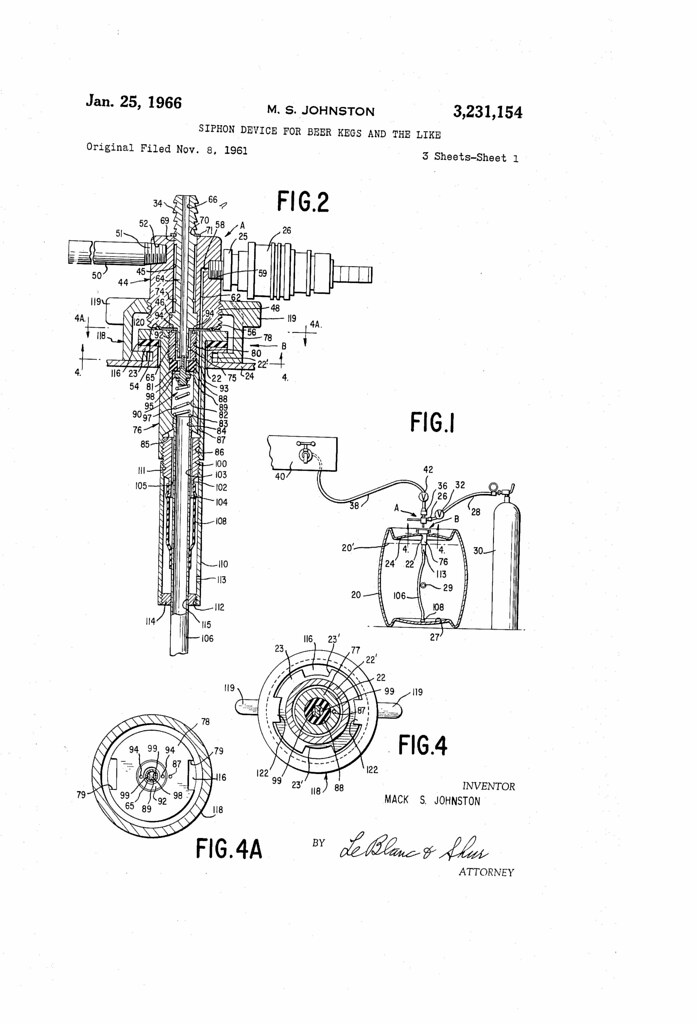

Today in 1966, US Patent 3231154 A was issued, an invention of Mack S. Johnston, for his “Siphon Device For Beer Kegs and the Like.” There’s no Abstract, although in the description it includes this summary:

The present invention relates to a new improved gas pressure siphon device for drawing fluid such as beer from containers such as beer kegs or barrels, using a gas to drive” the fluid from the container. More especially, the present invention relates to a new improved siphon device comprising a portion which remains in the keg at all times, whereby the keg is constantly sealed, and another portion which is permanently connected to a dispenser (as in a restaurant) and can be readily connected to’ the keg portion by a bar tender so that the dispensing siphon is automatically in operating condition.