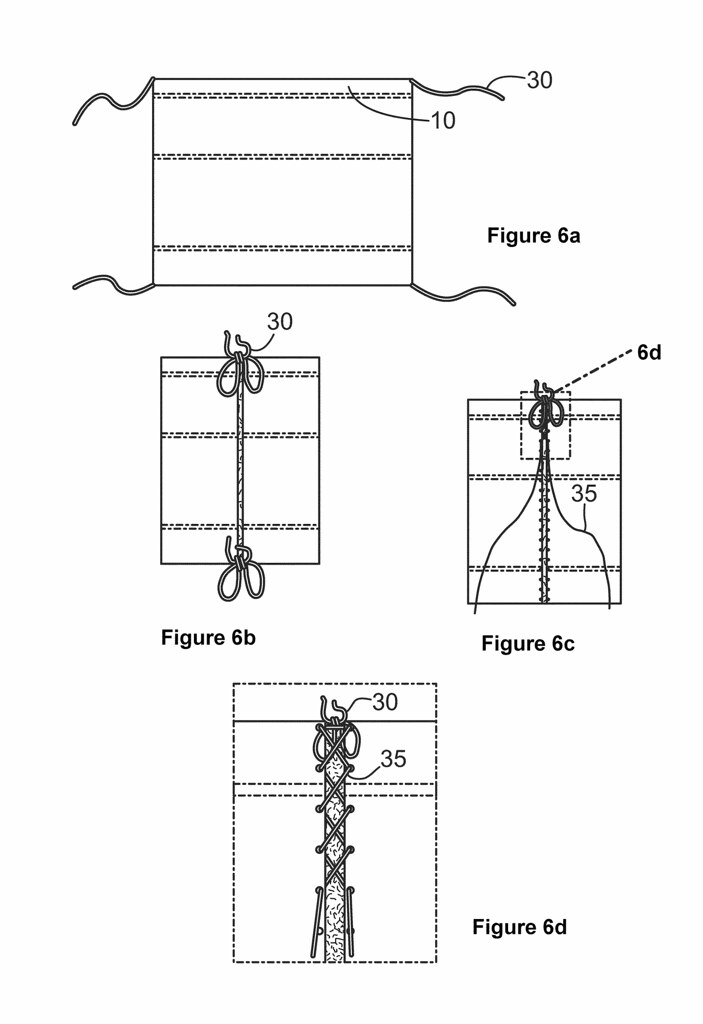

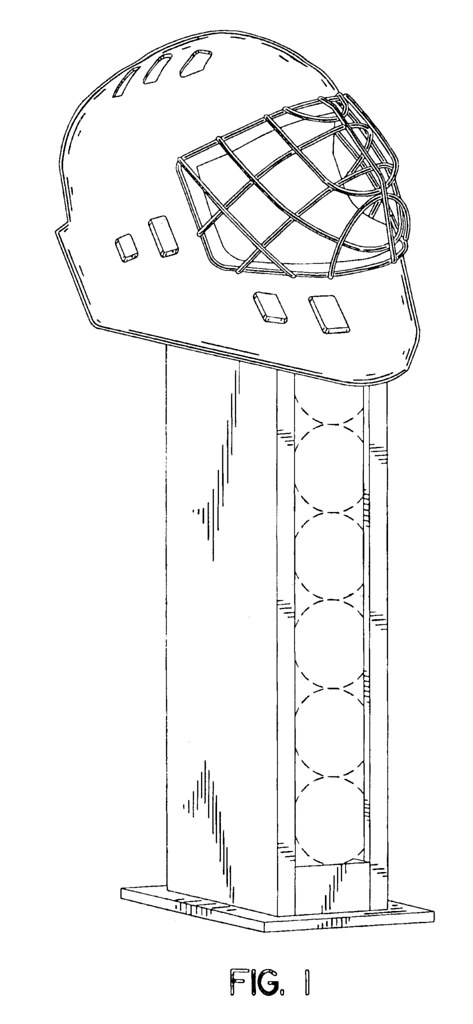

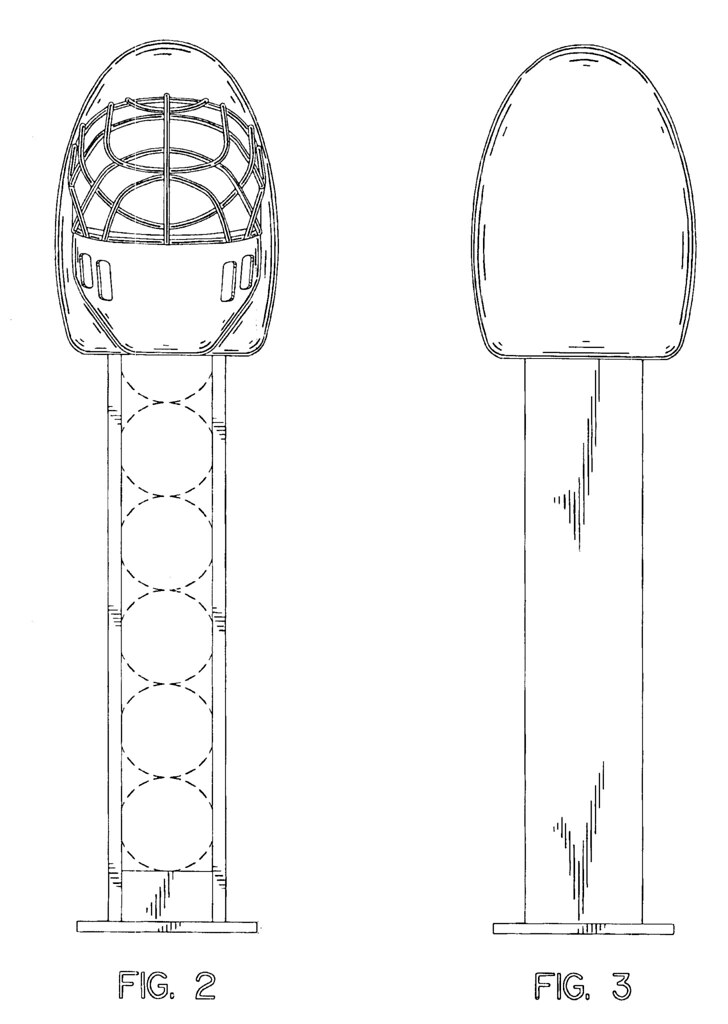

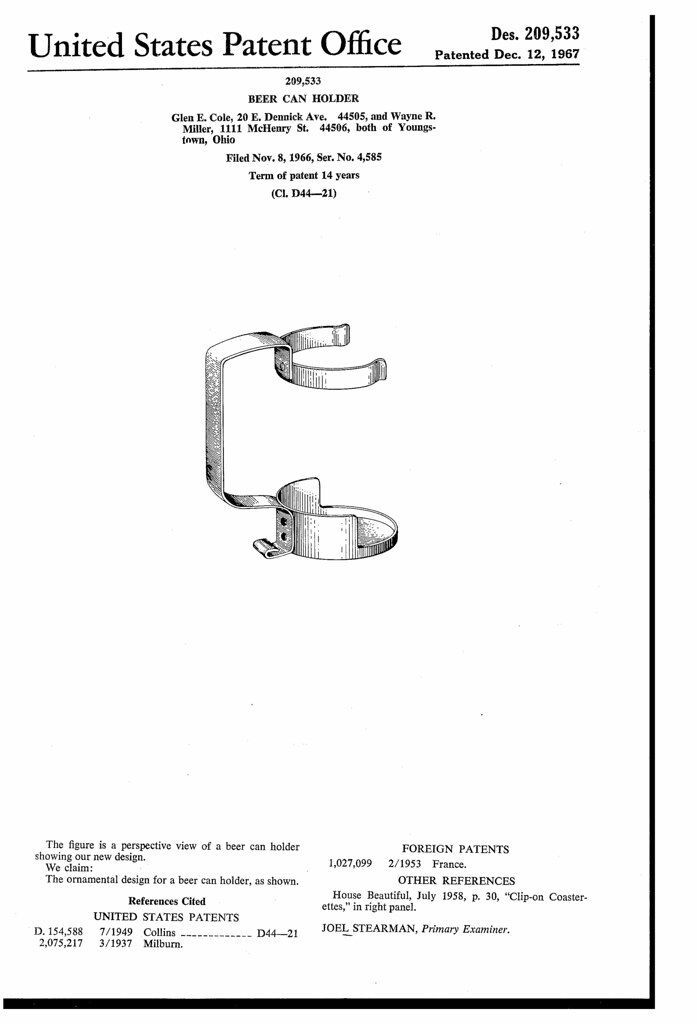

Today in 2006, US Patent D533739 S1 was issued, an invention of Brian Miesieski, Devin Kelly, and Geoff Blanck, assigned to the Labatt Brewing Company Limited, for their “Goalie Mask Beer Dispenser.” There’s no Abstract, although this is the entire claim:

The ornamental design for a goalie mask beer dispenser, as shown and described.

>

>