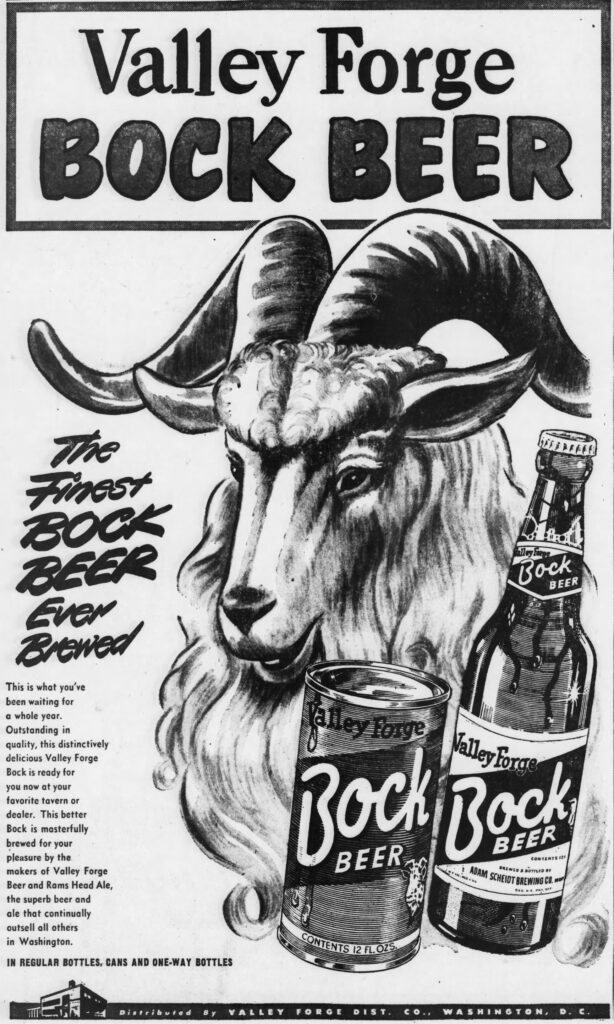

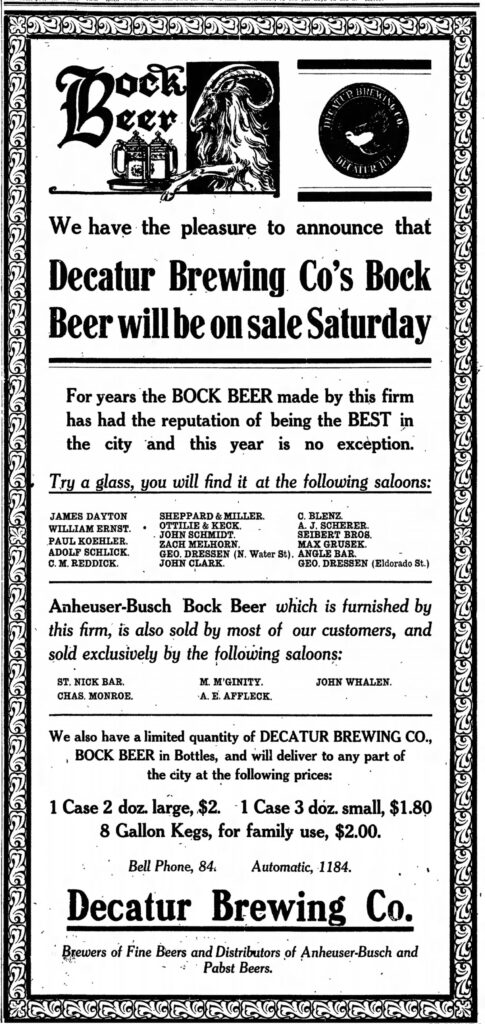

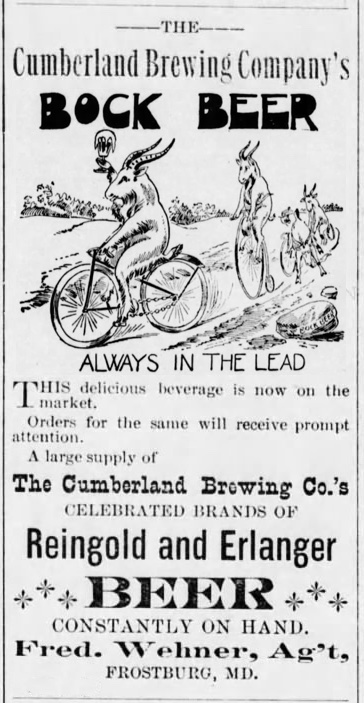

Last year I decided to concentrate on Bock ads. Bock, of course, may have originated in Germany, in the town of Einbeck. Because many 19th century American breweries were founded by German immigrants, they offered a bock at certain times of the year, be it Spring, Easter, Lent, Christmas, or what have you. In a sense they were some of the first seasonal beers. “The style was later adopted in Bavaria by Munich brewers in the 17th century. Due to their Bavarian accent, citizens of Munich pronounced ‘Einbeck’ as ‘ein Bock’ (a billy goat), and thus the beer became known as ‘Bock.’ A goat often appears on bottle labels.” And presumably because they were special releases, many breweries went all out promoting them with beautiful artwork on posters and other advertising.

Wedneday’s ad is for Valley Forge Bock Beer, sort of. I guess it was at the end of Bock season so they used the success of their bock beer to suggest switching to Valley Ford Light Beer for the summer. The ad was published on June 25, 1954. This one was for the Adam Scheidt Brewing Co., which was located in Norristown, Pennsylvania and was originally founded in 1866. This ad ran in The Jersey Journal, of Hudson County, New Jersey.