Today in 1965, US Patent 3171746 A was issued, an invention of David Teignmouth Shore, for his “Production of Brewers’ Wort.” There’s no Abstract, but in the description Shore explains that his “invention relates to the production of brewers wort at the mashing stage in which a reaction is created between water and goods, i.e., ground solids or grist to obtain as a product of the stage a wort which is known as sweet wort: the sweet Wort is passed on for further treatment including heating, hopping and fermentation treatment to produce beer of one grade or style or another.”

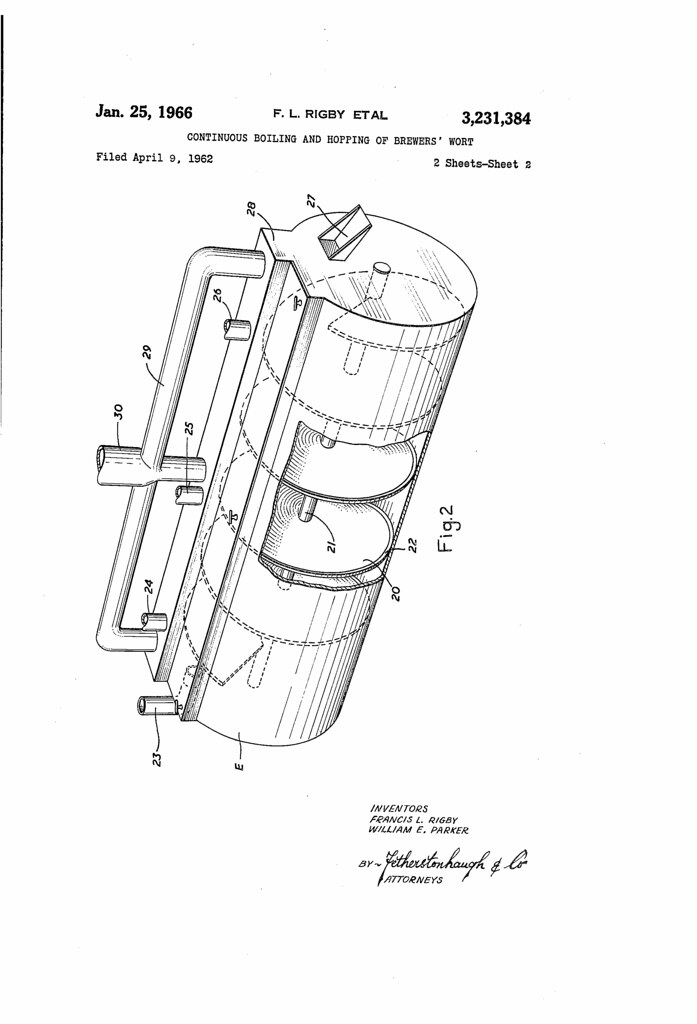

Patent No. 3231384A: Continuous Boiling And Hopping Of Brewers’ Wort

Today in 1966, US Patent 3231384 A was issued, an invention of William Ernest Parker and Francis Lloyd Rigby, assigned to Canadian Breweries Ltd., for their “Continuous Boiling and Hopping of Brewers’ Wort.” There’s no Abstract, but partway down in the description is this:

The method of the present invention generally comprises forming a continuously flowing stream of hot brewers wort, causing said stream to flow in a substantially horizontal path, continuously introducing a predetermined mass of hops to said stream, heating said flowing wort, venting said stream of undesirable volatiles above said path of flow and controlling the time flow ratio of said wort and hops as to hop said wort to desired degree, and finally continuously discharging spent and hopped wort from said stream. This may be carried out with the wort and hops flowing counter-current to one another, discharging spent hops at one end of the path and hopped wort at the other. Alternatively, it may be carried out in a co-current flow.

The method may be carried out in particularly simple apparatus which may take the form, for counter-current flow, of a substantially horizontally disposed tubular vessel with provision for introducing wort towards one end thereof and hops in the other end thereof and which includes a perforated auger moving the hops in countercurrent flow to the continuously flowing wort as to cause spent hops to discharge at one end of the apparatus and hopped wort at the other, and which is a preferred type of apparatus proposed although such counter-current flow might be achieved by apparatus of other design. For cocurrent flow, the wort is introduced at one end while the hops are introduced adjacent that end and/or selectively along the length of the vessel.

Patent No. 718253A: Concentrated Hopped Wort And Process Of Producing Same

Today in 1903, US Patent 718253 A was issued, an invention of Herbert Amos Hobson of London, England, assigned to the Concentrated Beer Company Ltd., for his “Concentrated Hopped Wort and Process of Producing Same.” There’s no Abstract, or any drawings filed with the application, but here’s the introductory overview:

This invention relates to the production of a hopped wort from which beer, either alcoholic or non-alcoholic, maybe produced by the mere addition of yeast and water or of water alone, as the case may be.

In the ordinary brewing process the malt is first mashed and the hops are then added to and boiled in the wort or extract of malt, with the result that the bitter of the hop is unfavorably affected, objectionable resinous matters are extracted, and the volatile aroma of the hops is to a great extent lost, and these undesirable results are partly due to the length of time for which the boiling is continued and partly to the high boiling-point of the liquor in which the hops are boiled. It is the object of this invention to avoid these defects and to produce a hopped wort, preferably in a concentrated state, possessing the keeping qualities necessary for export purposes and adapted for the production, in the locality or country of consumption, of beer possessing the characteristic qualities of beer brewed in the ordinary manner.

While there weren’t any images in the filing, this is a flowchart of Alternative Sources of Hopped Wort from a homebrewing website in South Africa.