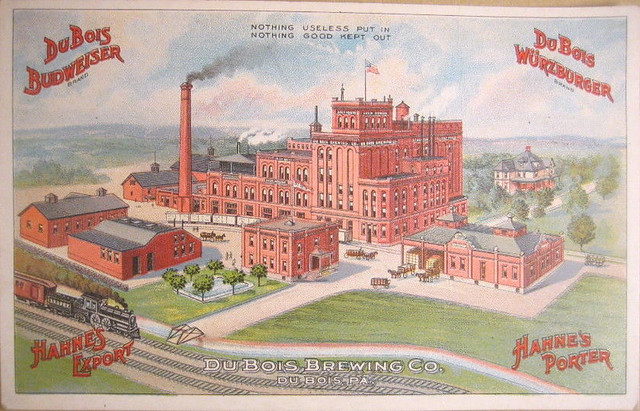

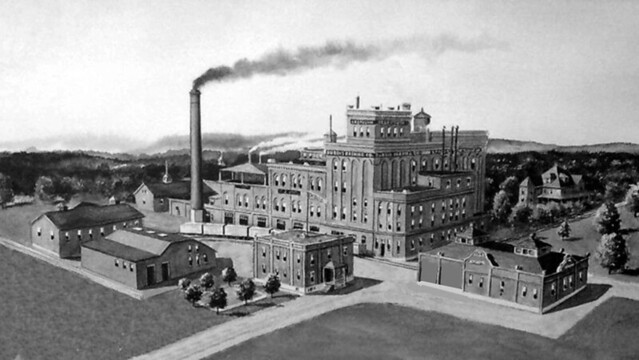

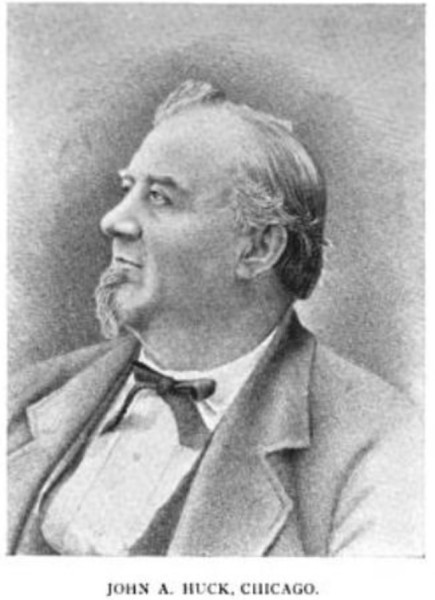

Today is the birthday of John A. Huck (May 15, 1818-January 26, 1878). He was born in Baden-Württemberg, Germany, and in 1847 he came to the U.S. and settled in the Chicago, Illinois area. In 1847, long with a partner, John Schneider, he founded the John Huck & John Schneider Brewery, but for five years beginning in 1855 it was known as the Eagle Brewery, but apparently he bought out Schneider in 1860, when its name was changed again, this time to Huck’s Chicago Brewing Co. and then 1869 became the John A. Huck Brewing Co. But in 1871, the brewery was destroyed by the Great Fire and never reopened after that. A few years before, his son, Louis C. Huck, opened his own malting business, the L.C. Huck Malting Co., so maybe he went to work with him or simply retired.

Here’s account of Huck by Gregg Smith from RealBeer.com:

The story begins in 1847, shortly after lagers arrived in America, when John Huck entered a partnership with John Schneider to construct a brewery. Located just two blocks east of Chicago’s first ale brewery (Lill’s Cream Ale) it had an interesting connection to that facility. Chicago’s first mayor, William Ogden, who had a financial interest in Lill’s, owned the land at Chicago Avenue and Division Street which Huck and Schneider purchased for their facility.

This location provided another innovation in Chicago beer drinking. The property included a tree filled square, and in the center Huck put his house. This he surrounded with a beer garden, another first in the city. More than just a retail outlet for their product, brewers in Europe had long built beer gardens for a more practical reason. An essential part of lager brewing is cool temperatures. These are needed for lager yeast to work its magic. For this reason brewers aged the beer in subterranean “lagering cellars”. The trees of the beer garden, usually elm, provided a shady canopy on the ground above and helped ensure cellars would remain lager friendly cool.

Huck’s beer was a success and rather than sacrifice his home and beer garden to expansion he moved brewing operations in 1855 to a new facility on Wolcott (now N.State Street) near Division. With the move came a new name – Eagle Brewing. The new brewery was, in its day, one of the city’s largest. It boasted both brew and malt houses along with more than 2 miles of underground vaults. The name changed again in 1860, to Huck’s Chicago Brewing Co. and from 1869 to 1871 was known as John A. Huck Brewing Company.

This is from a blog post about The Huck Tunnels:

In the 1840s, Huck opened the first lager brewery in Chicago at Chicago and Rush, back when the area was still practically the wilderness. In the 1850s he moved to a new location at Banks and Astor, just south of the Catholic portion of City Cemetery (now Lincoln Park), which started at Schiller. The area seems to have been bounded by State and Astor at the West and East, and from Banks to Goethe from the North to South – a full square block, across the corner from the future Playboy mansion, though one source says that it went clear north to Schiller. In what was then quite an innovation, the brewery featured a whole network of subterranean tunnels and vaults for brewing the beer at low temperatures year round, and apparently there were two full miles of them in total. The brewery was destroyed in the Great Chicago Fire in 1871, but the tunnels remained.

And this is from One Hundred Years of Brewing:

The first lager beer brewery in Chicago and one of the first to manufacture any kind of malt liquor was that founded on the corner of Chicago avenue and Rush street, by the late John A. Huck, in 1847. Two blocks cast was Lill’s cream ale brewery, which had been in successful operation for about eight years. It is worthy of note that Wm. B. Ogden, the first mayor of Chicago, and in many respects its foremost citizen, was identified with ] both of these pioneer breweries; for, as has been stated, he was at first the financial support of the Lill brewery, and it was upon the Ogden block that the Huck lager beer plant was installed—upon the square bounded by Chicago avenue and Superior, Rush and Cass streets. In the center of the square, which was well covered by trees, was Mr. Huck’s residence, which, in turn, was the center of a beer garden—the first in Chicago.

In 1855 Mr. Huck removed his plant to the corner of Banks and North State street, where the residence of Franklin Head now stands, and by the time of the Great Fire it had expanded into one of the most extensive establishments of the kind in the country. With two miles of subterranean vaults and brew and malt houses, in proportion, it was one of the marked sights of the city. In 1871, however, all was swept away and the labors of many years lay in ruins. The property remained idle for several years, but in the latter portion of 1877, Mr. Huck began to lay his plans for a rebuilding of the brewery on the old site. While in the midst of these preparations, however, in January, 1878, he was taken away, leaving, among other children, the Louis C. Huck, who first associated himself with his father in 1861, established an independent malting business in 1869 and is now a well-known capitalist of Chicago.

Two Dans: Daniel Bradford and Dan Carey at the Rare Beer Tasting 2009 at Wynkoop.

Two Dans: Daniel Bradford and Dan Carey at the Rare Beer Tasting 2009 at Wynkoop.