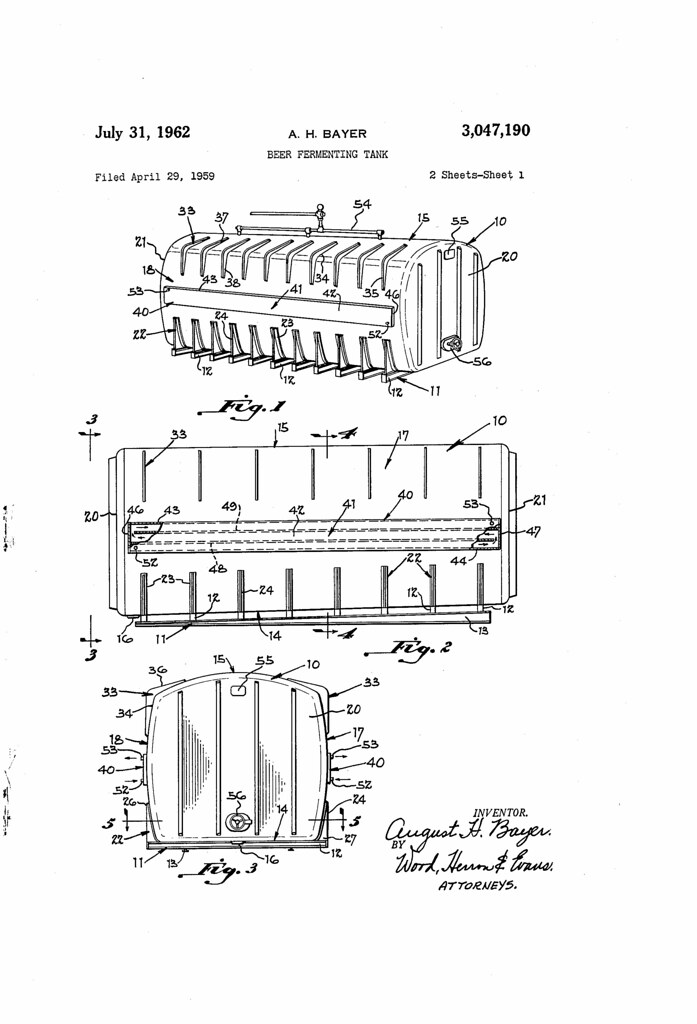

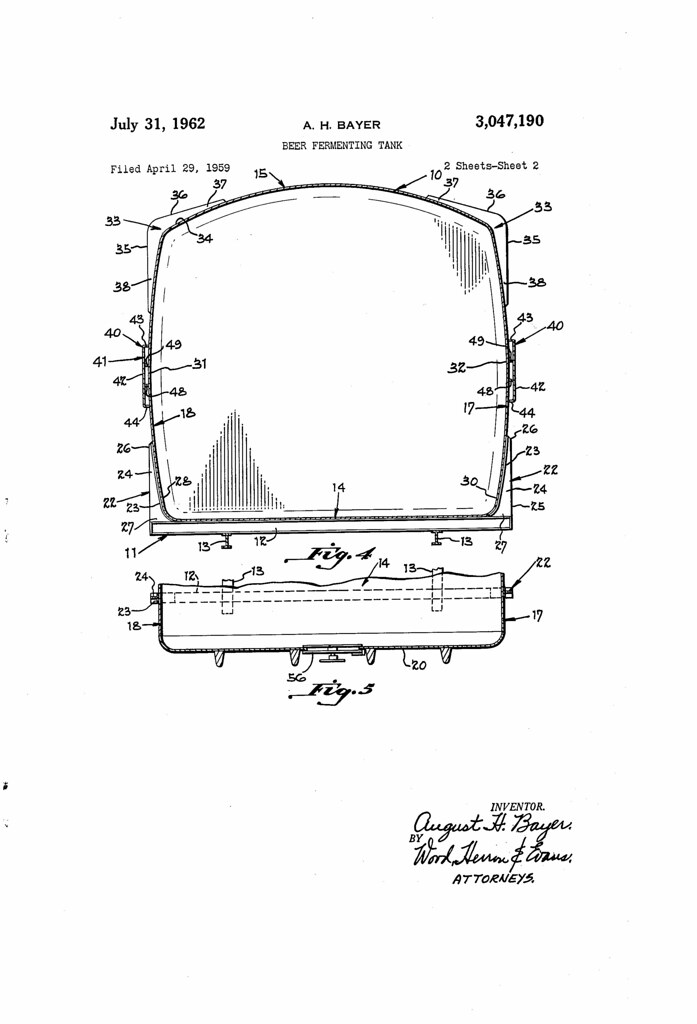

Today in 1962, US Patent 3047190 A was issued, an invention of August H. Bayer, for his “Beer Fermenting Tank.” There’s no Abstract, although in the description it includes these claims:

This invention relates to storage tanks and is particularly directed to a novel closed fermenting tank for use in the brewing industry.

It is common practice in breweries to use fermenting tanks in which beer is fermented for an appreciable length of time under controlled pressure and temperature conditions. While the size of these tanks varies, a typical fermenting tank is adapted to contain 1300 barrels of beer. The tank is substantially filled with beer except for an air space at the top of the tank to permit collection of gases produced during the fermentation process. It will readily be appreciated that the walls of the fermentation tank are thus subjected not only to the hydrostatic loads caused by the contained liquid, but in addition are subjected to stresses induced by the resultant gas pressure.

In the past, it has been conventional in breweries to construct fermentation tanks of rectangular cross-section and to provide a plurality of spaced reinforcing ribs which extend completely around the tank; i.e., across the top and bottom Walls and upwardly along the side walls of the tank. While tanks of this type have proved to be satisfactory from a strength standpoint, they utilize an excessive amount of floor space for a given capacity because of the reinforcing members on the sides of the tank.

It is an important object of the present invention to provide a fermenting tank in which a maximum usable capacity is obtained for the door space occupied by the tank. Thus, a tank constructed in accordance with the principles of the present invention provides approximately eight percent more capacity than a tank having the same overall dimensions of the conventional type referred to above.

The present invention is predicated in part upon the concept of providing a tank structure in which only the upper and lower portions of the side walls are reinforced to resist stresses as a beam, while the center portions of the side walls are intentionally left unreinforced, are slightly curved, and are made of a relatively thin material so that these walls undergo large deflections and thus function as membranes.

More particularly, one preferred form of tank constructed in accordance with the principles of the present invention comprises a bottom member which is supported on a plurality of spaced transverse beams, or box type sections. Two arcuate side walls are welded to the bottom, and to a top, and end members to form a closed tank. The side walls are reinforced by a plurality of spaced upper and lower stiffener members which extend upwardly approximately of the height of the tank from the bottom of the tank and downwardly approximately of the height of the tank from the top. Thus, the upper and lower portions of the side walls of the tank adjacent to these stiffeners function as a beam; i.e., members adapted to resist sizable bending stresses. The center portions of the tank side walls, however, are completely unreinforced and these portions of the side walls, which are curved outwardly and are thinner than the side walls of conventional tanks, are adapted to deflect outwardly an appreciable amount; for example, more than one inch for a of an inch side wall. This portion of each side wall thus functions mechanically as a membrane; that is, a member which may be subjected to ant liquid is circulated to remove excess heat and main large tensile stresses (which the side walls can readily resist without yield), but is not subjected to sizable bending stresses (which the side walls could not resist without yield).

Additionally, in accordance with the present invention, the lower stiffener members are of tapered configuration having a wide base adjacent to the bottom portion of the tank and a narrow upper end. Thus, these reinforcing members function as cantilever beams having a greater outward deflection adjacent at their upper ends than at their lower ends so that the reinforcing members help to provide a smooth transition in the side walls between the areas of the side walls which function as a beam and those areas of the side wall which function as a membrane. 7

in further accord with this invention, each of the upper stiffener members is of double tapered configuration including one arm extending downwardly along the upper portion of the side walls, and a second arm extending particularly, it is well known that during the fermenting process a certain amount of heat is developed which tends to raise the temperature of the beer above the optimum temperature for fermentation. Accordingly, it is conventional to provide on the interior of a fermentation tank an elongated at temperator coil through which a cool train the beer at a predetermined temperature. One of the obvious difficulties with interior coils of this type is that of cleaning the surface of the coil to keep it in a sanitary condition.