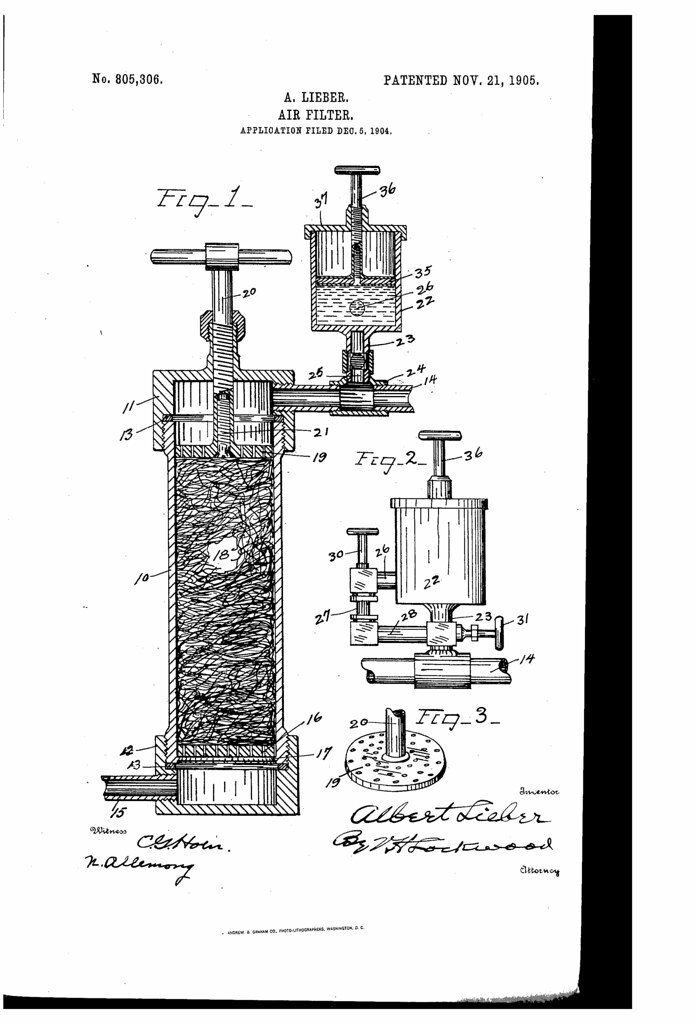

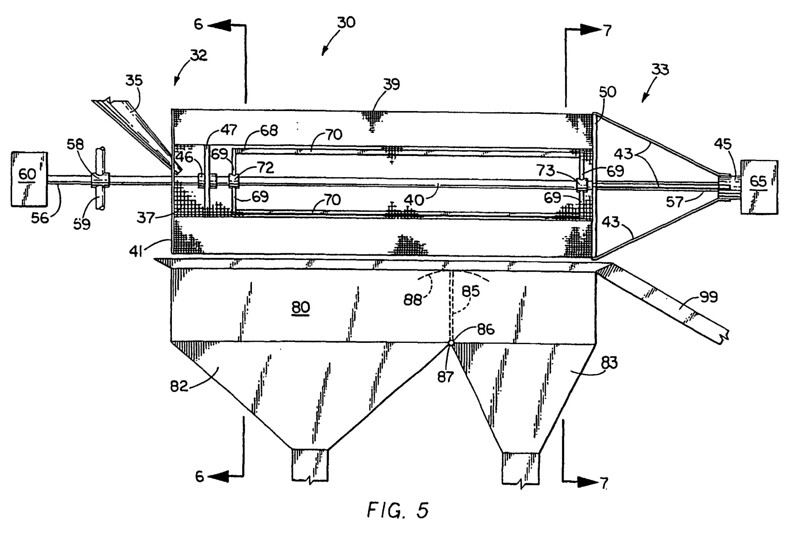

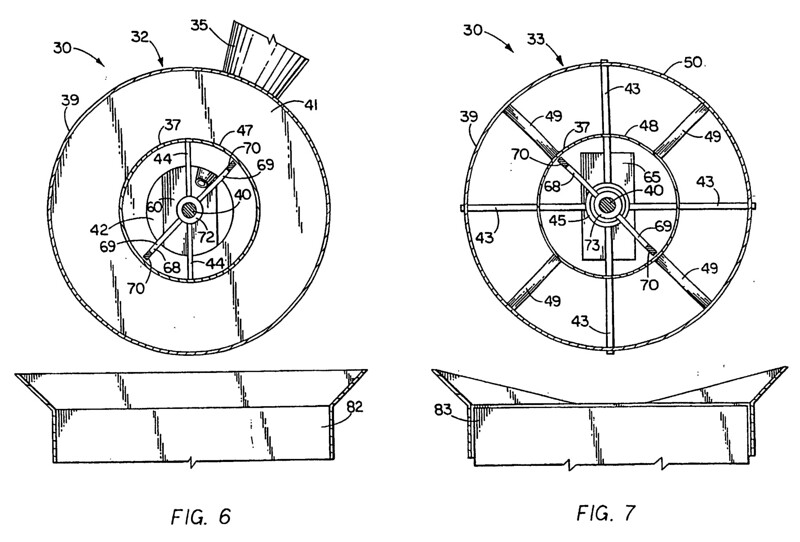

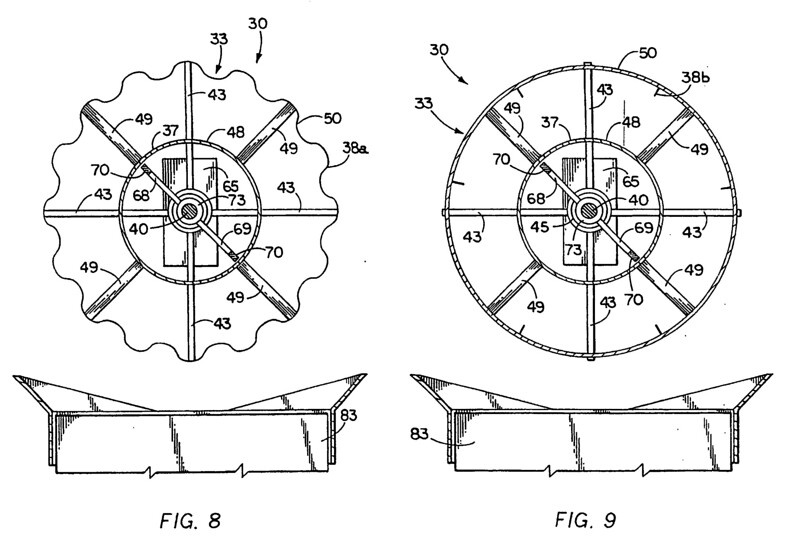

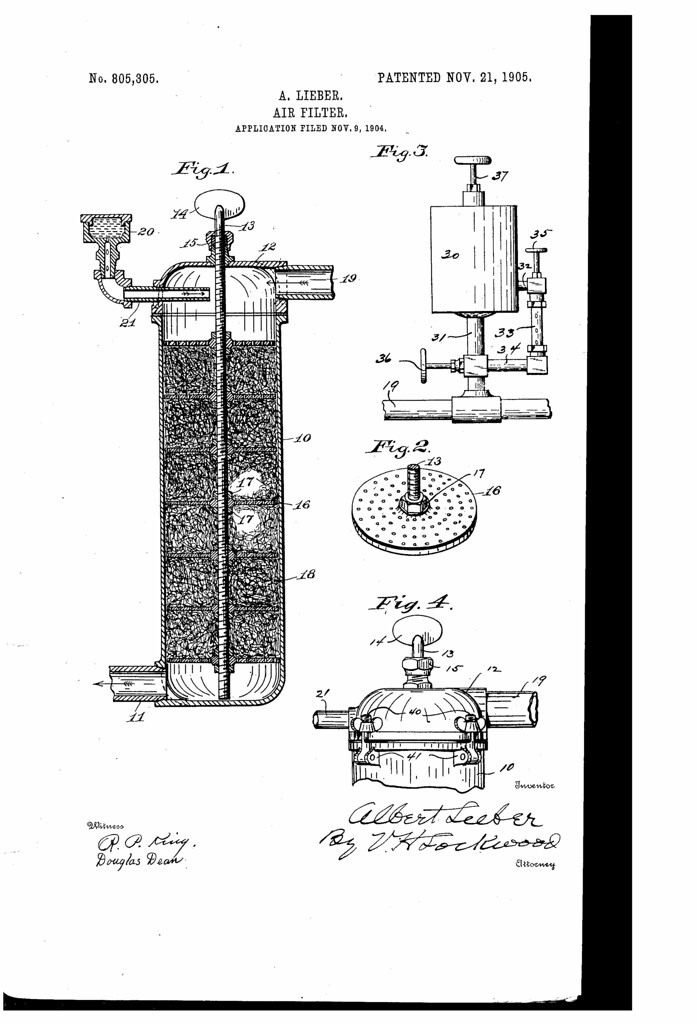

Today in 1905, both US Patent 805305 A and US Patent 805306 A were issued, and both are related inventions of Albert Lieber, under the same name: “Air Filter.” There’s no Abstract, although in the description it includes these claims for the first one:

The object of this invention is to provide an improved construction of air-filter for filtering compressed air and removing from it impurities as well as chemically treating it during its passage through the filter.

The use to which I. have put this filter is for pitching the interior of beer-kegs and the like for blowing and spreading the warm pitch upon the internal surface of a keg by compressed air passing through this filter. In such case the bacteria and germs in the air will be embedded in the pitch and thus affect the beer, impairing its preserving qualities as well as its taste. It is therefore found very important by me that the compressed air used for the purpose mentioned be rendered chemically pure by passing the air through medicated cotton, thus arresting the particles of dust, microbes, germs, and the like. Beer-kegs treated in this way can be used immediately after being pitched and after prior use without the necessity of treating the kegs as heretofore.

And here’s a description of the claims for the second patent:

The chief feature of this invention consists of means for compressing the cotton or filtering material to the degree best suited for the chemical through which the air passed through the device is being treated.

The purpose of the invention, therefore, is to more thoroughly arrest the bacteria and germs of the air in the filter before the same passes through the filter. I have used it for pitching the interior of beer-kegs, the air being passed through the filter and compressed for blowing and spreading warm pitch upon the internal surface of the keg. This device prevents the bacteria and germs from the air entering the pitch.