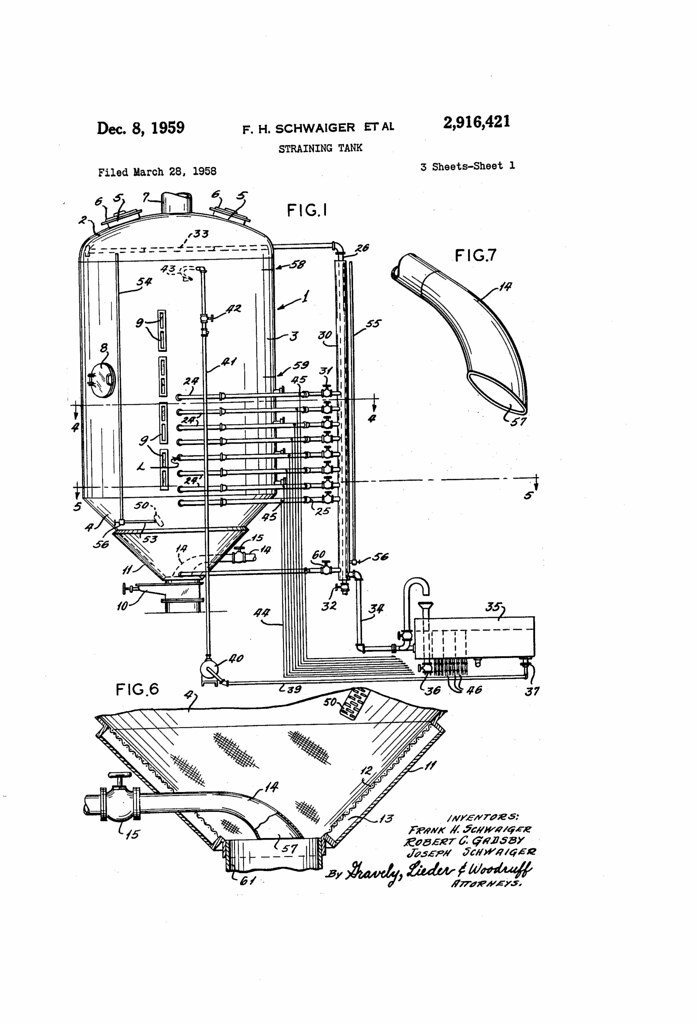

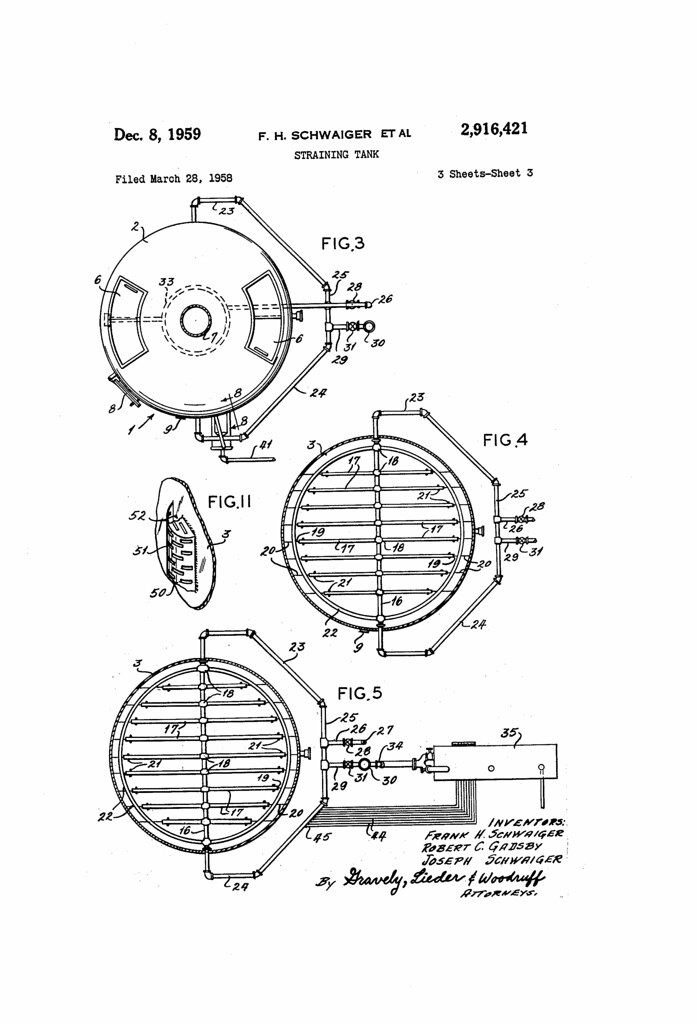

Today in 1959, US Patent 2916421 A was issued, another invention of Robert C. Gadsby, Joseph Schwaiger and Frank H. Schwaiger, assigned to Anheuser Busch, for their “Straining Tank.” There’s no Abstract, although in the description it includes this summary:

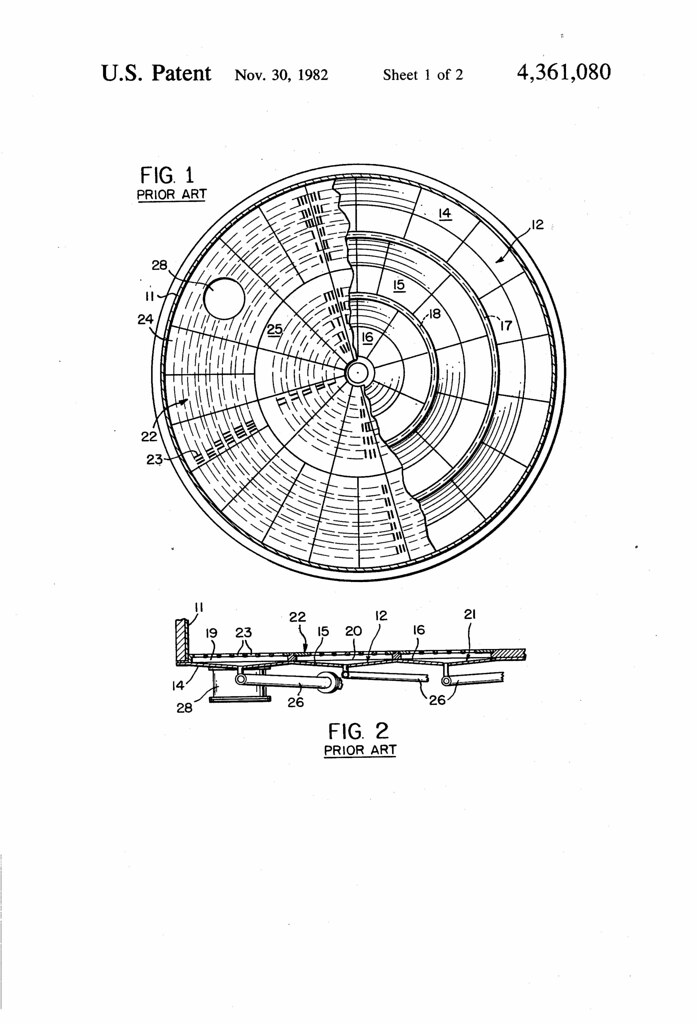

This invention relates to a straining tank or grain extractor or lauter tub, and more particularly to a new type of straining tank for use in the brewing industry to remove extract from brewers grains.

One of the principal objects of the present invention is to increase the efficiency of the extraction of soluble substances from material within a straining tank. Another object is to provide a’straining tank with the shortest exposure and contact time between the wort and grains and between the sparge water and the grains which have substances extracted therefrom, thereby extracting less of the undesired substances from the husks of the grains. This results in a cleaner and milder flavor for the resulting wort. Another object is to eliminate the mechanical agitator formerly required and avoid the formation of channels which the numerous knife .blades previously cut into the grain bed.

Another object of the present invention is to provide a straining tank which is relatively small and inexpensive compared to those lauter tubs and mash filters presently used to remove extracts from grains. Another object is to increase .the capacity for removing extracts from grains in a brewing operation, thereby increasing the capacity of the brewery. Another object is to provide a straining device which requires less time per batch and allows more brews per day. Another object is to provide for the fast removal of spent grains from a straining tank which can then be easily and rapidly cleaned.

Still another object is to provide a device which has a smaller initial cost and which requires fewer operators than previously required to efficiently operate a straining tank or mash filter.