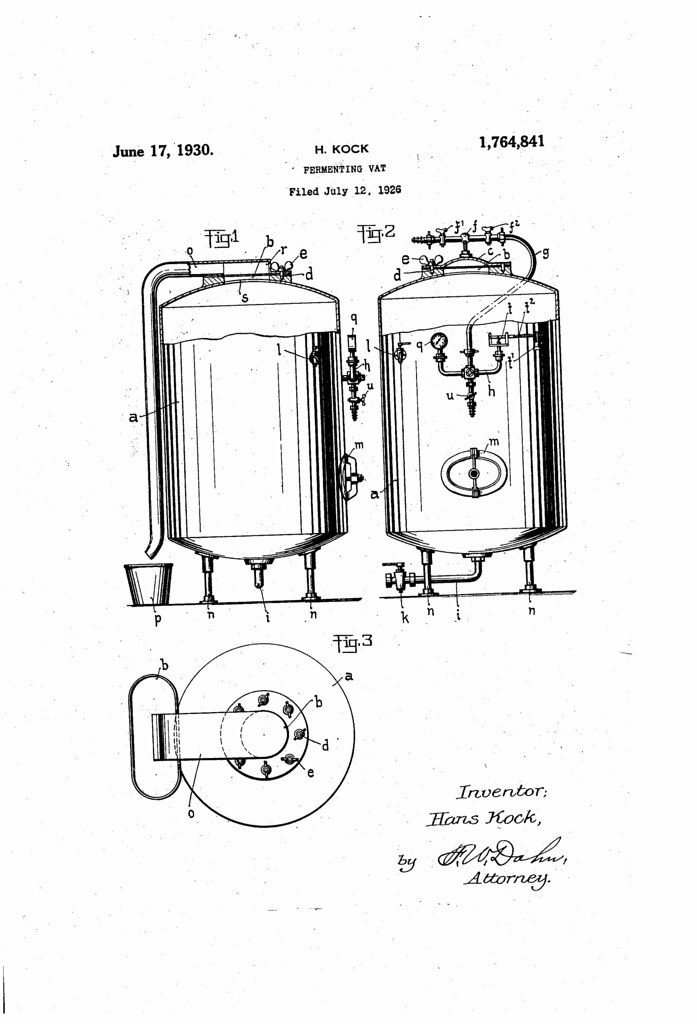

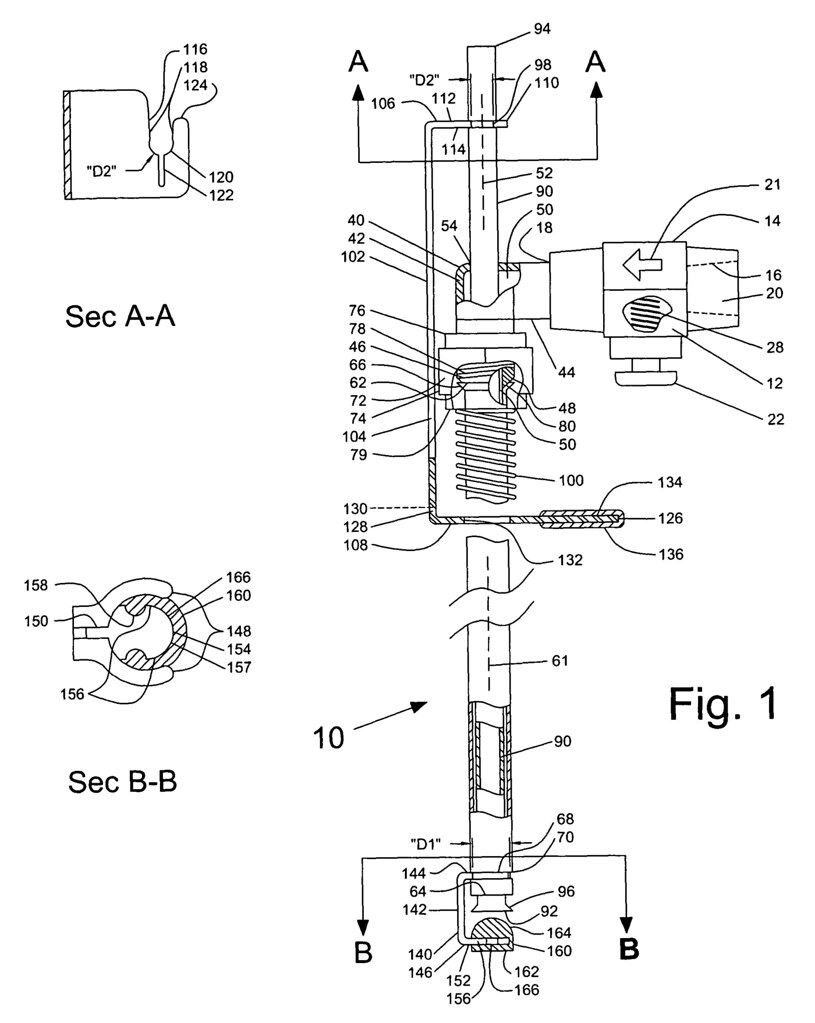

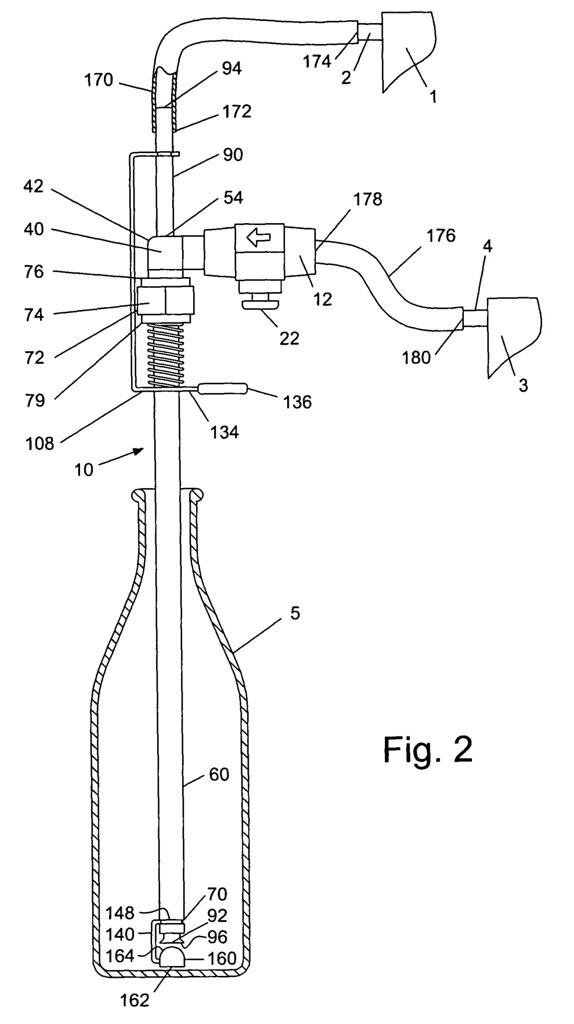

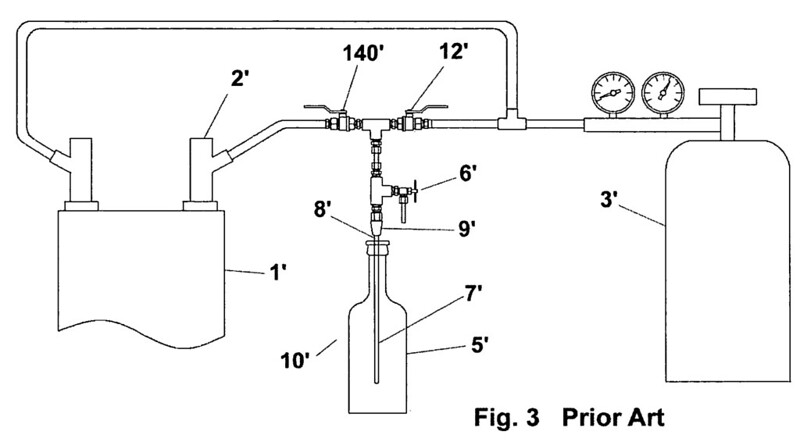

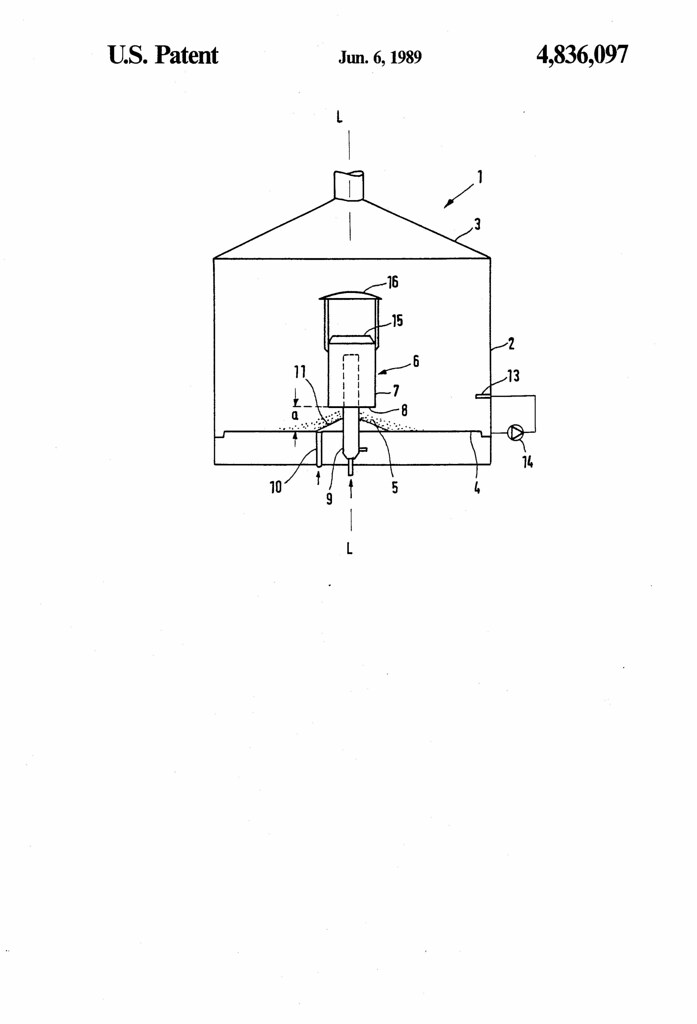

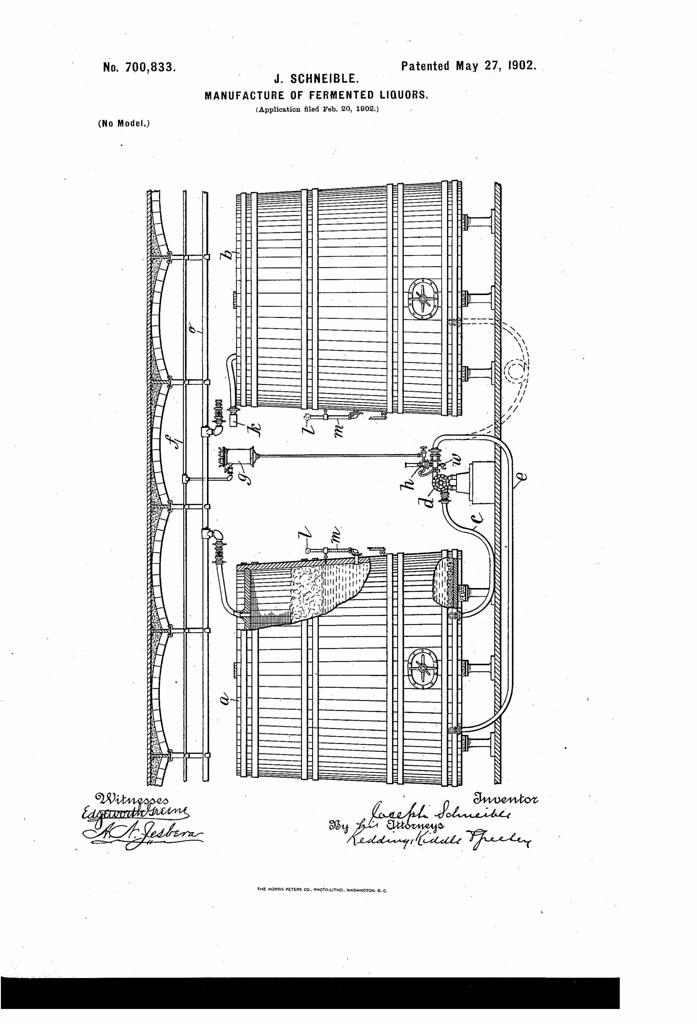

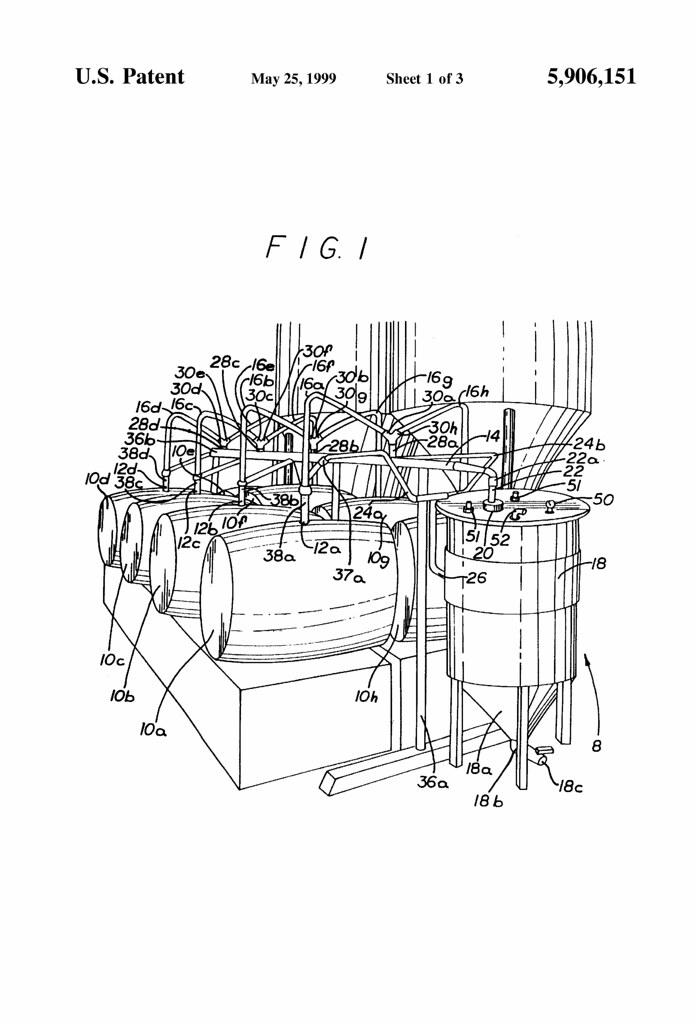

Today in 1930, US Patent 1764841 A was issued, an invention of Hans Kock, for his “Fermenting Vat.” There’s no Abstract, though it’s described this way in the application:

My. invention relates to improvements in fermenting vats, and the object of the improvements is to provide a vat which can be used for fermenting beer and other liquors, storing the beer and filling the same into hot ties. With this object in view my invention consists in forming the vat at its top with an opening adapted to have either one of the attachments necessary for fermenting the beer, storing the same and filling the same into bottles secured thereto, and constructing such attachments so that they can be readily mounted on and dismounted from the said vat.