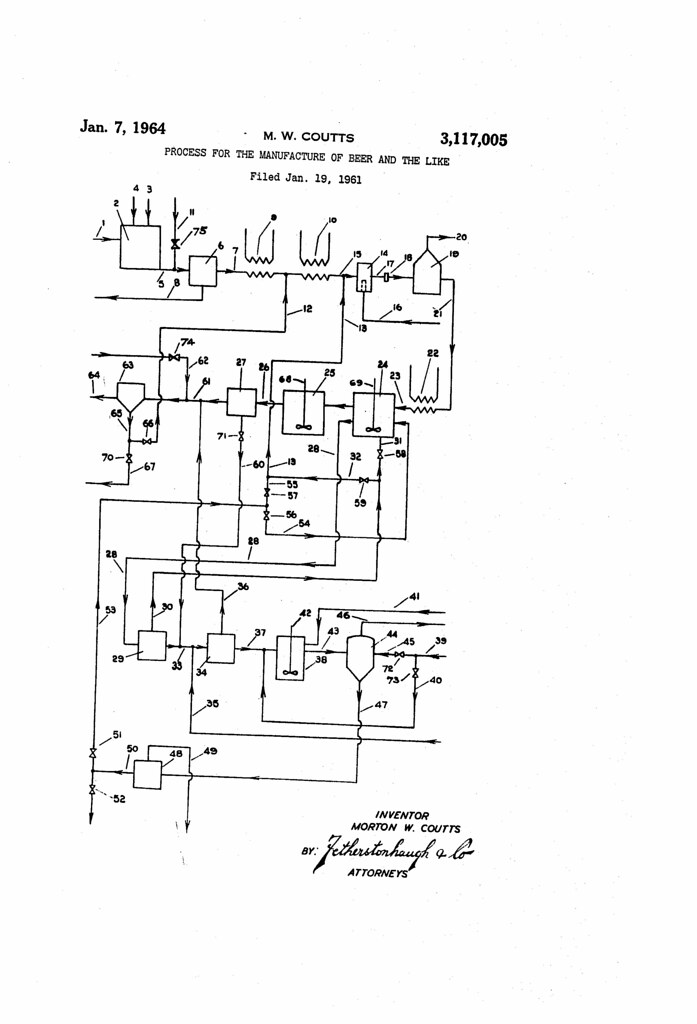

Today in 2013, US Patent 8348086 B2 was issued, an invention of Klaus-Karl Wasmuht and Cornelia Folz, assigned to Krones Ag, for their “Brewing Process and Brewery Installations.” Here’s the Abstract:

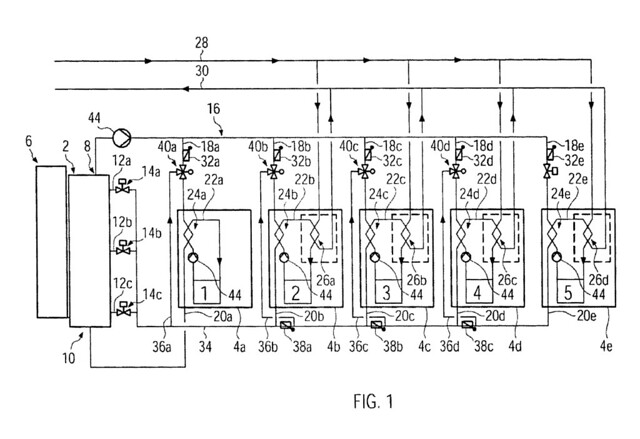

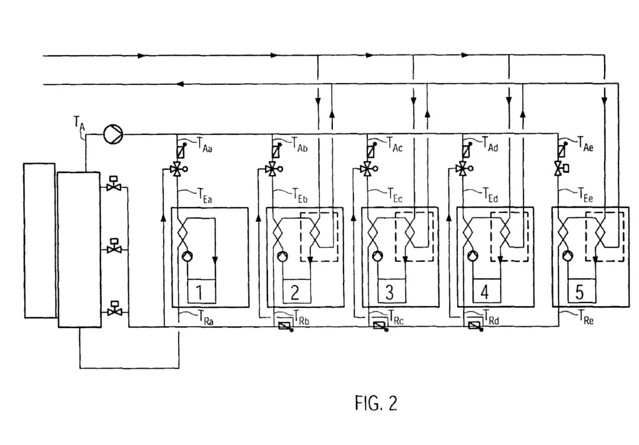

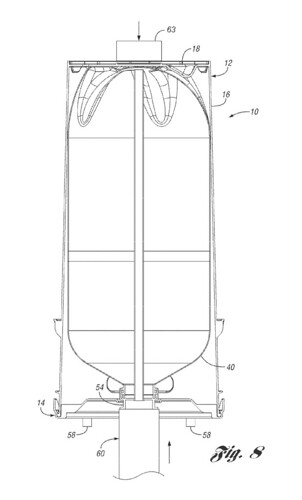

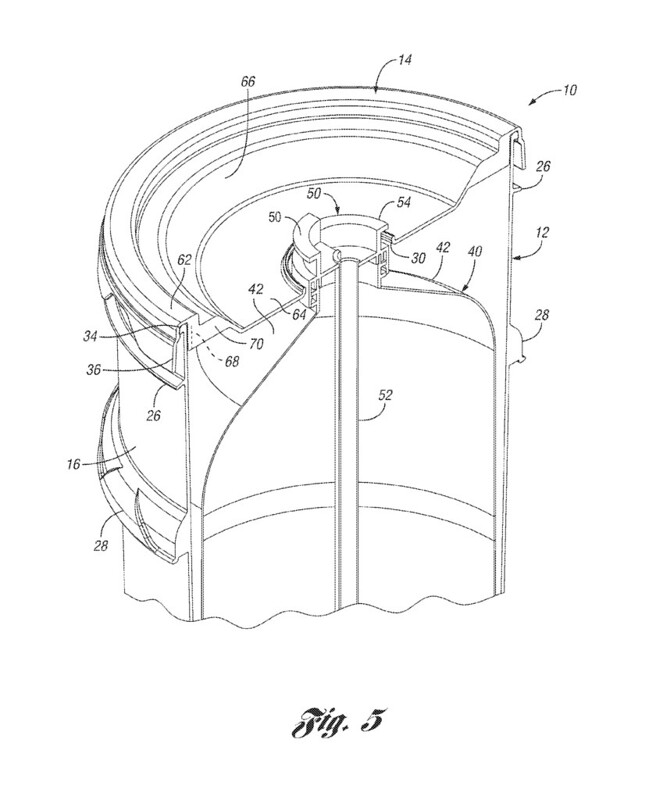

A brewing process including taking off a fluid having a starting temperature from a heat store; feeding the fluid to a plurality of heat consumers for releasing heat; and returning to the heat store the fluid which has a final temperature. The brewery installation has a heat store for controlling the flow of the fluid in the installation, and a plurality of heat consumers each of which is connected to the primary circuit for releasing heat. Improved efficiency is achieved in part by the final temperature of the fluid which flows out of the respective heat consumers is measured and the return of the fluid is controlled as a function of the measured final temperature.