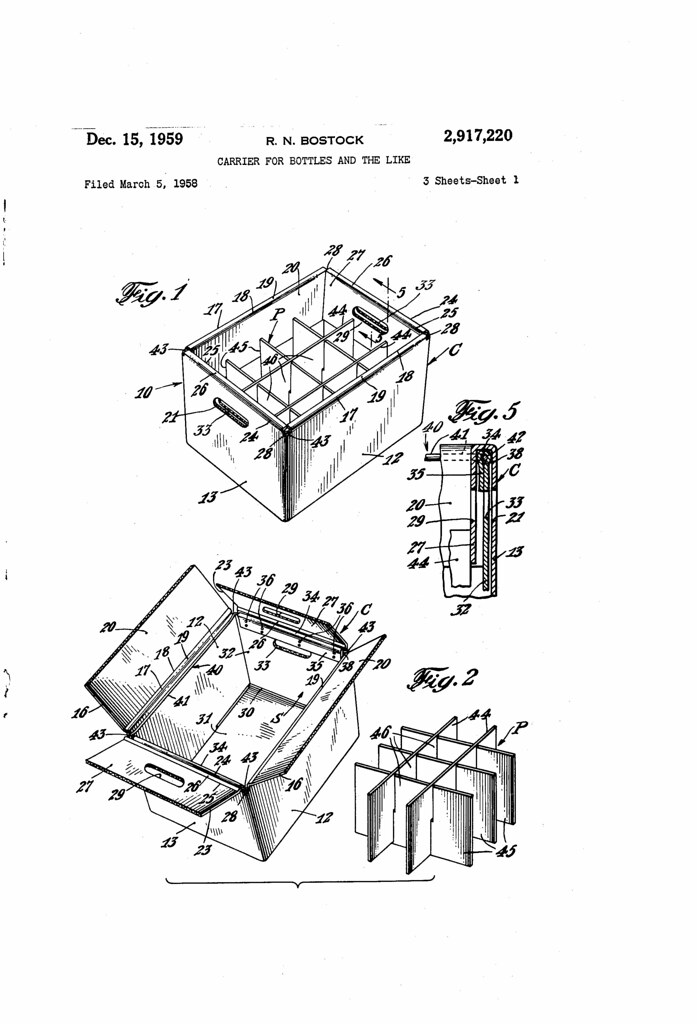

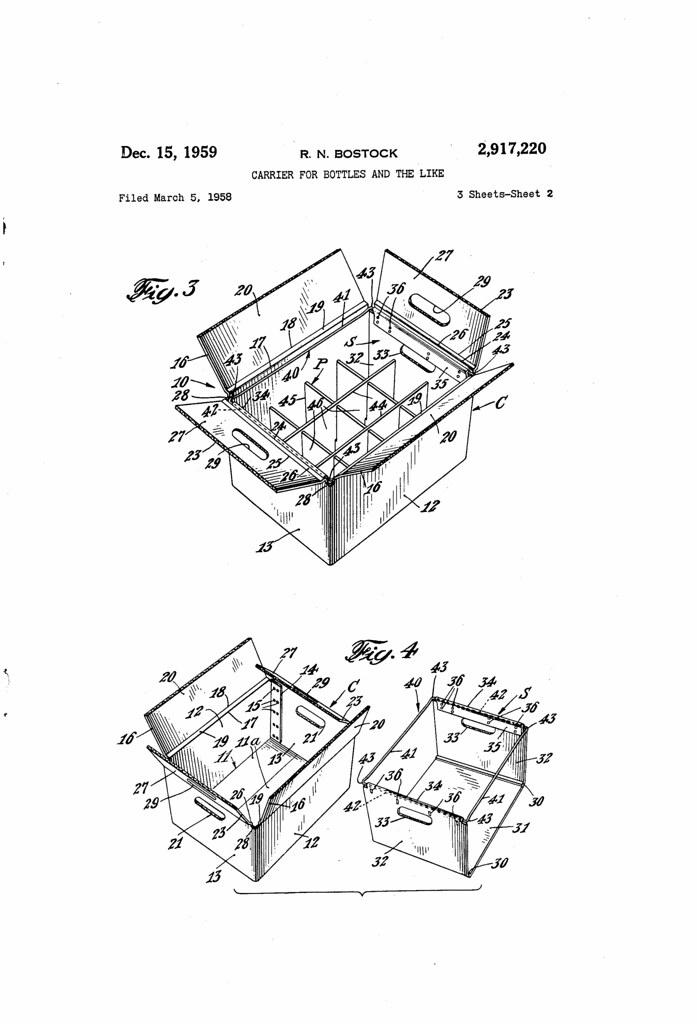

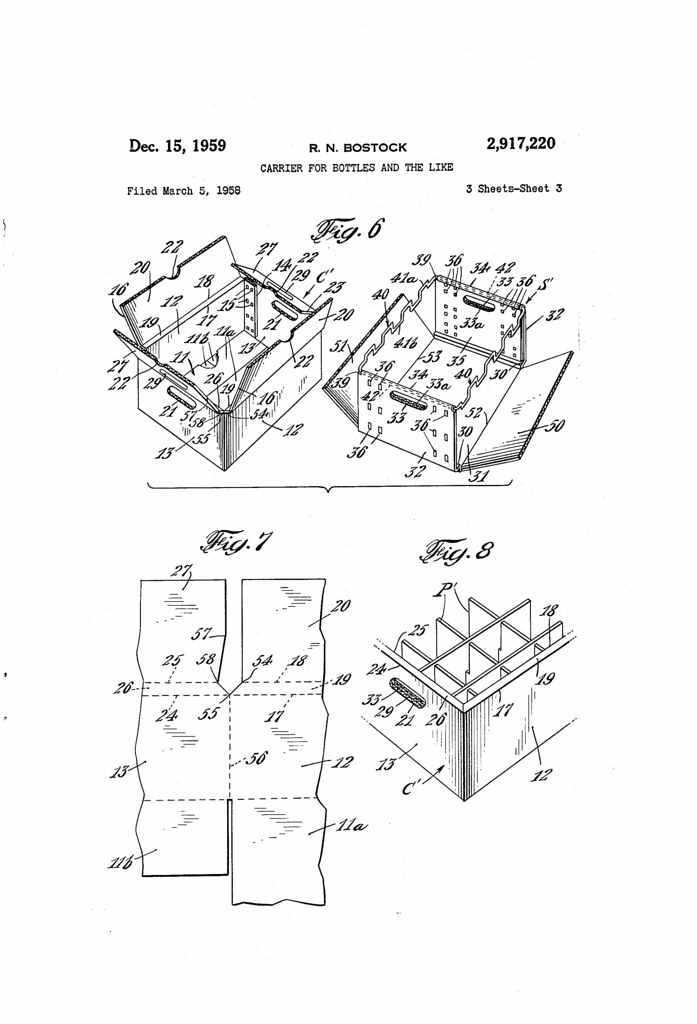

Today in 1959, US Patent 2917220 A was issued, an invention of Raymond N. Bostock, assigned to Ballantine & Sons, for his “Carrier for Beer Bottles and the Like.” There’s no Abstract, although in the description it includes these claims:

Open top cartons, that is cartons having bottom, side and end Walls, but not a top wall or cover, have been used for a number of years for the purpose of storing and transporting Various items of merchandise, including glass bottles containing beer, soft drinks or other liquids. Such cartons are usually provided with partitions that divide their interiors into compartments for receiving individual bottles to prevent the bottles from coming into direct contact with each other, thereby minimizing the possibility of breakage of the bottles in the course of handling.

Due to the weight of the merchandise and the rough handling to which loaded cartons are frequently subjected, present-day open cartons are generally constructed of heavy fibreboard. It is often necessary, in order to provide adequate strength and rigidity, to reinforce the cartons in various ways. As a consequence, such cartons are quite expensive.

container may be made of a relatively lightweight, inexpensive corrugated cardboard. The sling is preferably made of a heavy duty fibreboard, while the partition unit is made of a suitable grade and Weight of fibreboard. Fibreboard is recommended for the sling and partition unit, to provide necessary strength and to permit repeated reuse of the same, with the initial or subsequent outer containers. Also, the sling and partition unit are treated to make them waterproof, thereby protecting them from moisture and prolonging their useful life. It will be understood that the term paperboard, as used hereinafter and in the appended claims, is intended to cover various sheet materials that may be used in the mantufacture of the carrier of this invention, whether corrugated cardboard, fibreboard or other appropriate material.

The primary object of the invention is to provide a carrier for bottles or the like having improved features’ of construction.

Another object of the invention is to provide a bottle carrier having a relatively inexpensive disposable outer container.

Another object of the invention is to provide a bottle carrier having a relatively inexpensive outer container, which may be discarded when scuffed or otherwise rendered unsightly, and a relatively strong reinforced inner container, which may be reused many times with successive outer containers.