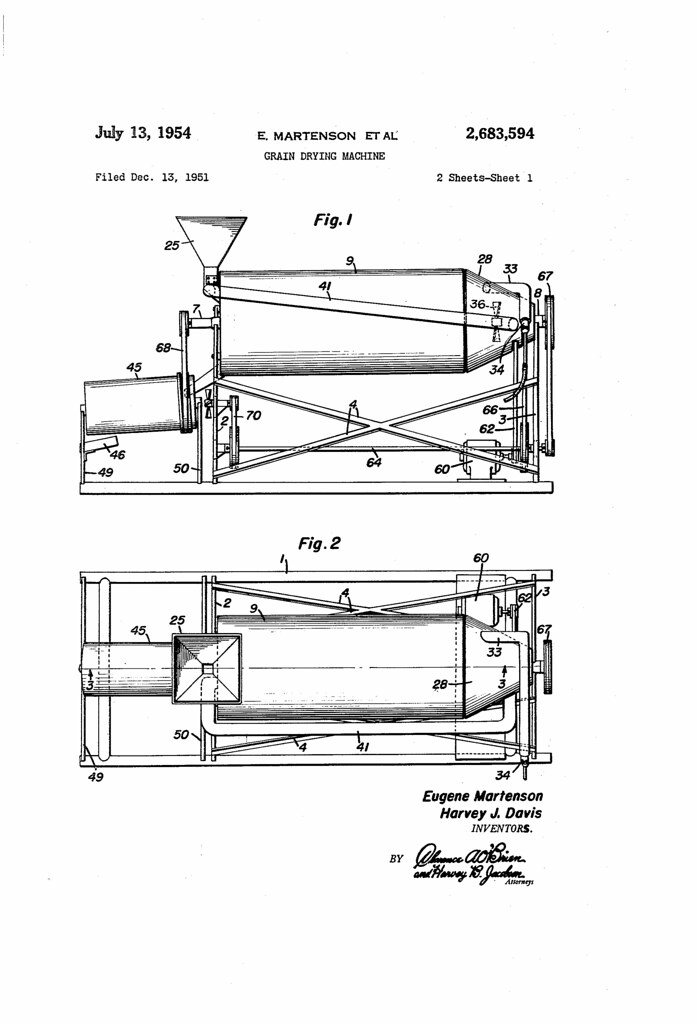

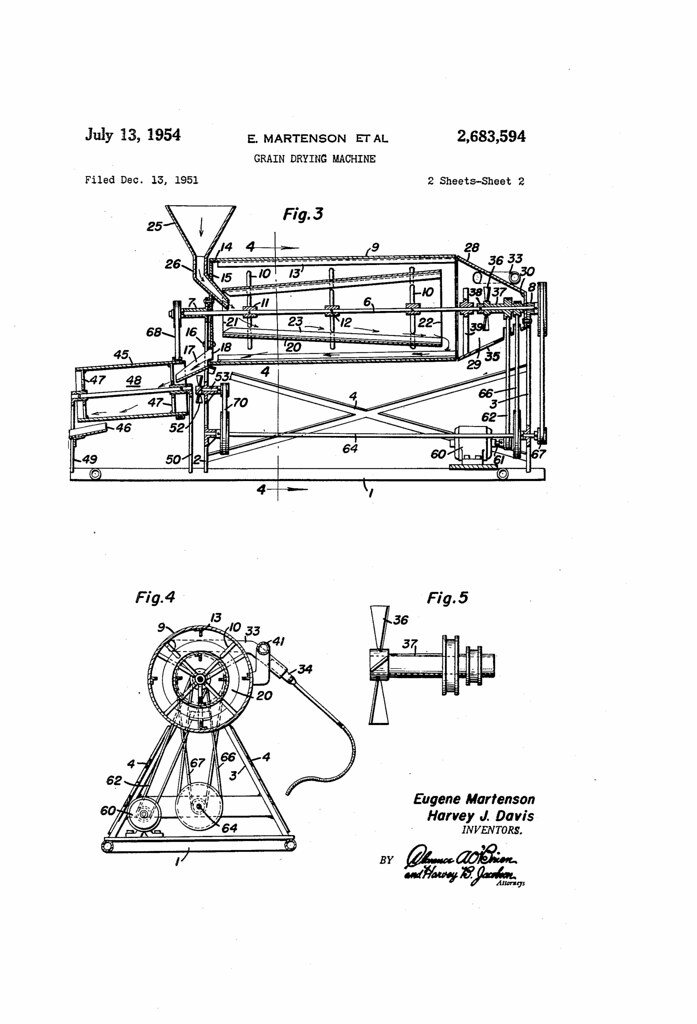

Today in 1954, US Patent 2683594 A was issued, an invention of Harvey J. Davis and Eugene Martenson, for their “Grain Drying Machine.” There’s no Abstract, although in the description it includes these claims:

Our invention relates to improvements in grain drying machines for small grain, especially oats, wheat, rye, barley and corn.

The primary object of our invention is to provide an efficient portable machine for removing, under the action of heat a sufficient amount of moisture from such grain to prevent molding, but, without damaging the grain as regards germination, color, odor, or taste.

Another object is to accomplish the above while agitating the grain so that it will be uniformly but slowly dried under the action of heat at a low temperature.

Still another object is to provide a machine for the above purposes which is economical to manufacture, use and service, and easily cleaned.