![]()

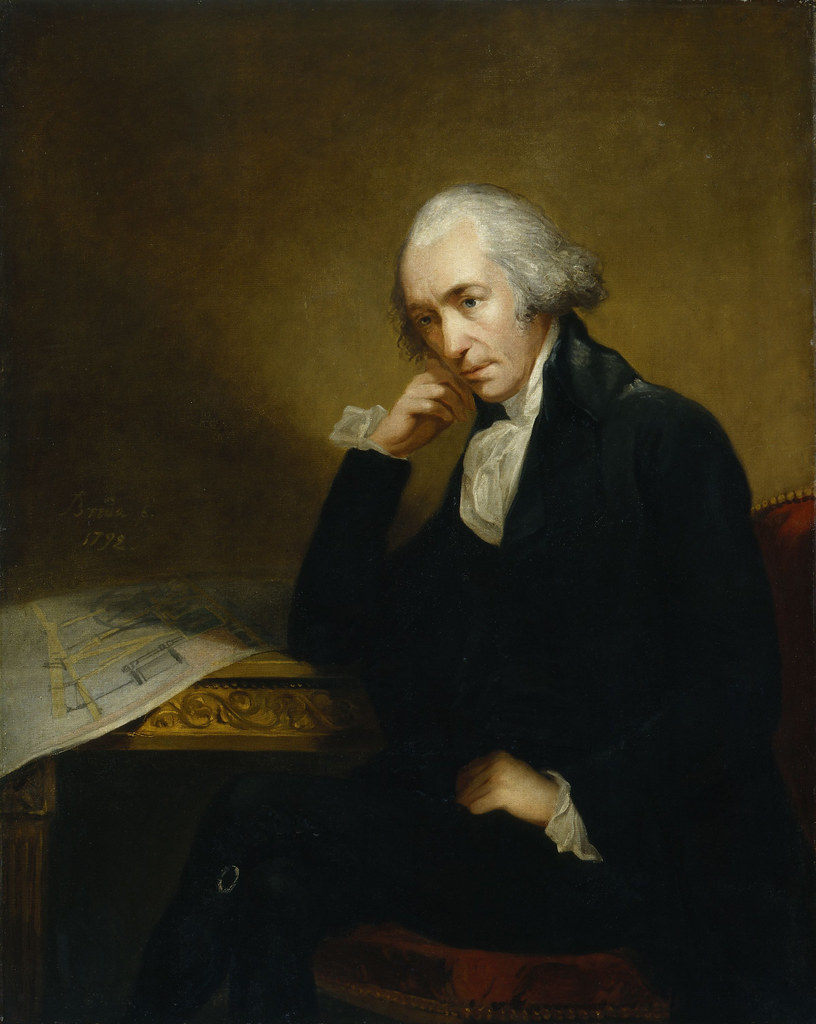

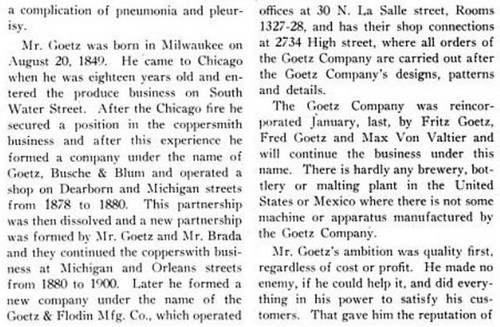

Today is as good a day as any to celebrate the birthday of John Lofting (1659–June 15, 1742). Like many people born centuries ago who weren’t royal or otherwise well-born, we don’t know the exact day he was born, but we do know that he died today. Lofting was a Dutchman who lived in London as an adult, and patented several devices, the most famous of which was the fire engine, but he may also have been responsible for the beer engine.

Here’s his Wikipedia entry:

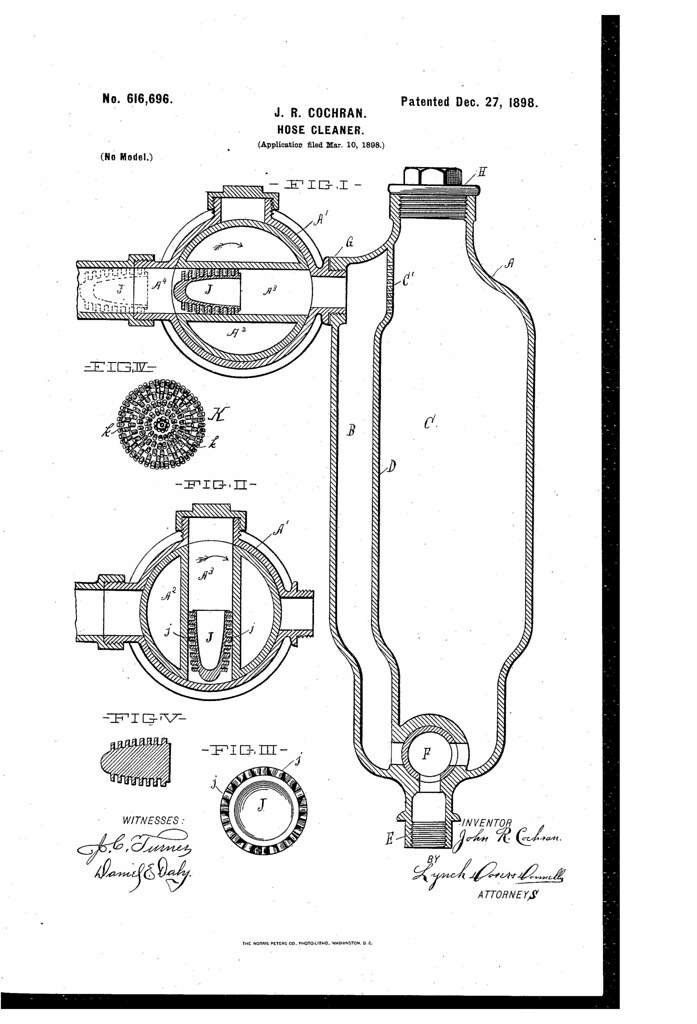

Originally Jan Loftingh, John Lofting was an engineer and entrepreneur from the Netherlands. His parents were Herman and Johanna. He moved to London, England, before 1686. He patented two inventions being the “sucking worm engine” (a fire engine) and a horse-powered thimble knurling machine. His mill was set up in Islington, where Lofting Road is named after him. However, in or about 1700, he moved his main operation to Great Marlow in Buckinghamshire to take advantage of the River Thames’ ability to turn a water wheel which improved productivity, enabling the production of over 2 million thimbles per year.

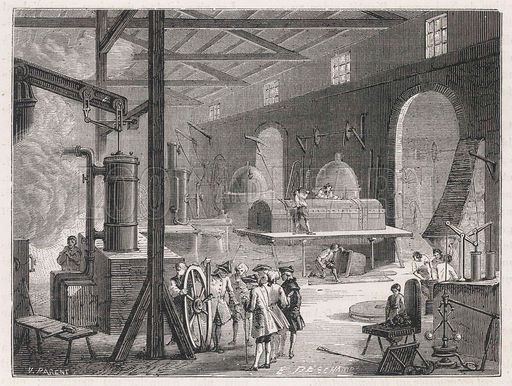

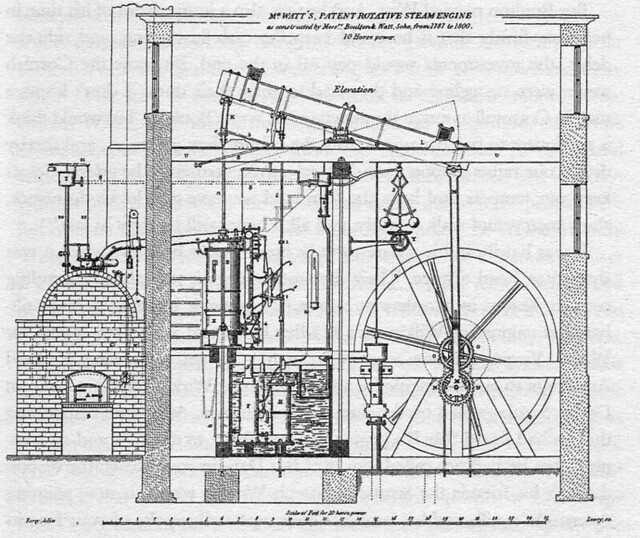

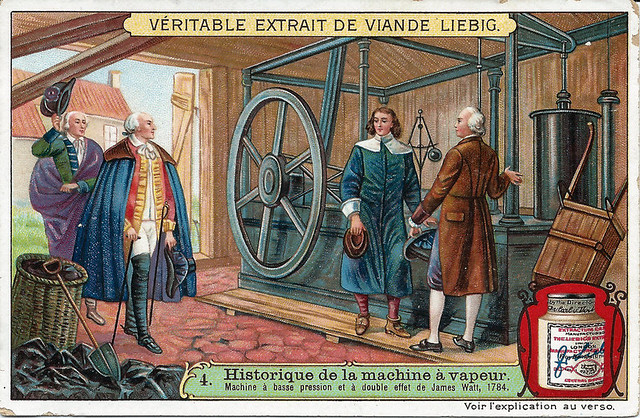

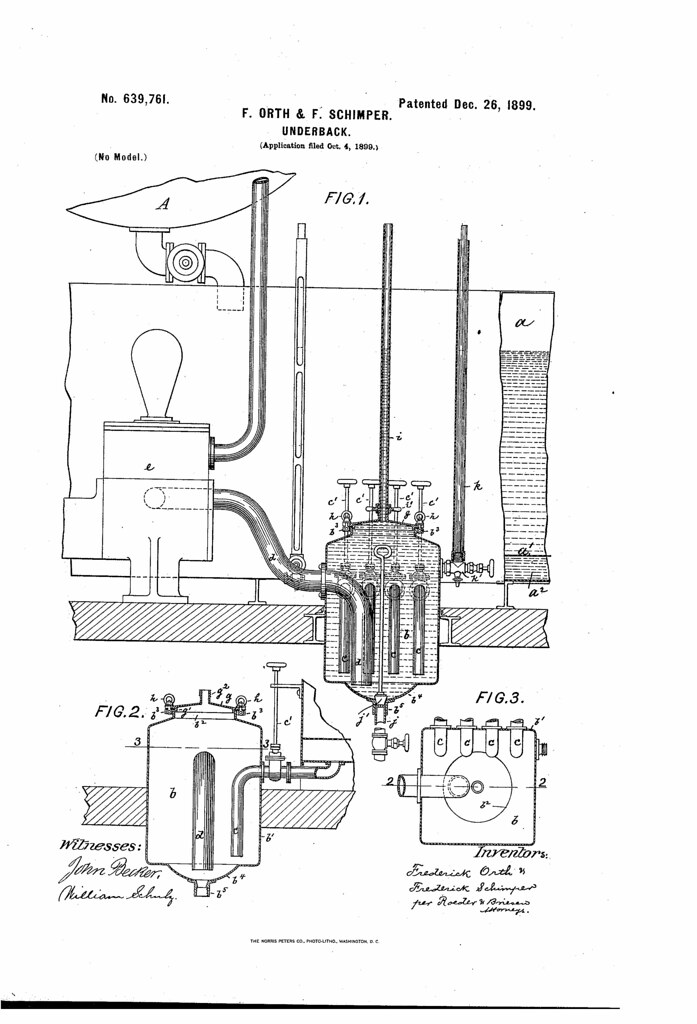

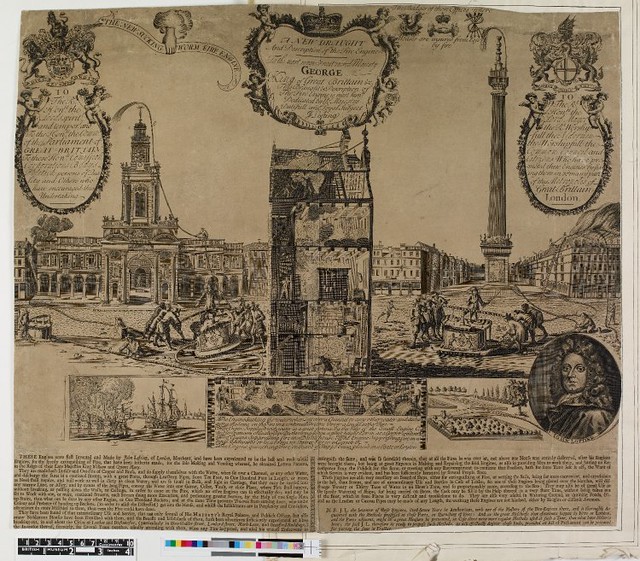

The Sucking Worm Engine, from the British Museum.

And while Joseph Bramah patented the first practical beer engine, Lofting’s design made it possible for Bramah to build on and create his. Although there’s little I could find specific about Lofting’s invention, it is mentioned in the Wikipedia entry for the beer engine:

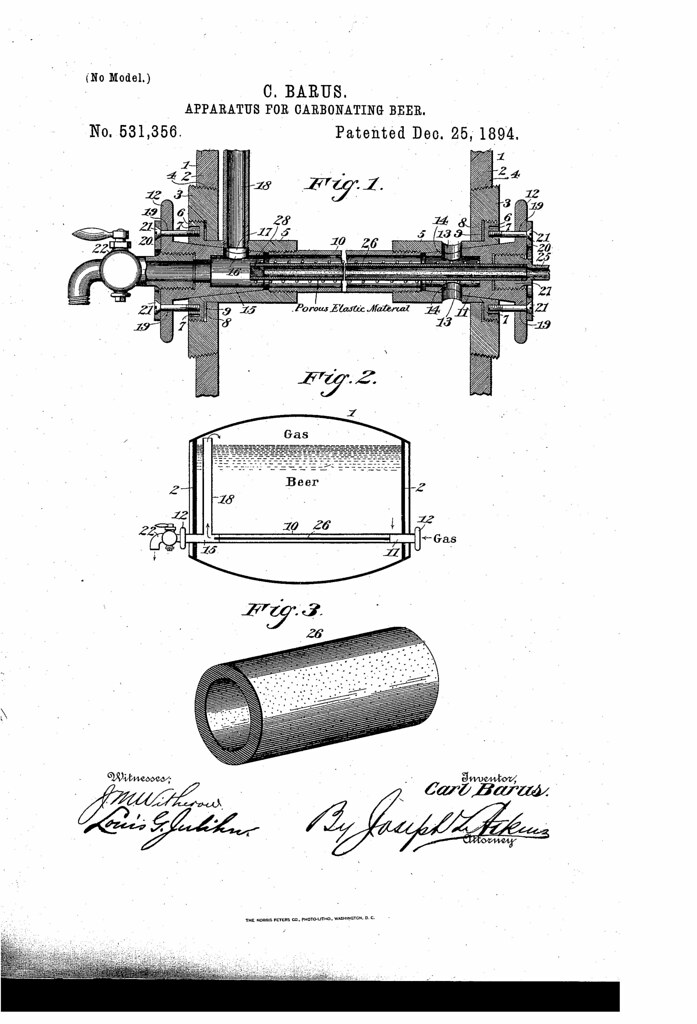

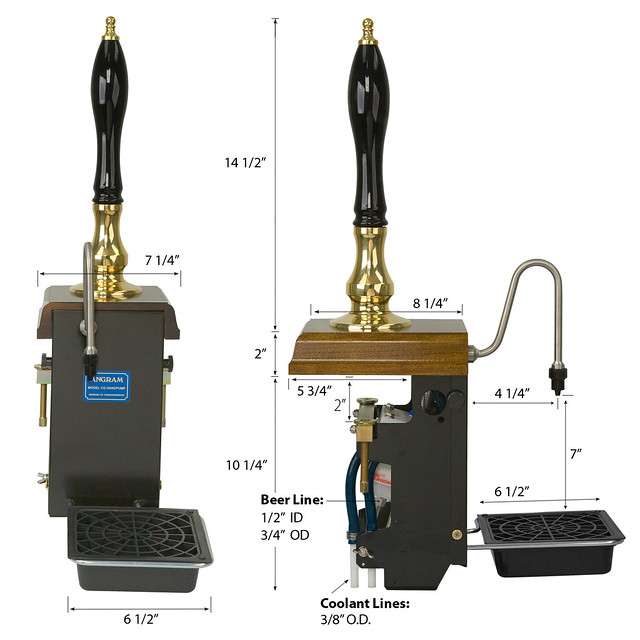

A beer engine is a device for pumping beer from a cask in a pub’s cellar.

The beer engine was invented by John Lofting, a Dutch inventor, merchant and manufacturer who moved from Amsterdam to London in about 1688 and patented a number of inventions including a fire hose and engine for extinguishing fires and a thimble knurling machine as well as a device for pumping beer. The London Gazette of 17 March 1691 stated “the patentee hath also projected a very useful engine for starting of beers and other liquors which will deliver from 20 to 30 barrels an hour which are completely fixed with brass joints and screws at reasonable rates.”

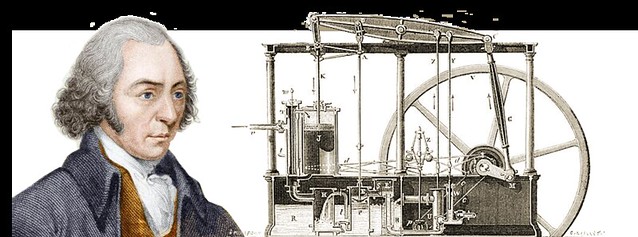

The locksmith and hydraulic engineer Joseph Bramah developed beer pumping further in 1797.

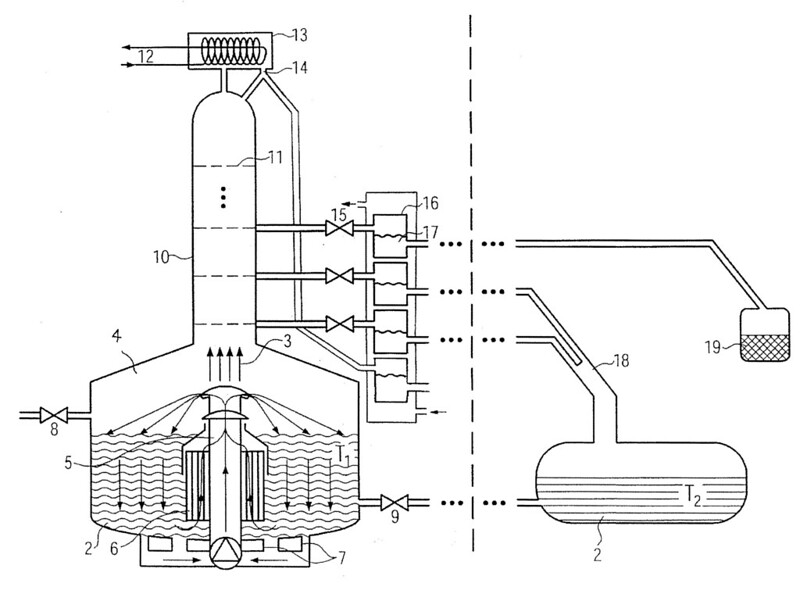

The beer engine is normally manually operated, although electrically powered and gas powered pumps are occasionally used; when manually powered, the term handpump is often used to refer to both the pump and the associated handle.

The beer engine is normally located below the bar with the visible handle being used to draw the beer through a flexible tube to the spout, below which the glass is placed. Modern hand pumps may clamp onto the edge of the bar or be mounted on the top of the bar.

A pump clip is usually attached to the handle by a spring clip giving the name and sometimes the brewery, beer type and alcoholic strength of the beer being served through that handpump.

The handle of a handpump is often used as a symbol of cask ale. Keg beer dispensers usually feature illuminated countertop fittings behind which a handle opens a valve that allows the gas pressure in the keg to force beer to the attached spout.

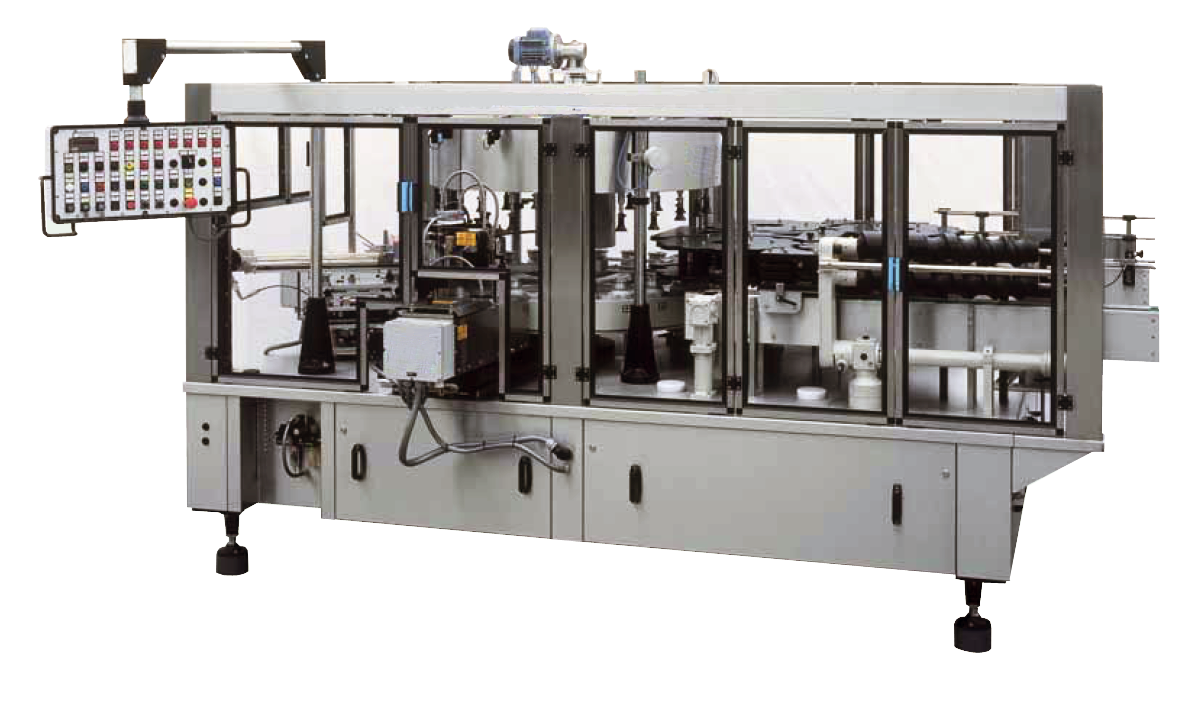

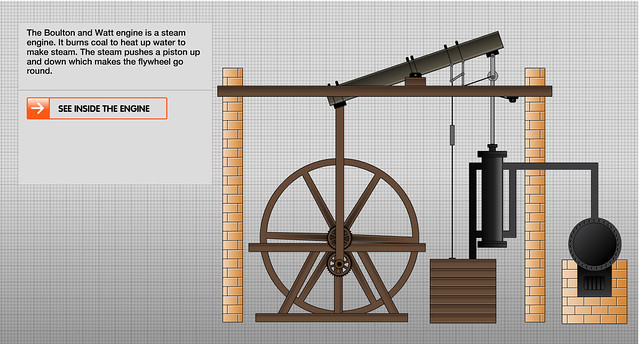

A modern beer engine.