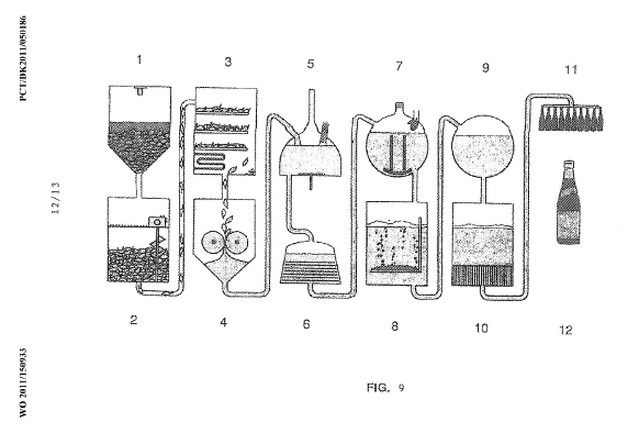

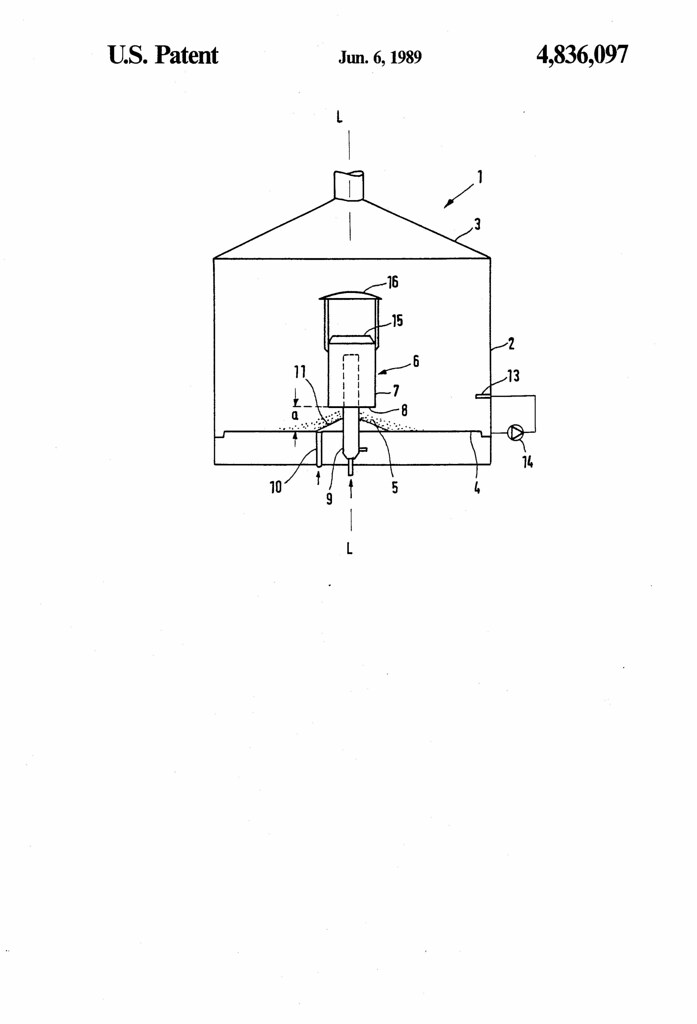

Today in 2010, US Patent 7730912 B2 was issued, an invention of John Richard Blichmann, for his “Bottle Filler.” Here’s the Abstract:

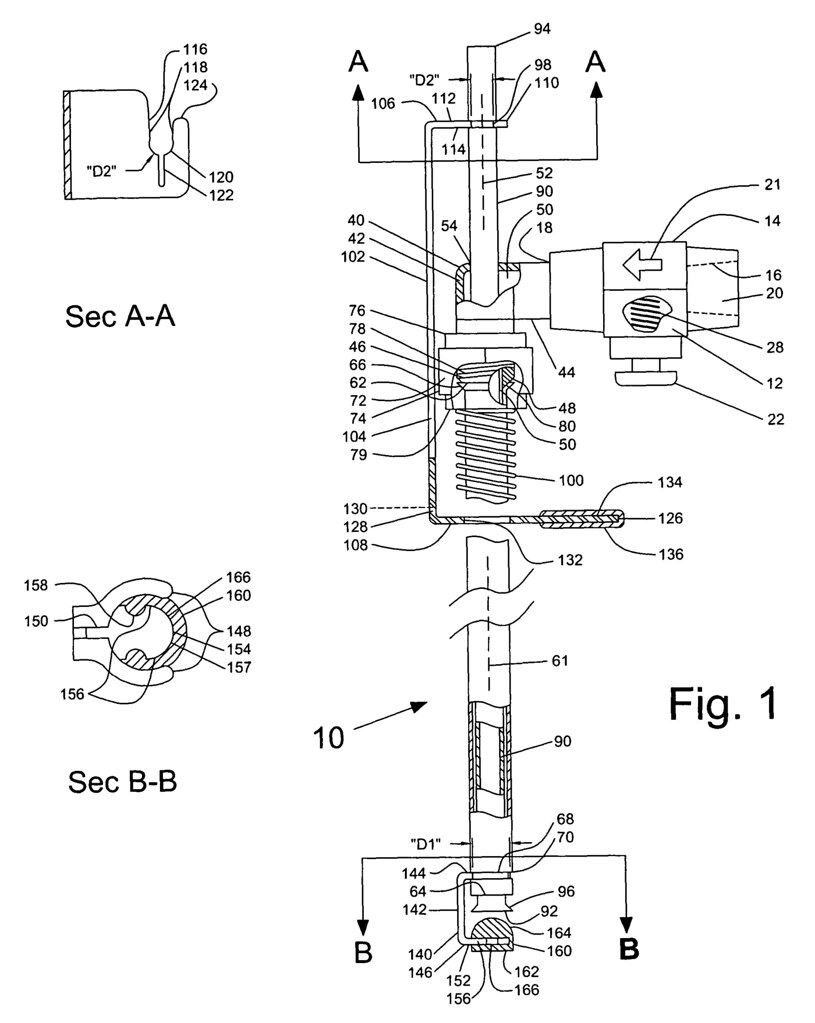

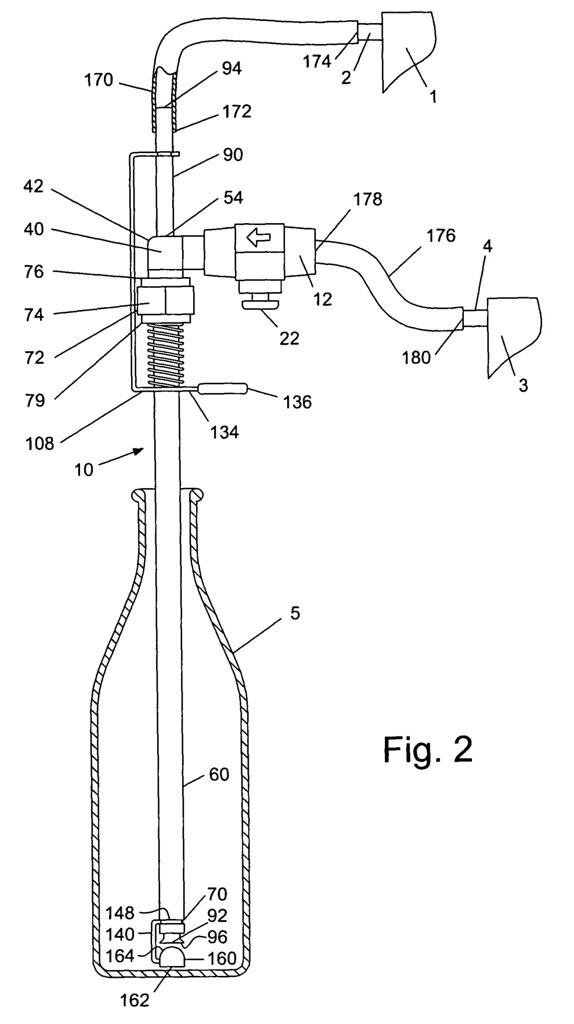

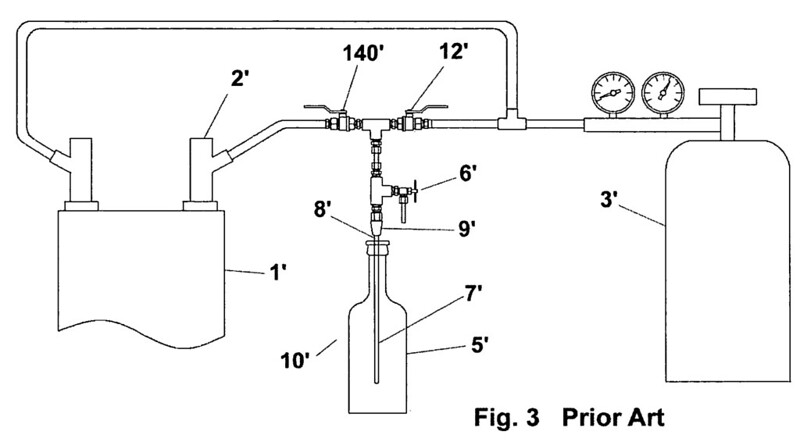

An improved bottle filler assembly for filling bottles from kegged carbonated or non carbonated beverages without carbonation loss or oxidation that is intuitive to use, sanitize, and keep free of bacteria. In the preferred embodiment, a long hose gradually reduces the pressure of the beverage on the way to the filler. Two tubes are placed inside each other forming an annulus where CO2 can be forced to the bottom of the bottle via a CO2 valve thereby purging the bottle of air (O2). A valve seat placed on the bottom of the tubes allows the beverage to flow into the bottle from the bottom by depressing a trigger.