Today in 1969, US Patent 3438553 A was issued, an invention of Mack S. Johnston, for his “Tapping Device for Beer Kegs and the Like.” There’s no Abstract, but the description states the following. “This invention relates to a new and improved tapping device for drawing liquids such as beer from containers such as beer kegs or barrels, using a gas to drive the fluid from the container. In particular, the invention relates to a new improved tapping device usable with conventional beer kegs such as the so-called peerless and golden gate systems, and comprises a sub-unit called a keg adapter which constantly seals the keg, and another sub-unit called a coupler which it attached to the beer dispensing apparatus in a restaurant or tavern and is readily connected to the keg adapter so that the tapping device is automatically in operating condition.”

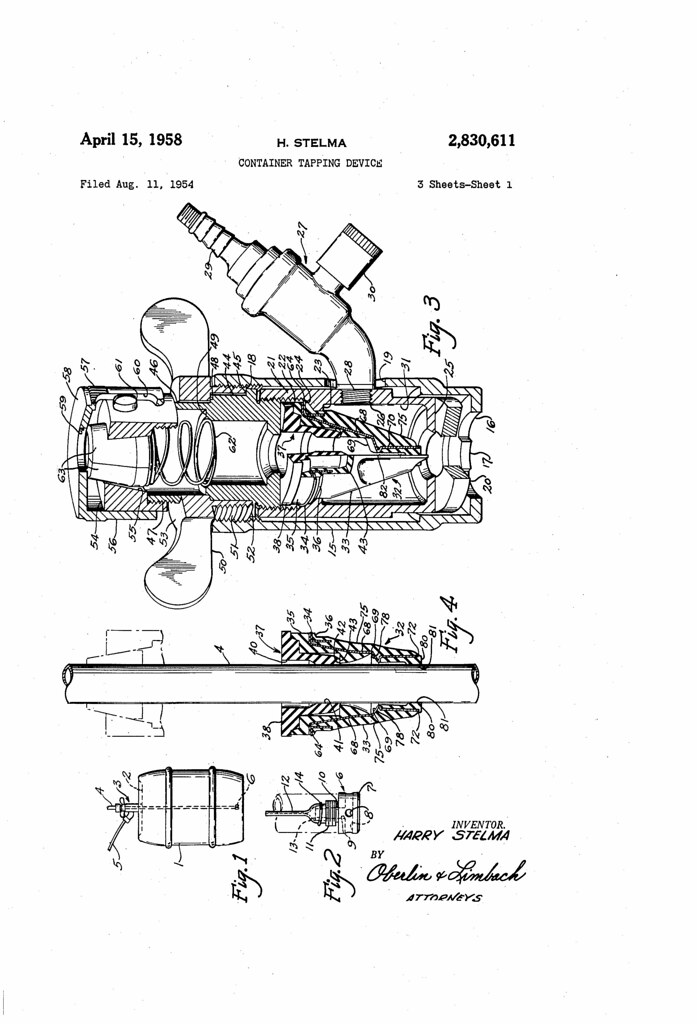

Patent No. 2830611A: Container Tapping Device

Today in 1958, US Patent 2830611 A was issued, an invention of Harry Stelma, assigned to the Champion Safe Tap Co., for his “Container Tapping Device.” There’s no Abstract, but the description states it’s an “invention [that] relates, as indicated, to container tapping devices and, more particularly, to an improved device of this nature adapted to be used safely and efficiently to tap containers in which fluid is maintained under pressure,” which continues in greater detail:

My improved tap is intended principally for use in withdrawing beer from the usual kegs in which the beverage is transported and stored and will, accordingly, be considered and described in detail in connection with such an application thereof. As is well-known, considerable care must be exercised in the common practice of tapping a beer keg by using the draft tube to force the bung into the keg, since the resultant release of pressure may tear the tube from the users hands and cause body injury. The tapping device of my invention includes means preventative of such blowing of the draft tube.

Patent No. 1800632A: Method Of Preparing Hop Extract And Products Containing Hop Extract

Today in 1931, US Patent 1800632 A was issued, an invention of Emil C. Horst, for his “Method Of Preparing Hop Extract And Products Containing Hop Extract.” There’s no Abstract, but the description says simply it’s an “invention [that] relates to a method of preparing hop extract and the product obtained, the object being to obtain a hop extract containing all the desired constituents of hops of value for the manufacture of non-prohibited cereal beverages and other non-prohibited products.” And here’s how he summarizes it:

The method briefly stated consists first in extracting the volatile matter or oil from the fresh or dried hops. Secondly to extract the bitter constituents consisting of soft resins, the tannins, the coloring matter and the foam producing constituents, and third to combine the volatile oil of the hops and the extract to obtain a product containing all the constituents of hops required for the brewing of cereal beverages.

Patent No. 2076893A: Beer Dispenser

Today in 1937, US Patent 2076893 A was issued, an invention of Aron E Johnson, for his “Beer Dispenser.” There’s no Abstract, but the description says simply it’s an “invention relat[ing] to improvements in beer dispensers and aims primarily to provide a beer dispenser especially designed and constructed to avoid the defects previously existent in devices of this type.” Here’s the full story:

The beer dispensers heretofore in use have been defective in that no cushioning means was provided between their outer casings and their fragile beer containers, which in consequence resulted in 1o frequent breakage of the latter. Further, no provision was made heretofore for insulating the covers of such dispensers, hence the contents of the latter became warm and flat in a comparatively short time. Furthermore, no provision was made heretofore for sealing the covers and faucets of these beer dispensers, which fact resulted in the tampering with the contents of the same during the transportation thereof from the producing plants to the consumers.

The present invention, therefore, has for its purpose to obviate the above described defects. This has been primarily attained by providing cushioning means between the lower end of the outer casing and the fragile beer container, thus minimizing breakage of the latter, also by providing the present dispenser with an insulated cover which `protects the beer from becoming warm and at, and also by providing sealing means for the cover and faucet of the instant dispenser which effectively and positively prevents tampering with its contents during transportation, all of which features are to be correlated in the broad aim of enhancing the efficiency of the device for the uses and purposes for which it is primarily designed and intended.

Patent No. 580536A: Process Of And Apparatus For Finishing Beer

Today in 1897, US Patent 580536 A was issued, an invention of Jacob F. Tiieurer and Paul Fischer, assigned to The Pabst Brewing Company, for their “Process of and Apparatus for Finishing Beer.” There’s no Abstract, but the description says simply it’s an “invention which will enable others skilled in the art to which it pertains to make and use the same, reference being had to the accompanying drawing, and to the letters of reference marked thereon, which forms a part of this specification. The main object of our invention is to finish beer and other beverages in such a way as to give them the desired freshness, vivacity, and keeping qualities, and in the attainment of that object to economize space and time and to produce a superior article.”

Patent No. 2466892A: Beer Tap

Today in 1949, US Patent 2466892 A was issued, an invention of Stanley B. Holmes, for his “Beer Tap.” There’s no Abstract, but the description says simply it’s an “invention relat[ing] to beer taps:

First: To provide a beer tap which is adapted to interlock with the conventional latching means provided on beer kegs in a manner to form a sealing connection between the keg and a delivery tube.

Second: To provide a beertap which may be readily and quickly connected or disconnected with a minimum of effort without the aid of tools but which, when connected, cannot read– ily be accidentally loosened.

Third: To provide a beer tap which is particularly simple in its construction and readily cleaned.

Fourth: To provide a beer tap which includes a mounting structure which may be installed or removed without the delivery tube in place, and wherein the delivery tube may be inserted or removed without disturbing the connection between the mounting structure and the beer keg, or, if desired, both may be removed or installed simultaneously, the delivery tube remaining fixed in its position.

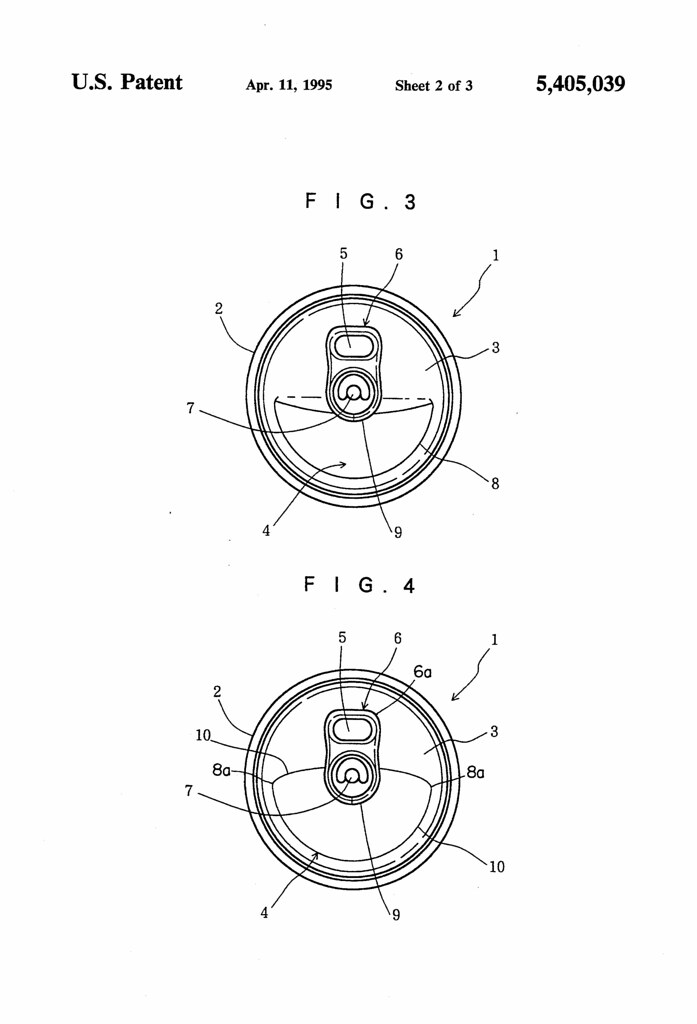

Patent No. 5405039A: Can For Beverage

Today in 1995, US Patent 5405039 A was issued, an invention of Masahiro Komura, for his “Can For Beverage.” Here’s the Abstract:

A can for containing a beverage has a cylindrical body, a top lid for forming an opening through which the beverage can be drunk from the can, a small tab having a finger-receiving hole staked to a central portion of the top lid with a staking member, and a line of weakness defining the opening. This line is in the form of a segment of a circle centered about the staking member. This segment is between an approximately semicircular segment and a 90 degree segment.

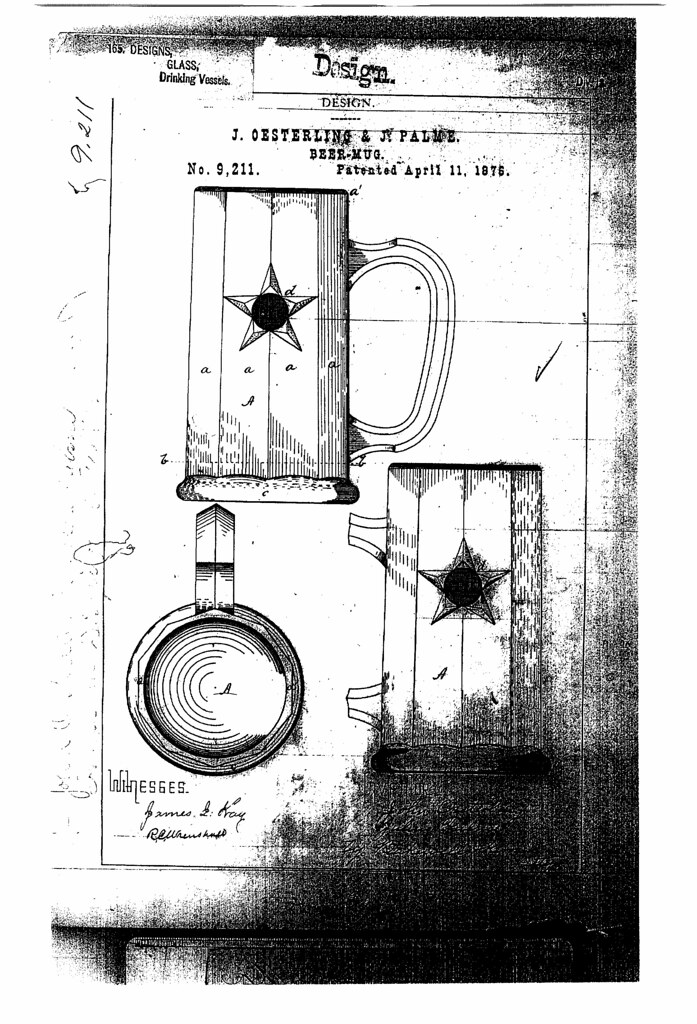

Patent No. D9211S: Design For Beer-Mug

Today in 1876, US Patent D9211 S was issued, an invention of John Oesterling and Julius Palme, for their “Design for Beer-Mug.” There’s no Abstract, but it’s claimed that they have “invented a new and useful Improvement in Design for Beer-Mugs or Ale-Glasses, with or without foot or stein; and we do hereby declare the following to be a full, clear, and exact description thereof, reference being made to the accompanying drawing forming part of this specification, and illustrating our design as applied to a beer-mug. Our design is intended for beer-mugs or ale glasses, with or without foot or stems, and consists in forming the exterior of an ale or beerglass of a series of planes upon one or more of which star-shaped figures are formed.”

Patent No. 989546A: Bottle-Filling Machine

Today in 1911, US Patent 989546 A was issued, an invention of Mathias Jensen, for his “Bottle-Filling Machine.” There’s no Abstract, but there’s this description. “invented a new and Improved Bottle-Filling Machine, of which the following is a full, clear, and exact description.”

This invention relates to certain improvements in machines for filling bottles, cans, or other containers with liquid or semi-liquid` substances, and more particularly to that type of machine in which a series of empty containers are continuously delivered to the machine, automatically filled in succession, and continuously delivered thereof. In a filling machine embodying all of the various features of my invention, the containers are conveyed along an endless belt to the machine and the latter operates to remove them from the belt, fill them in succession, and return them to the belt. The machine is so constructed that after filling each bottle, the liquid is removed from the bottle to a predetermined level below the mouth thereof, irrespective of slight variations in the height of successive bottles.

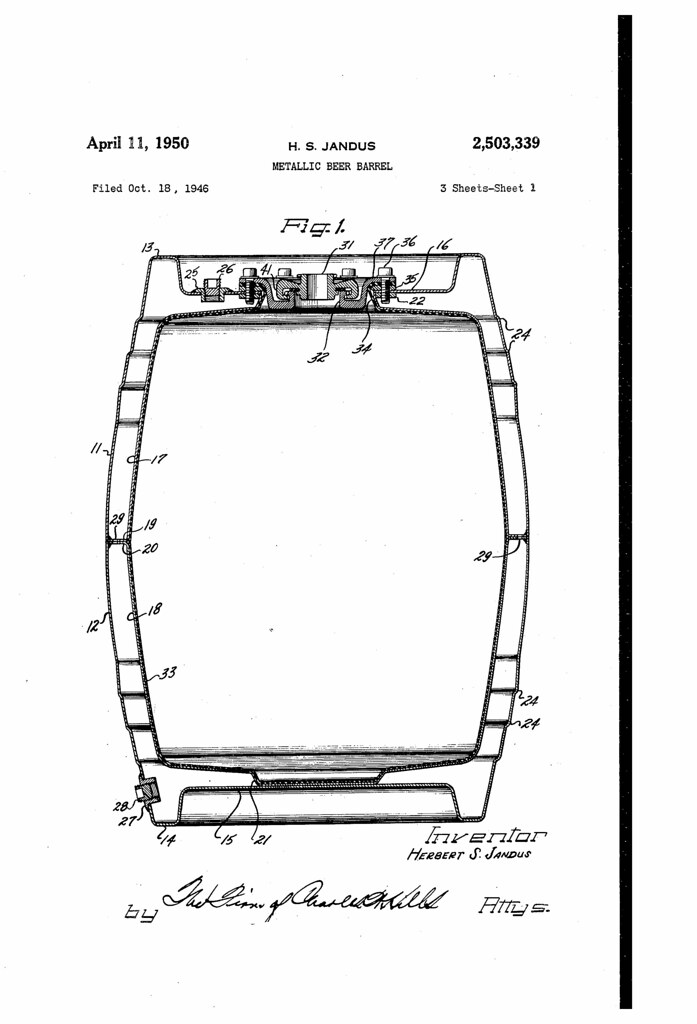

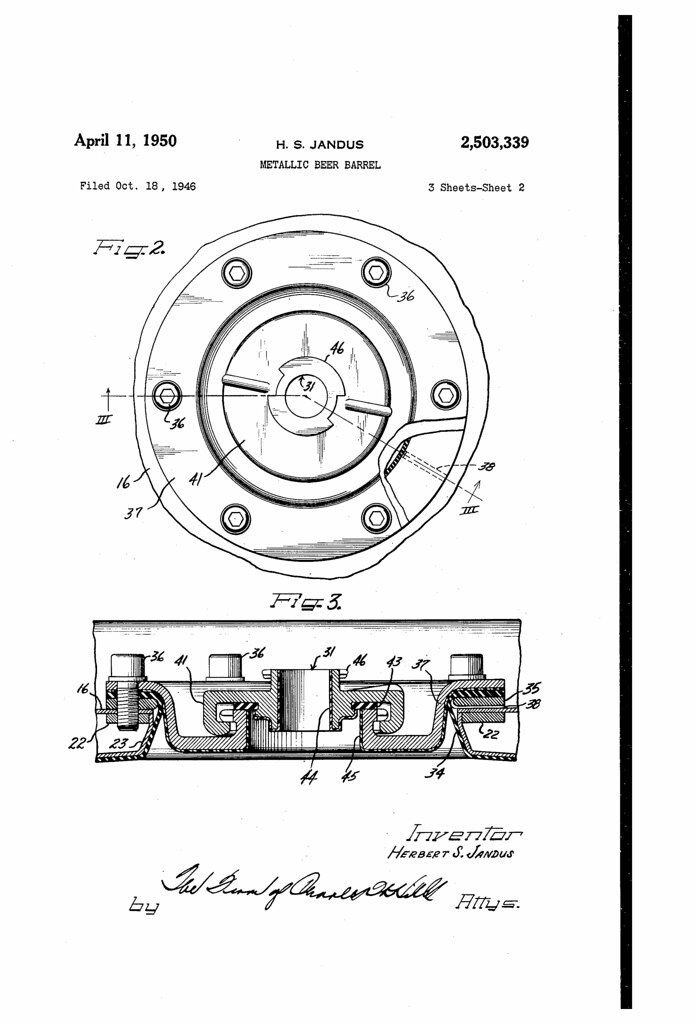

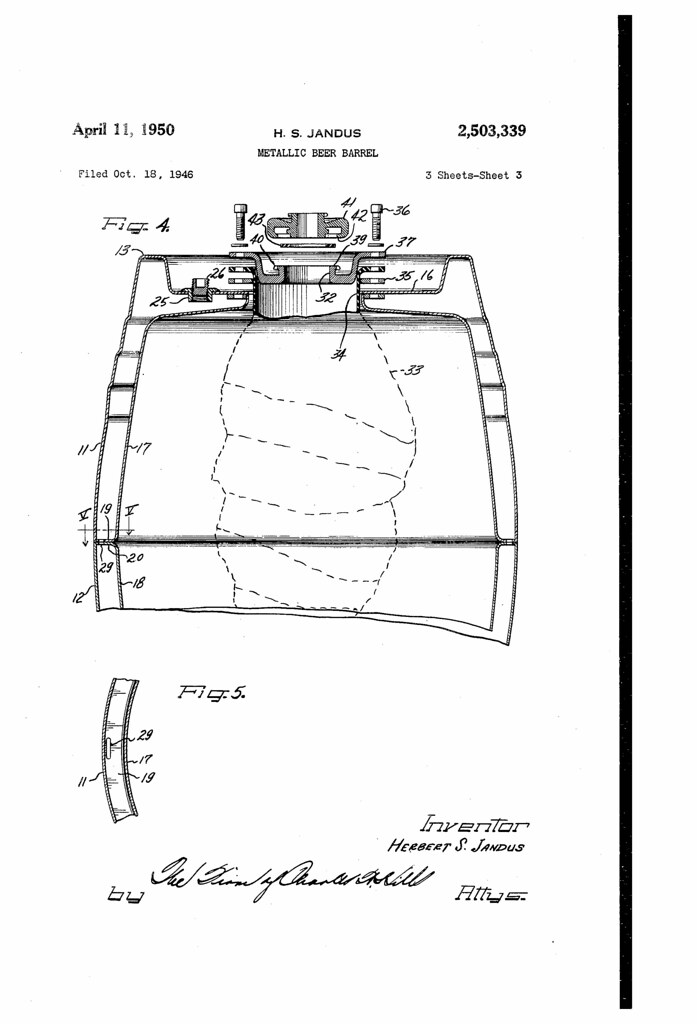

Patent No. 2503339A: Metallic Beer Barrel

Today in 1950, US Patent 2503339 A was issued, an invention of Herbert S. Jandus, for his “Metallic Beer Barrel.” There’s no Abstract, but there’s this description. “This invention relates to double walled containers and more particularly to double walled beer barrels made from sheet metal stampings and provided with a removable or permanent liner made of a material suitable as a container for beer,” and then a few more specific reasons for the metal keg design.

By constructing such a barrel with double walls, a number of advantages are gained thereby. A sturdy construction of sufficient rigidity to withstand the hard usage to which these barrels are ordinarily subjected can be formed of relatively thin sheet material by’ stamping methods, portions of the total structure being made in sections which are subsequently secured together, and yet the total weight can be kept within satisfactory limits. To accompany the advantage of using sheet metal suitable for stamping, provision is made for the lining of the inner shell so that the metal itself need not be one that is especially adapted because of its inertness for the reception of beer or other edible Products.

A double walled construction is readily adapted for the provisions of an opening into the interior shell, larger than the usual filling opening or tap rod opening such as are usually provided in wooden barrels, for example. Such an enlarged opening can be used to facilitate the cleaning and the inspection of the barrel, and may also be used for the insertion and removal of a separate removable liner.