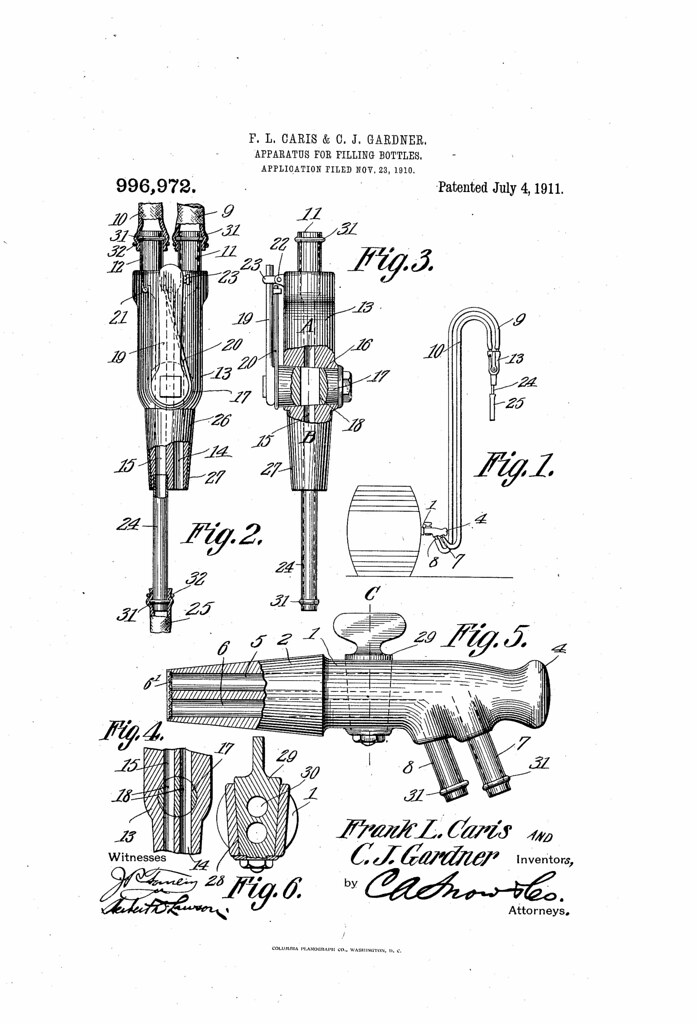

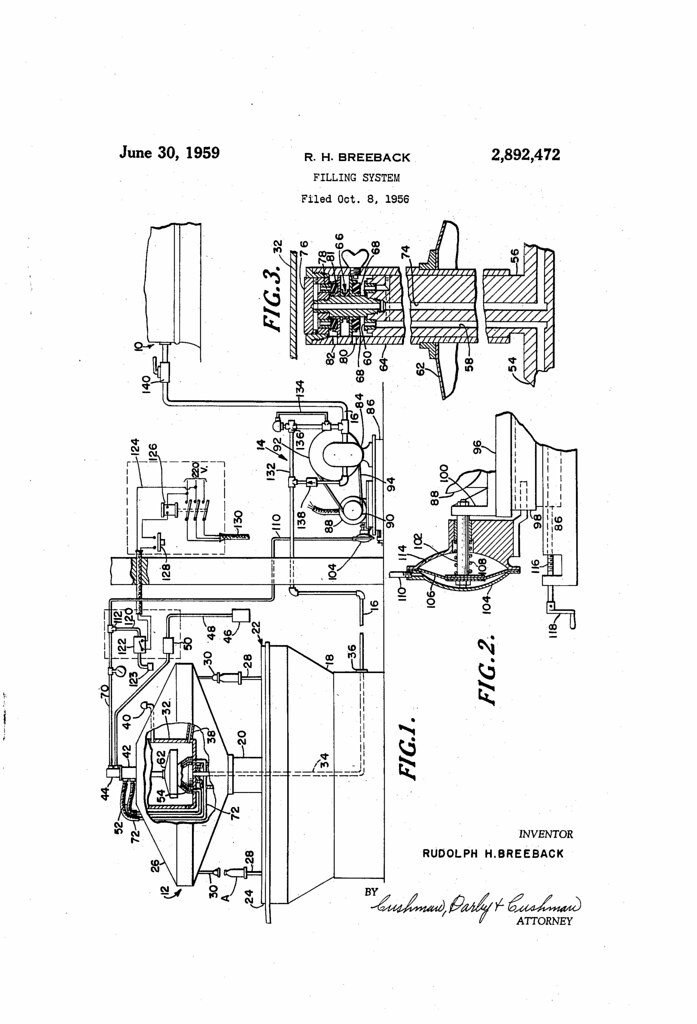

Today in 1911, US Patent 996972 A was issued, an invention of Frank L. Caris and Clarence J. Gardner, for their “Apparatus For Filling Bottles.” There’s no Abstract, although in the description it includes this summary:

This invention relates to apparatus for use in filling bottles from kegs or barrels, the same being particularly adapted for bottling beer and the like.

One of the objects of the invention is to provide an inexpensive device of this character which can be readily handled by one person, there being improved means for discharging the liquid into the bottle and for permitting the escape of foam back to the keg or other receptacle from which the liquid is drawn.

A further object is to provide apparatus of this type having a nozzle in which is mounted a valve normally maintained in closed position but which can be conveniently held open during the filling operation. With the foregoing and other objects in view, the invention consists in the combination and arrangement of parts and in the details of construction hereinafter described and claimed, it being understood that changes in the precise embodiment of invention herein disclosed can be made within the scope of what is claimed, without departing from the spirit of the invention.