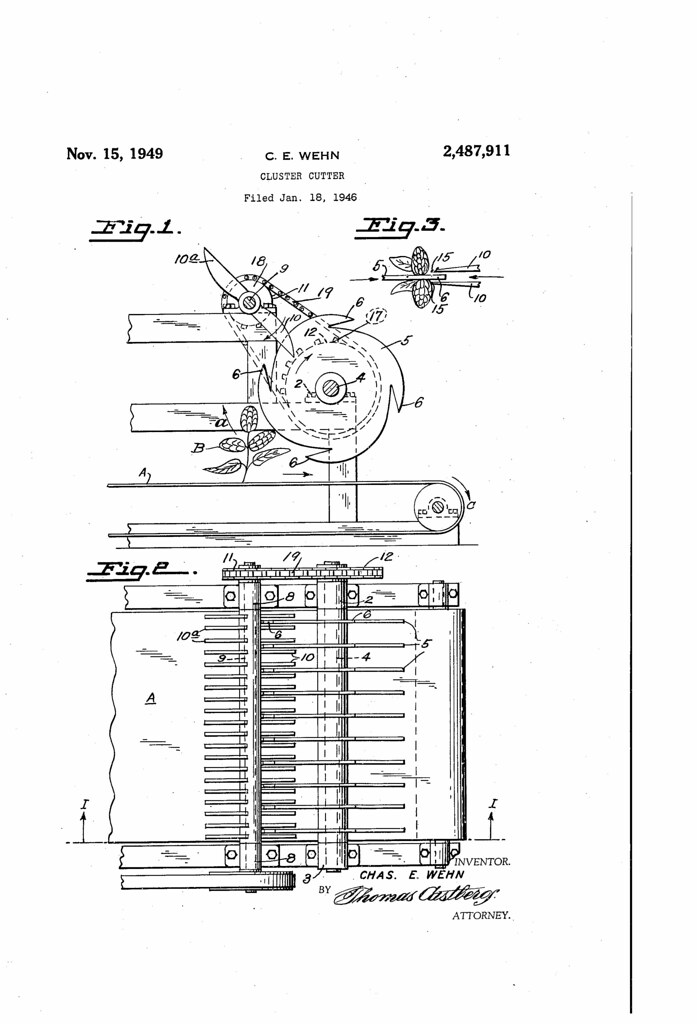

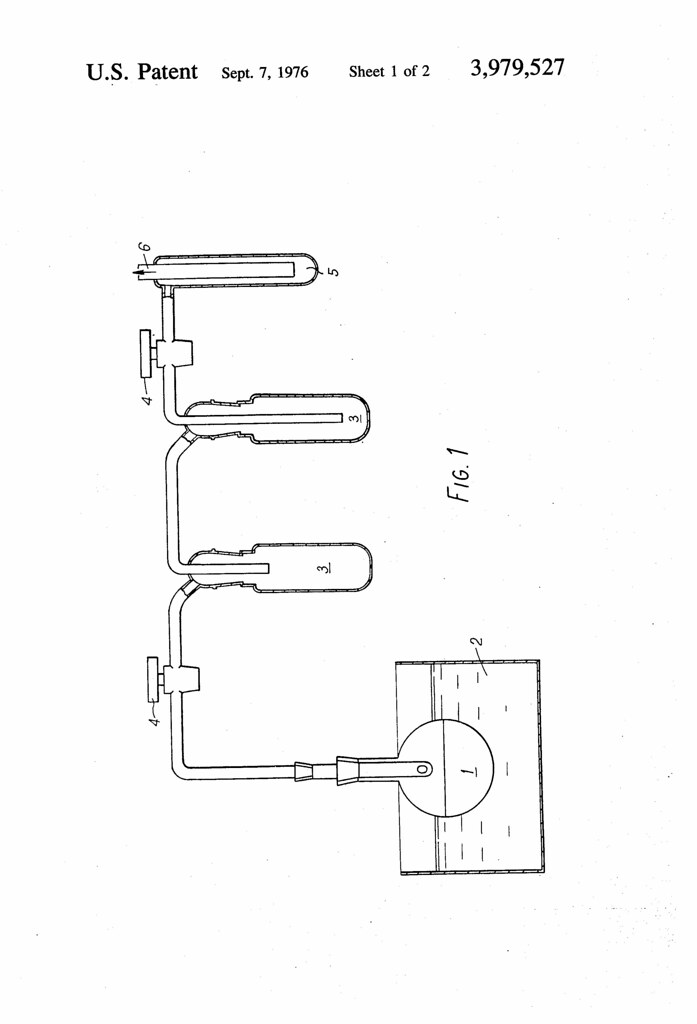

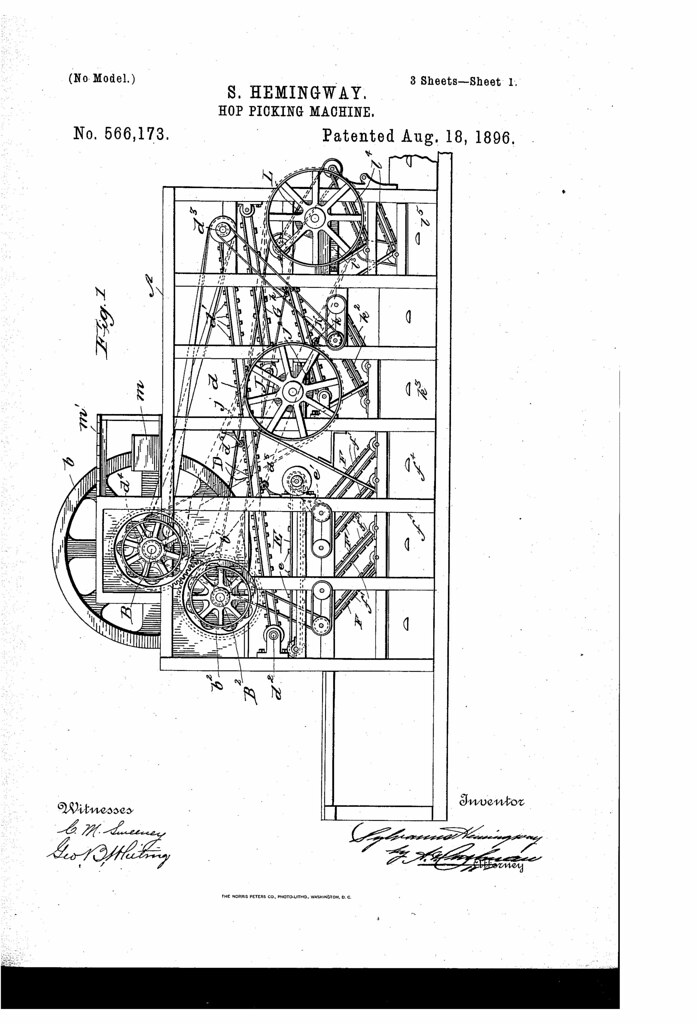

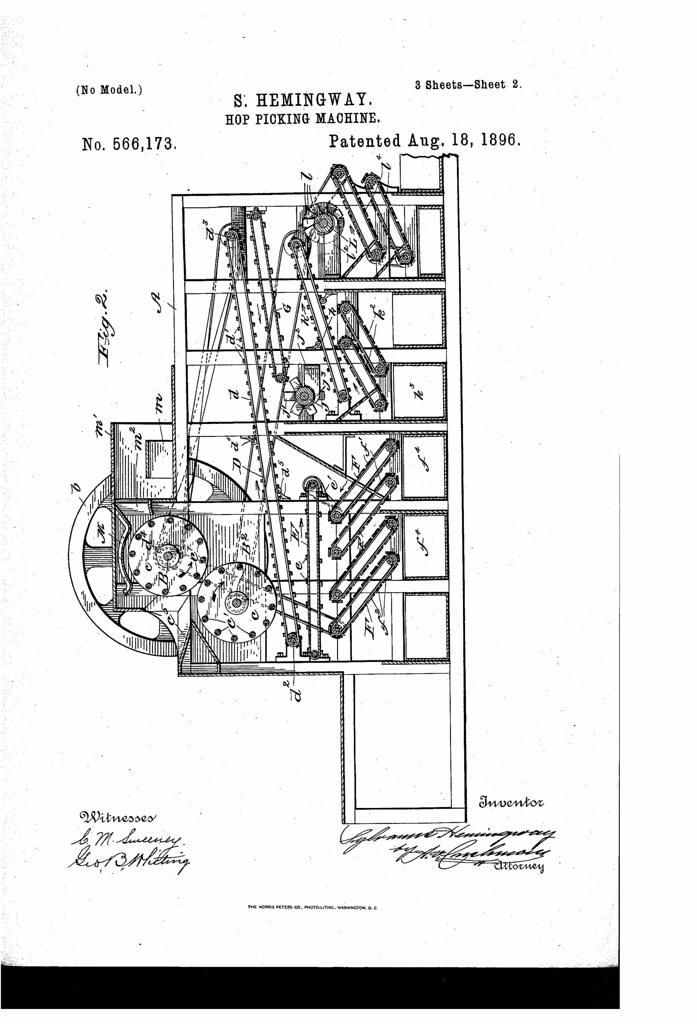

Today in 1949, US Patent 2487911 A was issued, an invention of Charles E. Wehn, for his “Cluster Cutter.” There’s no Abstract, although in the description it includes these claims:

The object of the present invention is to provide a machine whereby clusters of several hops may be quickly and readily separated. A gentle method would be to hold a cluster in the hand and with scissors clip the stems, so that leaves and hops would be separated. To circumvent such a tedious process, the present invention operates in a similar gentle manner. A hook on a revolving disc engages the stem of a cluster. As the hook raises the cluster, the hops settle to either” side of the disc and only the stem on the hook passes through the cutters, the hops falling away uninjured.