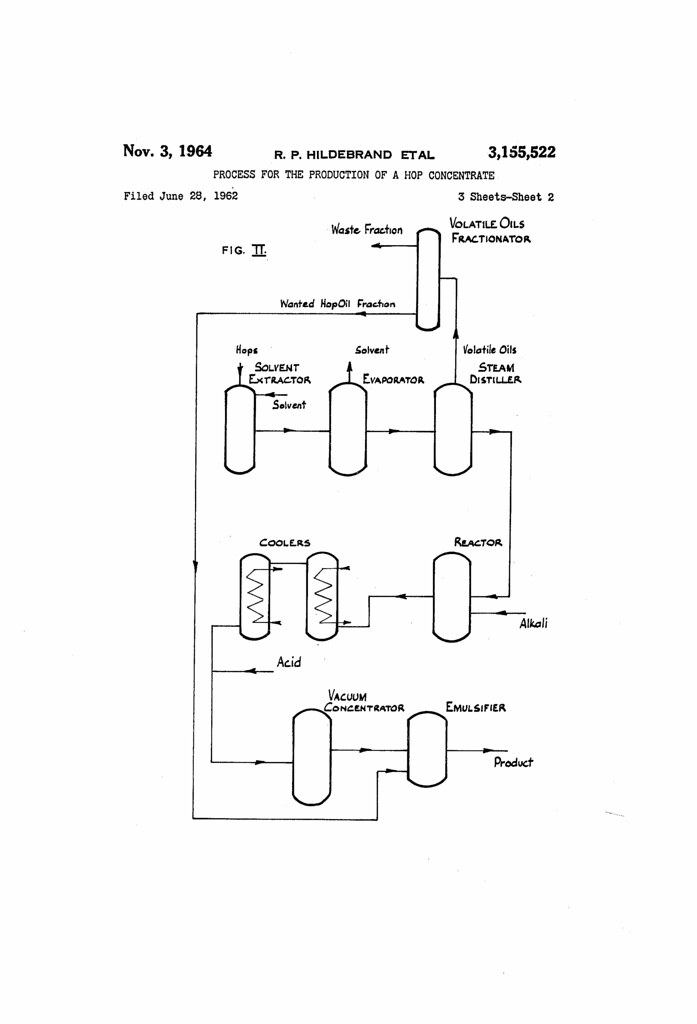

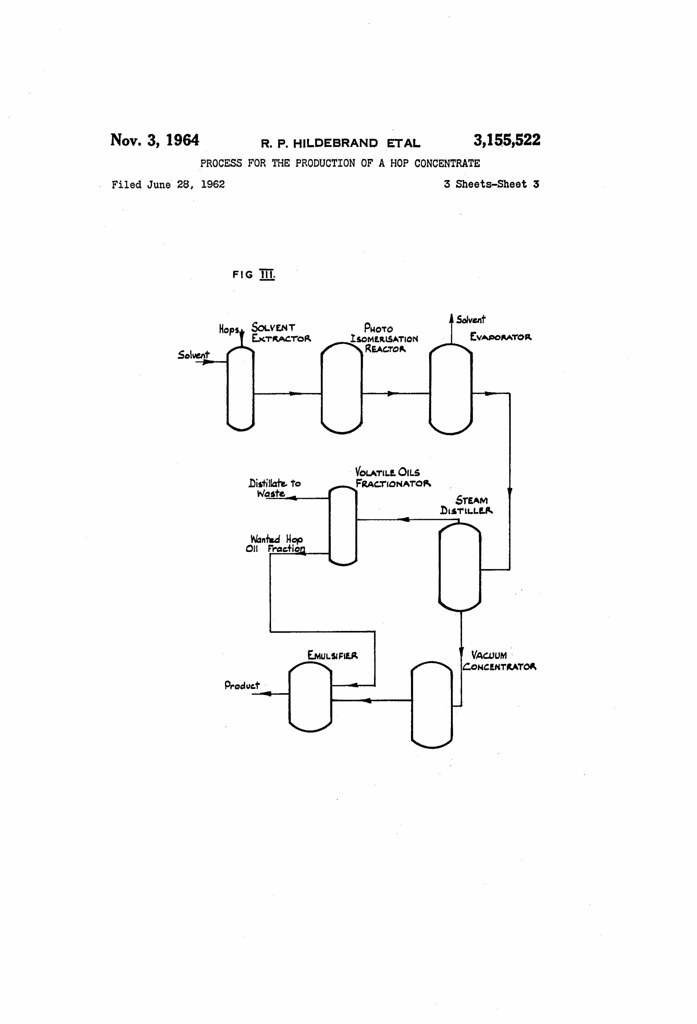

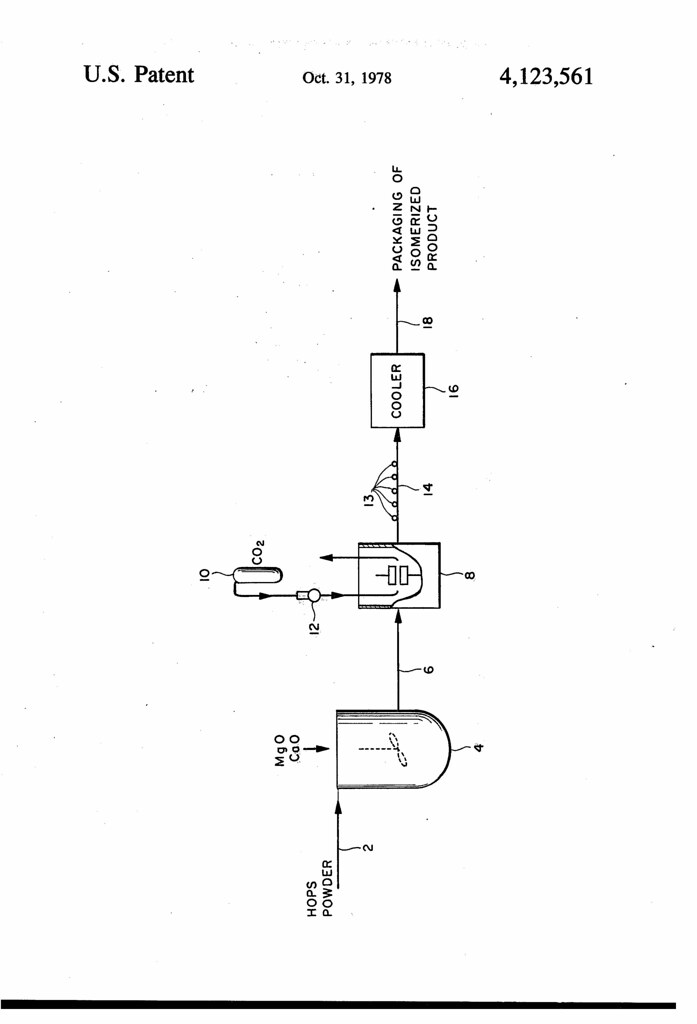

Today in 1964, US Patent 3155522 A was issued, an invention of Peter John Andrew Murray, Brian James Clarke, Robert Peter Hildebrand and Frank Vincent Harold, assigned to Carlton & United Breweries, for their “Process for the Production of a Hop Concentrate.” There’s no Abstract, although in the description it includes this summary:

This invention relates to the preparation of hop concentrates or extracts for brewing purposes, and to the production of hopped beverages, such as beer, utilizing such concentrates.

An object of this invention is to provide a new process for the manufacture of hop concentrates which if used to replace hops will impart to the finished beer in their correct balance those materials contributing to taste characteristics and flavour which are normally found in beer manufactured by conventional processes. A further object is to enable economies to be effected in the manufacture of beer or like beverages.

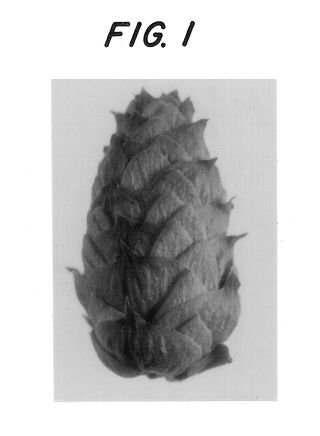

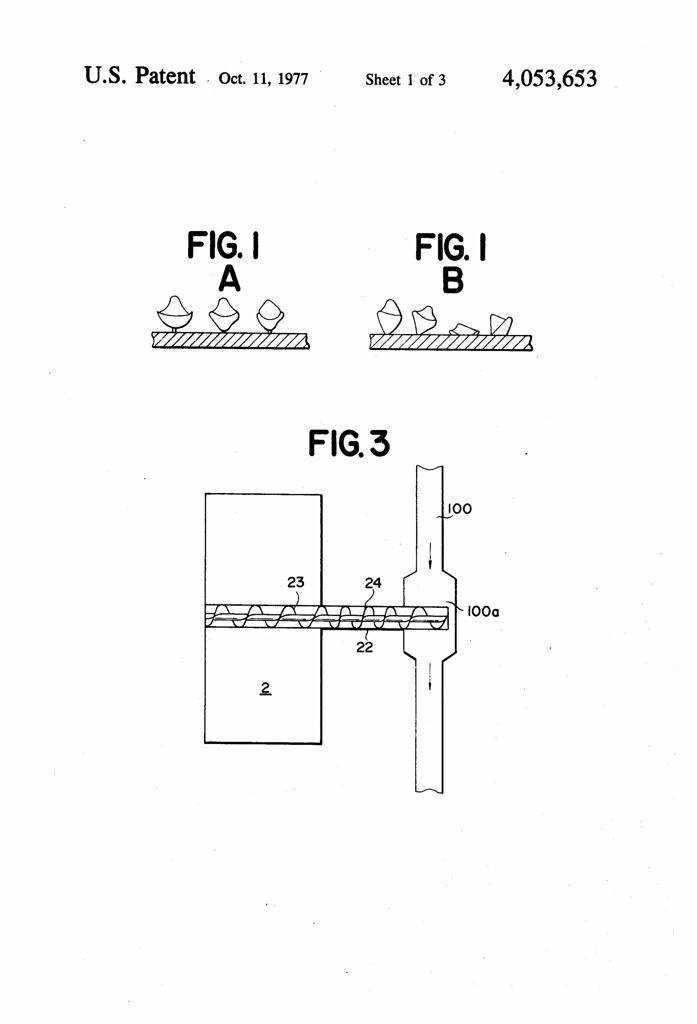

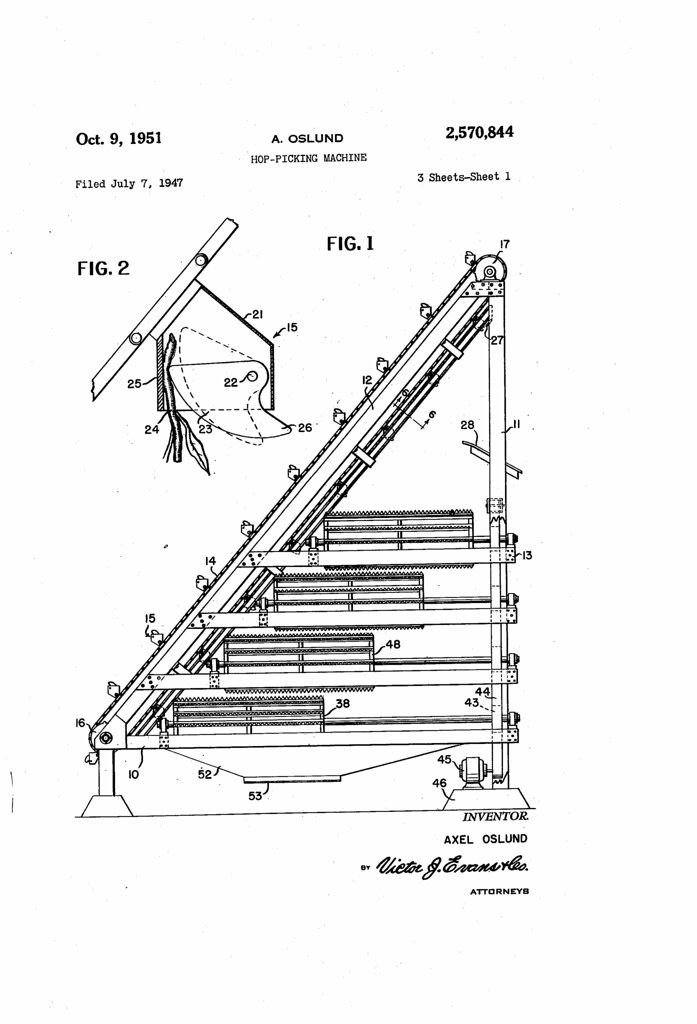

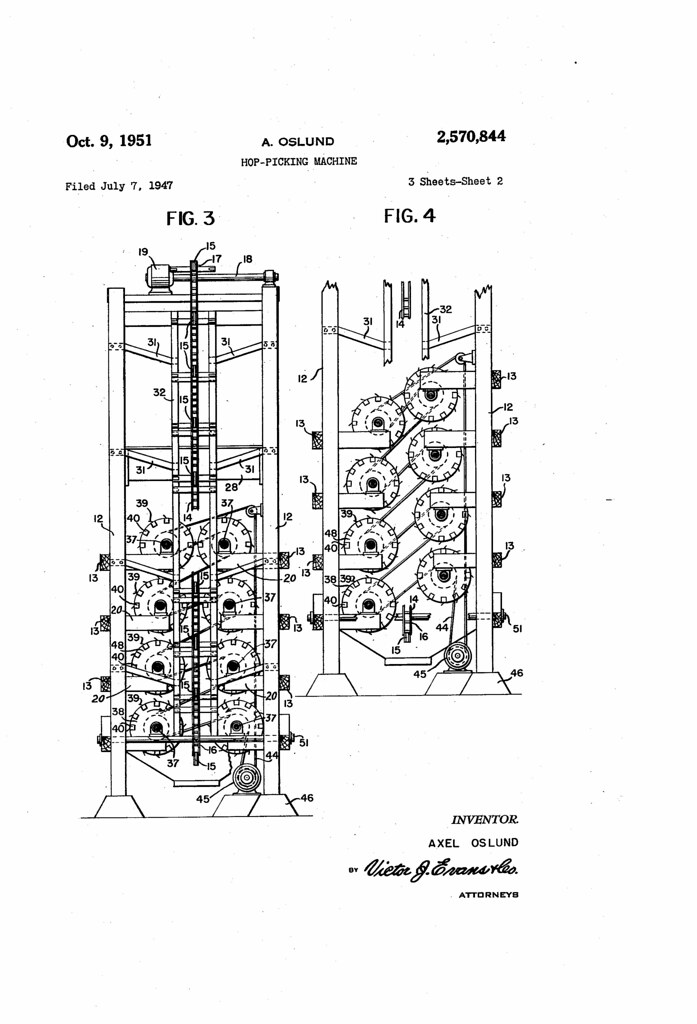

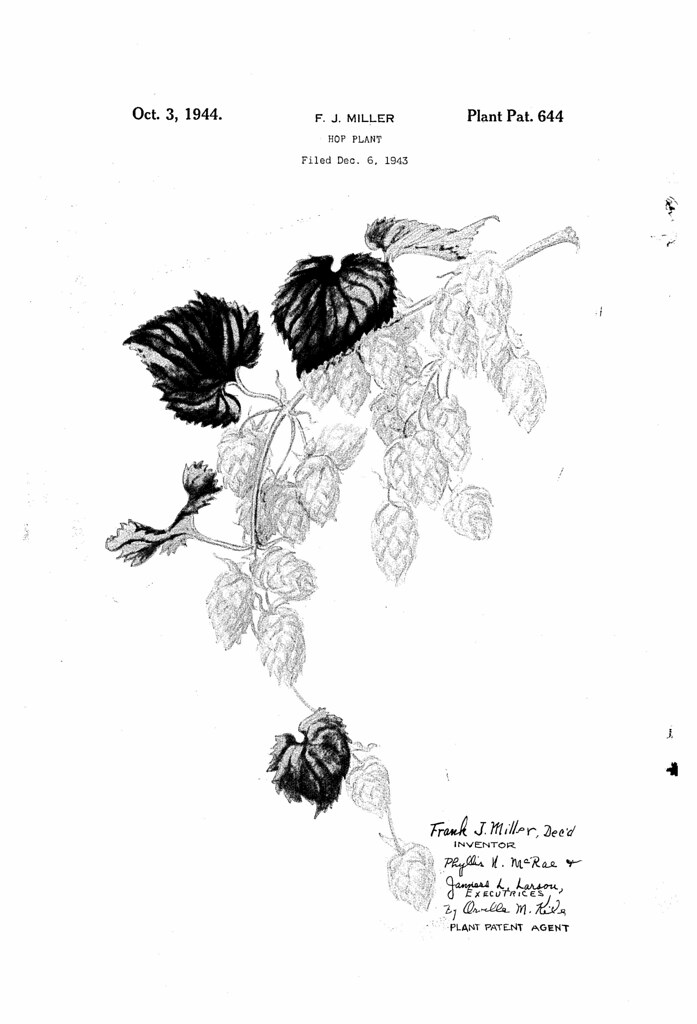

While the invention applies to the treatment of any part of the hop plant it refers in particular to the hop cones, and the hops used may be either in the freshly picked state or dried as in normal commercial practice.