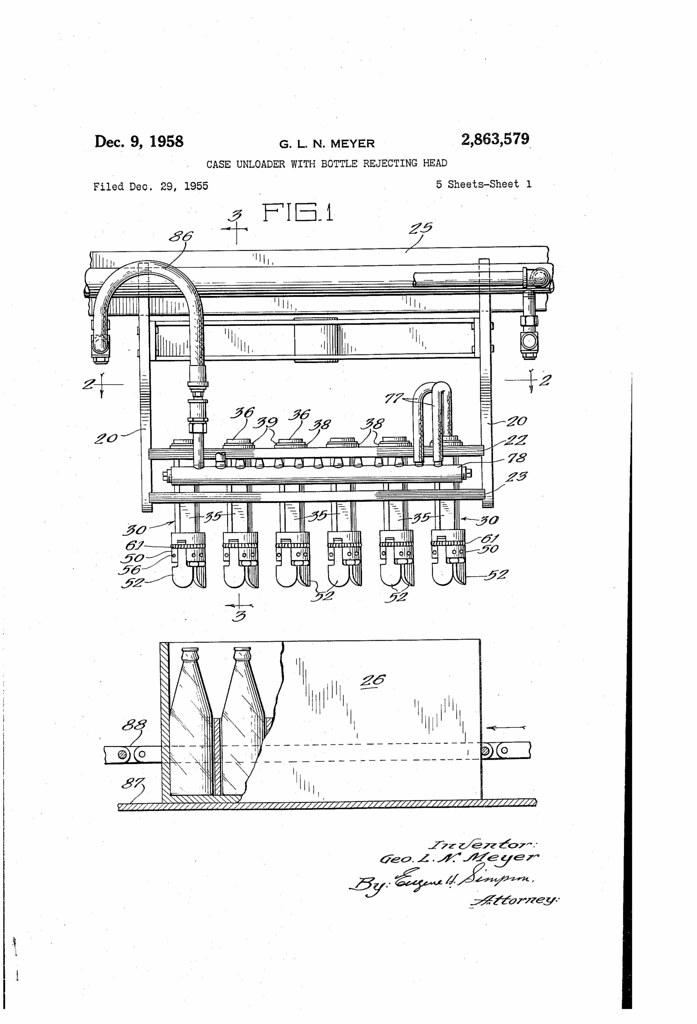

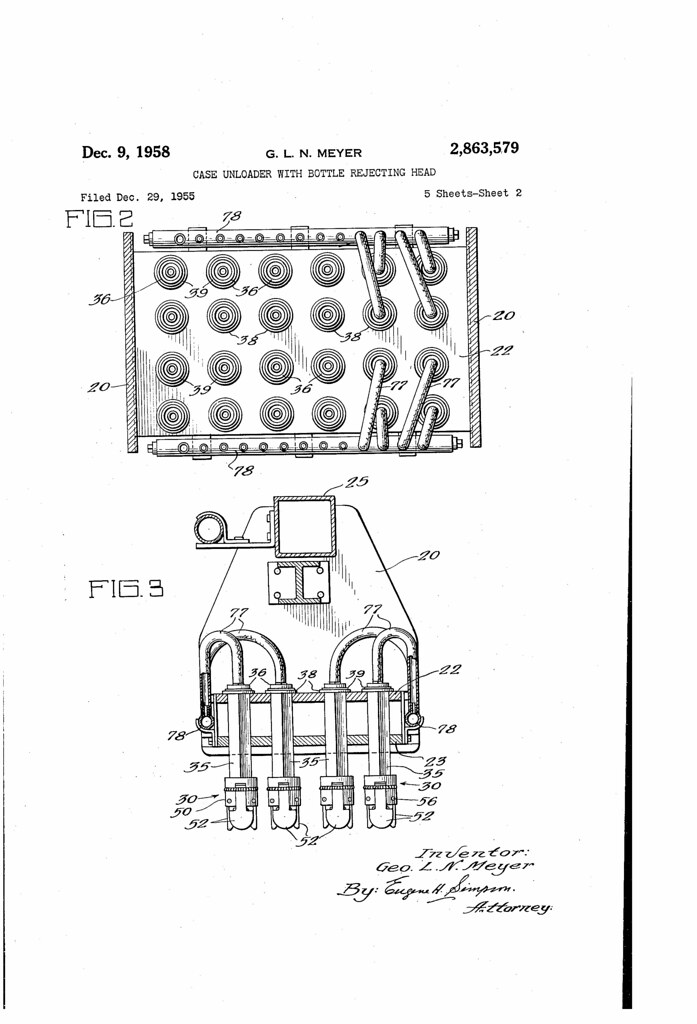

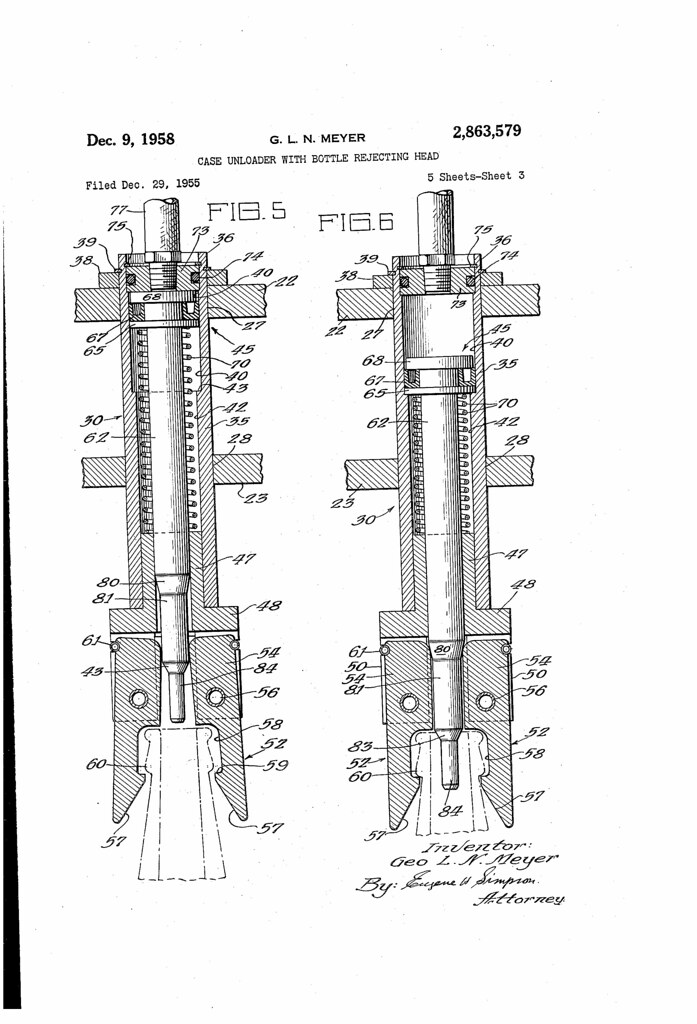

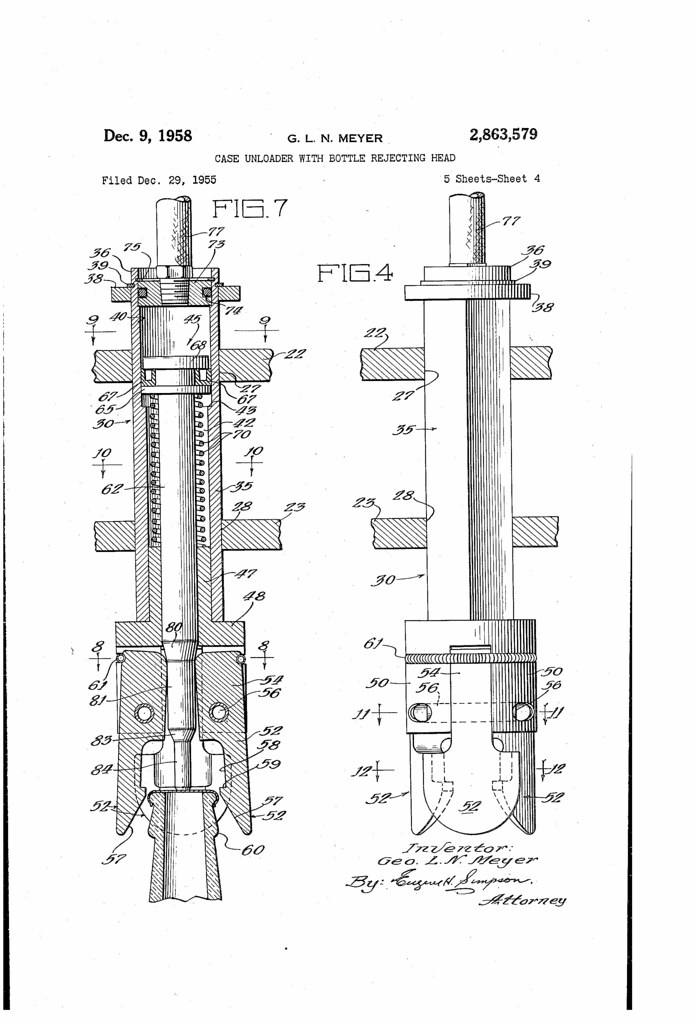

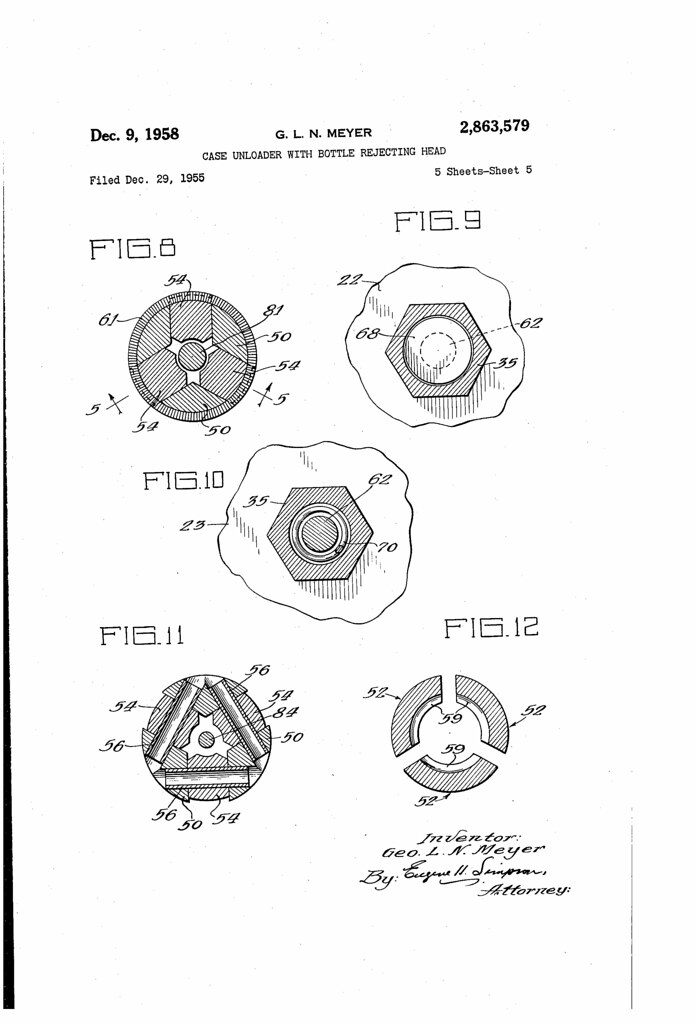

Today in 1958, US Patent 2863579 A was issued, an invention of George L.N. Meyer, for his “Case Unloader with Bottle Rejecting Head.” There’s no Abstract, although in the description it includes these claims:

This invention relates to a case unloader adapted to unload empty bottles from a case and to reject bottles with corks, caps or other obstructions in the neck of the bottle.

In case unloaders used to remove empty beer, carbonated beverage bottles, etc., from cases and deliver them to a bottle washer, or the like, prior to refilling, much trouble has been experienced with bottles that have been re-capped or which have a cork or other obstruction in the neck. Case unloaders heretofore made had no provision for rejecting such bottles and as a result bottles with caps or corks on the necks were processed through the bottle washer. When such bottles reached the inside brush station, or the rinsing station, the brush spindle, or the rinse nozzle, would strike the cap, cork or other obstruction and bend either the spindle or the nozzle, necessitating stopping of the machine to replace the damaged element.

It is an object of the present invention to provide a case unloader for bottles which will reject any bottles having a crown, cork or other such obstruction in the neck, and so prevent such bottles from going through the washing machine.

Another object is to provide a case unloader which will remove only those bottles from the case which have the necks of the bottles free of obstructions.

A further object of the invention is to provide a case unloader for beverage bottles, or the like, which will reduce break-downs in the bottle washing machinery.

A still further object is to provide a case unloader which will reduce the amount of supervision required to load bottles onto a bottle washer.

A still further object of the invention is to reduce the overall cost of washing bottles.

By Jay Brooks

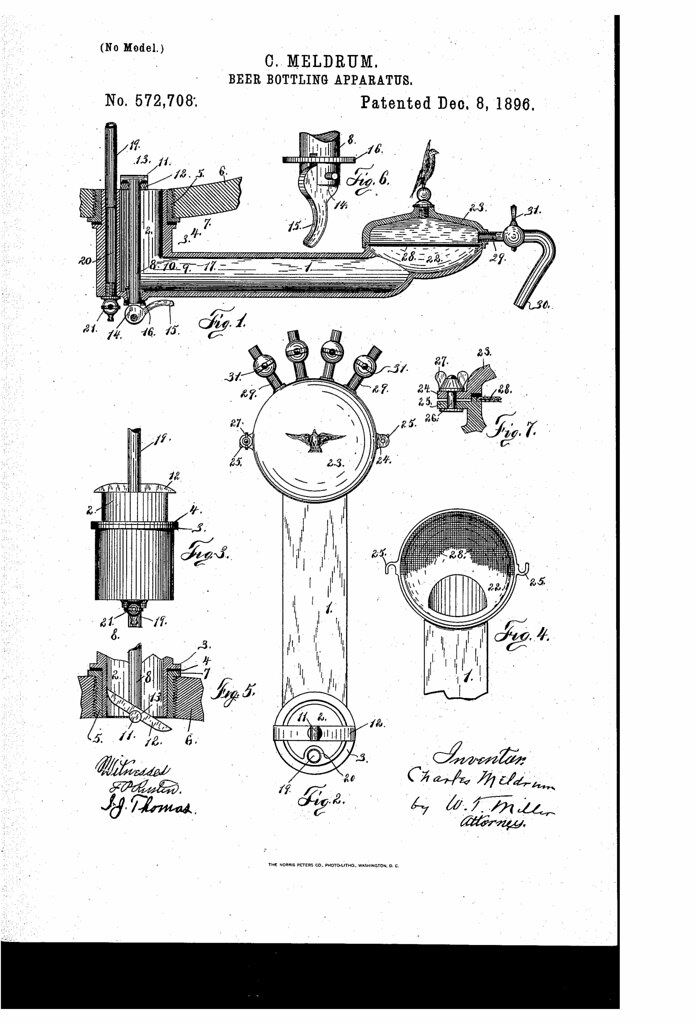

Today in 1896, US Patent 572708 A was issued, an invention of Charles Meldrum, for his “Beer Bottling Apparatus.” There’s no Abstract, although in the description it includes these claims:

Prior to my invention it has been the usual custom to fill bottles with beer from the keg by employing flexible rubber tubes which are passed down through the open bung-hole into the beer and siphoning the beer through these tubes into the bottles. The disadvantages in bottling beer in this manner are that too much air is admitted through the open bung-hole and the beer is subjected to unnecessary agitation in being siphoned over, all of which results in the liberation and escape of sufficient gas to materially effect the life of the beer. Then, too, any sediment or impurities which may be present in the beer in the keg are carried over into the bottles, which is also a serious objection.

-The object of my present invention is to overcome these defects in a simple and effective manner; and to that end it consists of a passage or conductor one end of which is adapted for tight insertion and removable retention in the bung-hole on the lower side of the keg and provided with a vent-tube which passes up through the beer and into the air-space above, the other end having a chamber across which is placed a strainer and a series of outlet-passages arranged in the wall of the straining-chamber and adapted for engagement with a series of flexible tubes, through which the strained beer passes by gravity into the bottles.

By Jay Brooks

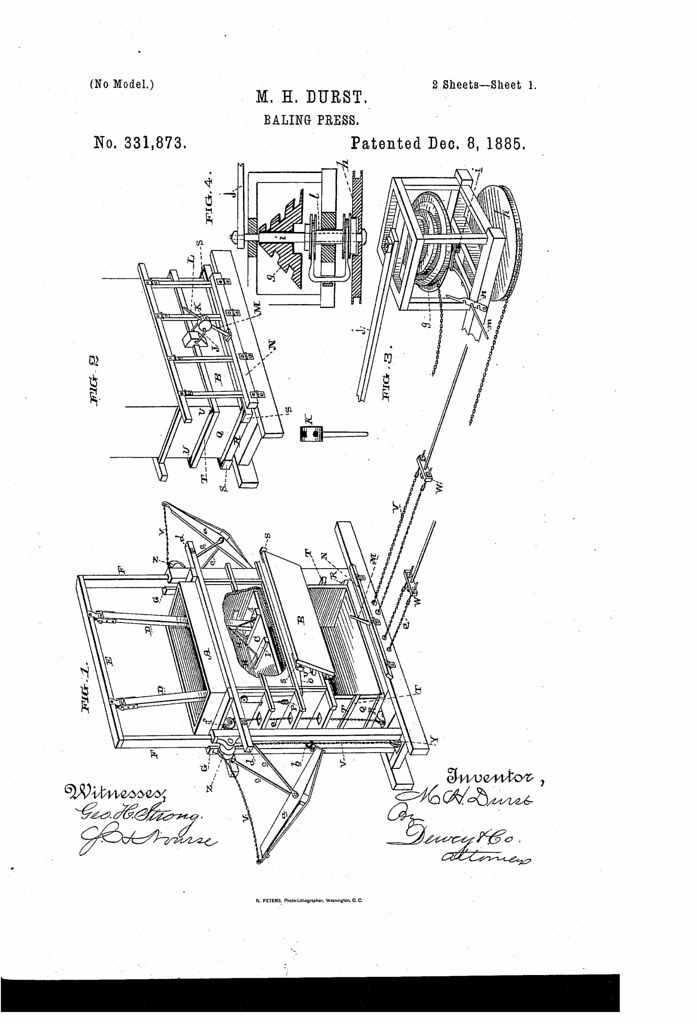

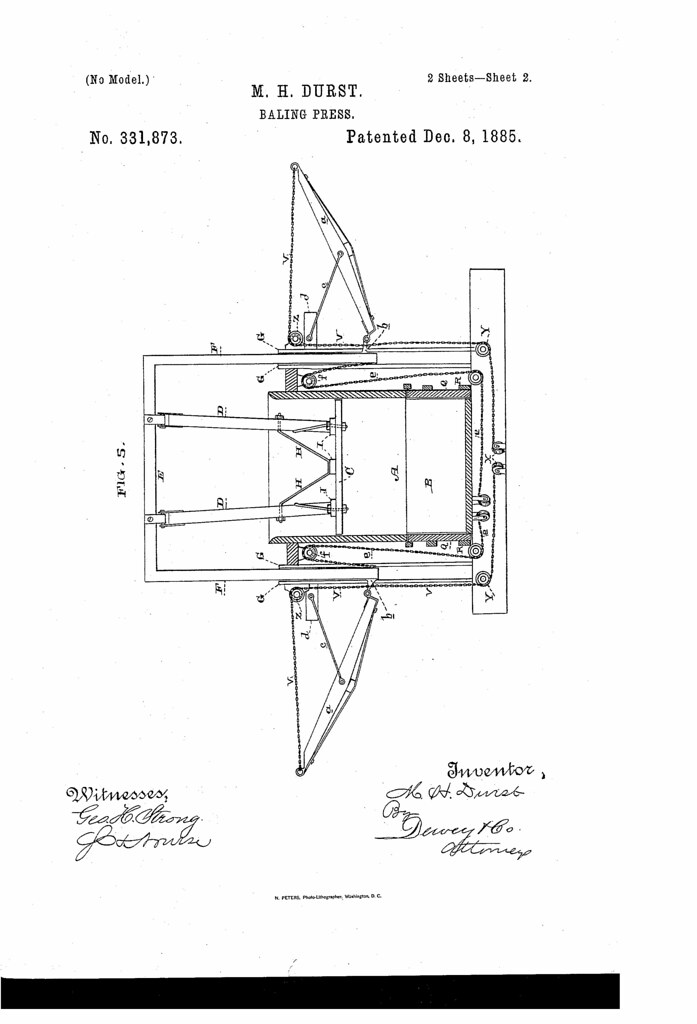

Today in 1885, US Patent 331873 A was issued, an invention of Murray H. Durst, for his “Baling Press.” There’s no Abstract, although in the description it includes these claims:

My invention relates to certain improvements in balling-presses; and it consists in certain details of construction, power, and means of application, all of which will be more fully described by reference to the accompanying drawings, in which- Figure 1 is a general view of the press. Fig. 2 shows the lower part of the press with the door closed. Fig. 3 is a view of the mechanism for raising and lowering the follower. Fig. 4 is a section of the same. Fig. 5 is a vertical section of the press.

This press is especially designed for the pressing of hops, and is preferably so built that the upper end of the vertical case or box A will be on a level with or under the floor upon which the hops are contained, while the lower end, having discharge-doors B, communicates with the floor below. The follower C fits the press-box A, and has arms D extend ing Vertically upward from it and hinged to a crossbar, E, the ends of which are strongly secured to the vertical timbers F. These timbers move in vertical guides G, as shown, and when drawn down will force the follower down to the bottom of the press-box, and when raised will elevate it, so that when it arrives at a point just above the top of the box and the level of the floor with which it communicates the follower will be swung to one side about the hinges by which its supporting-timbers D are connected with the transverse bar E, before described.

By Jay Brooks

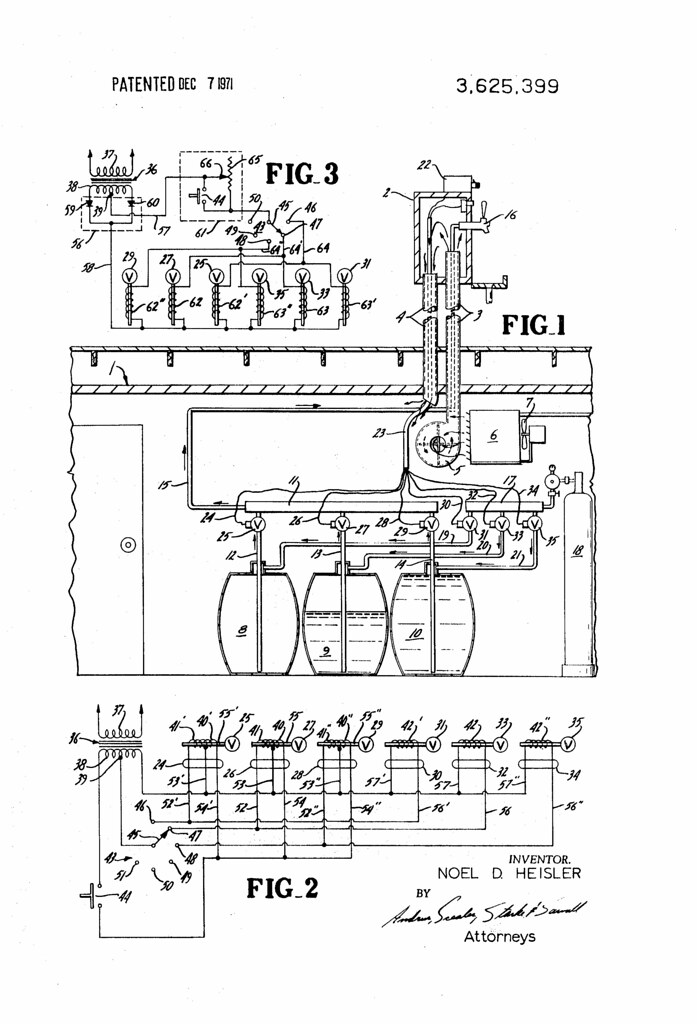

Today in 1971, US Patent 3625399 A was issued, an invention of Noel D. Heisler, assigned to the Schlitz Brewing Co., for his “Automatic Carbonated Beverage Dispensing System.” There’s no Abstract, although in the description it includes these claims:

In general, the invention is directed to an electrical release or dispensing system for a plurality of carbonated beverages stored in suitable containers where it is desirable at a remote distance therefrom to initiate the dispensing of the beverages from another and successive container when the container from which the beverage being dispensed is empty. The system provides a header which is connected to the containers to be emptied by separated conduits in which are located solenoid liquid valves. These valves are separately actuated from a selector control unit to open a respective conduit from a container to the header and then to to a tap. A second header is connected to a source of Co gas and flow of gas from the header to the containers are through separate conduits to each container. Solenoid fluid valves are located in each gas conduit and are individually actuated to control the flow of gas to the container being tapped. The opening of a respective fluid solenoid valve occurs simultaneously with the opening of a corresponding liquid valve An important feature of the invention is that the dispensing valves are opened by momentary high surge of current to seize the solenoid armature and are held in the open position by a low holding current. The holding current consumes less power and consequently gives off less heat. In an alternative construction, the liquid dispensing valves may each be dual winding units having an opening winding and a holding winding. The holding winding draws a lesser current and consequently also minimizes generation of heat. Excessive heat is deleterious to the carbonate beverage being dispensed.