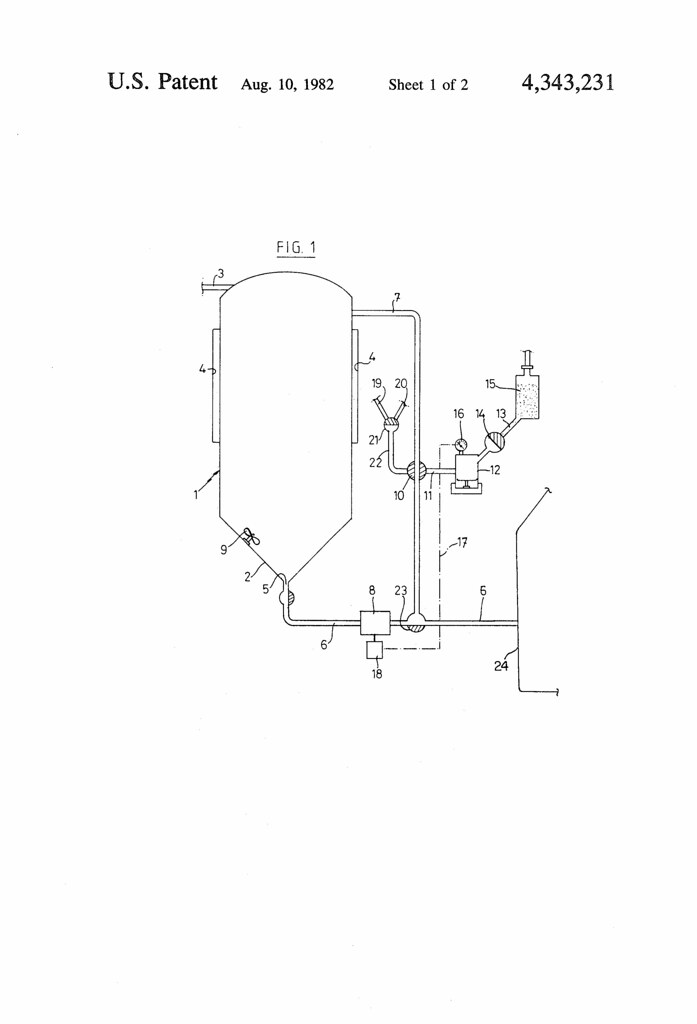

Today in 1982, US Patent 4343231 A was issued, an invention of Andre F. Devreux, assigned to the Compagnie Internationale de Participation et d’Investissement “Cipari” S.A., for his “Brewing Apparatus Having Sampling Means Delivering Suspension to Fermenting Vessel.” Here’s the Abstract:

A process for adjusting the amount of yeast introduced into a fermentative liquid comprises periodically taking a sample from a mass of suspended yeast maintained in movement in a closed circuit, subjecting the sample to fermentation by adding a nutrient element, and adjusting the supply of yeast to the liquid in accordance with the fermentative power of the treated yeast sample. The implementing plant comprises a container having a conical bottom containing yeast suspended in a liquid, a pipe connecting the bottom of the container to a fermentation tank, and a regulating or adjusting pump for supplying yeast from the container into the tank. A pipe for recycling the suspended yeast in the container is provided, as well as means for ensuring, during a predetermined time interval, the recycling of the suspension of yeast from the bottom of the container to the upper part thereof. Sampling means periodically extract a predetermined volume of the recycling yeast suspension and deliver it to a small fermenting vessel whereat the nutrient agent is supplied. Means are then provided for determining the fermentative power of the yeast sample and for adjusting the yeast supply of the fermentation tank in accordance therewith.