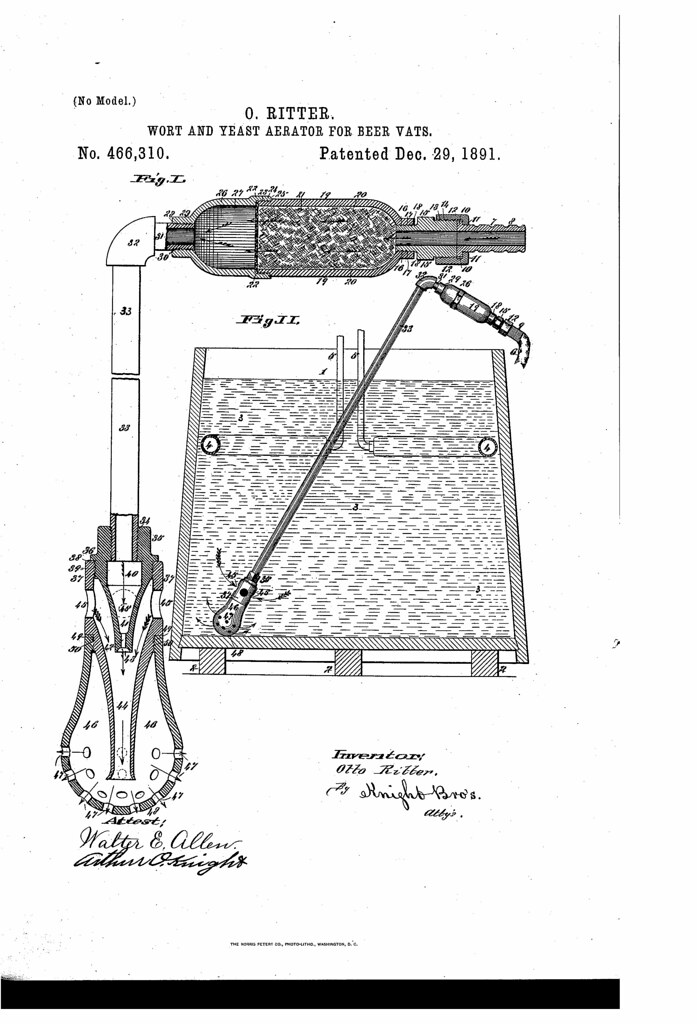

Today in 1891, US Patent 466310 A was issued, an invention of Otto Hitter, for his “Wort and Yeast Aerator For Beer Vats.” There’s no Abstract, although in the description it includes this summary:

I have invented a-certain new and useful Improvement in Wort and Yeast Aerators for Beer Vats, of which the following is a full, clear, and exact description, reference being had to the accompanying drawings, forming part of this specification.

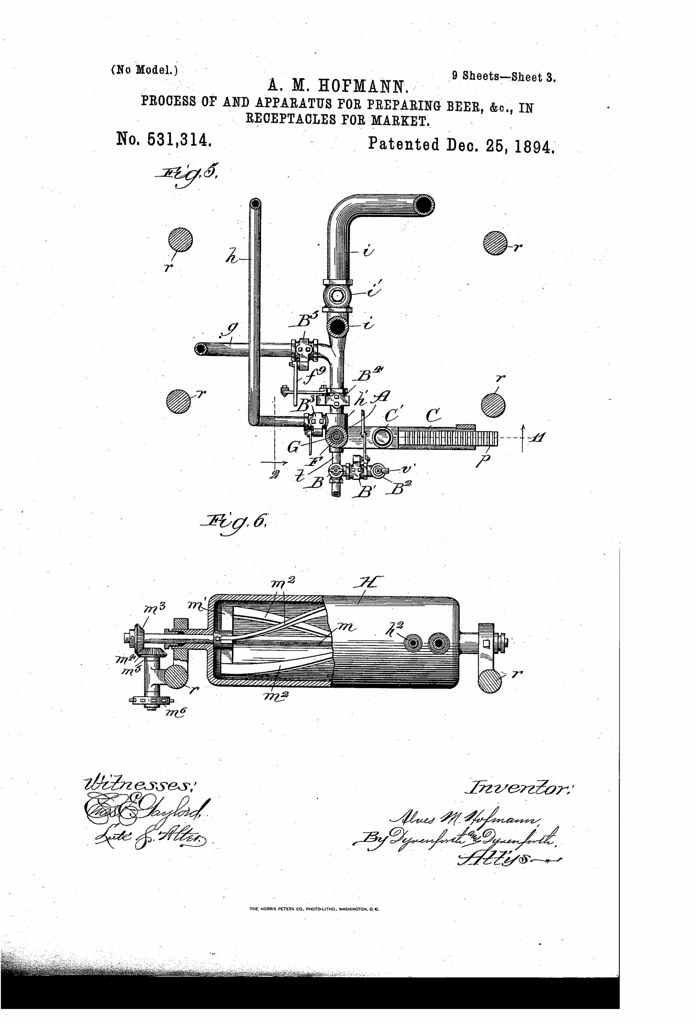

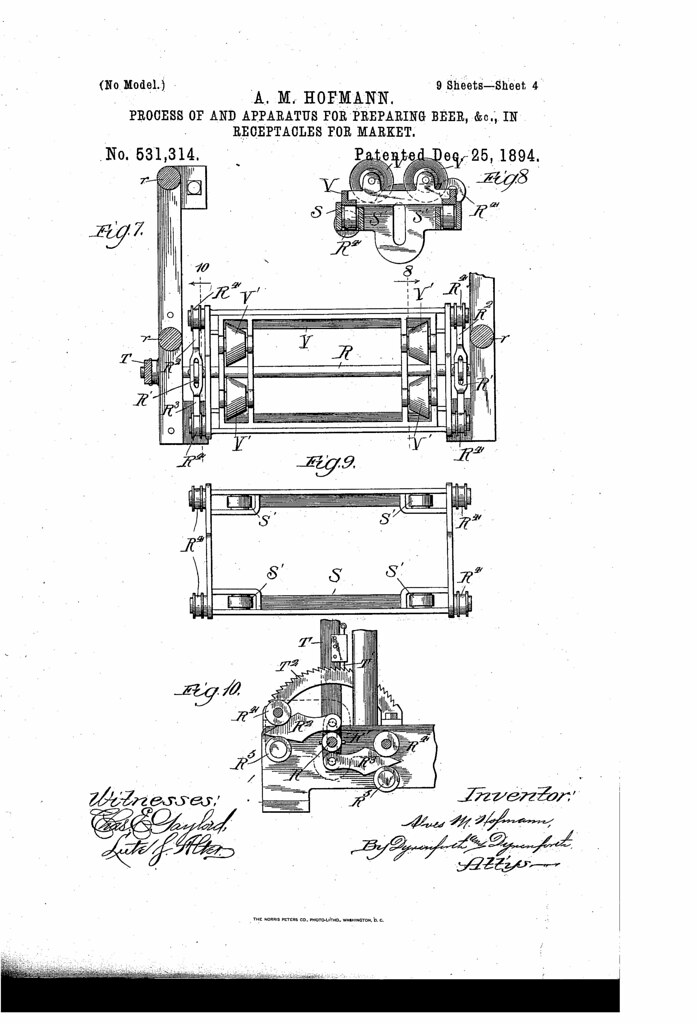

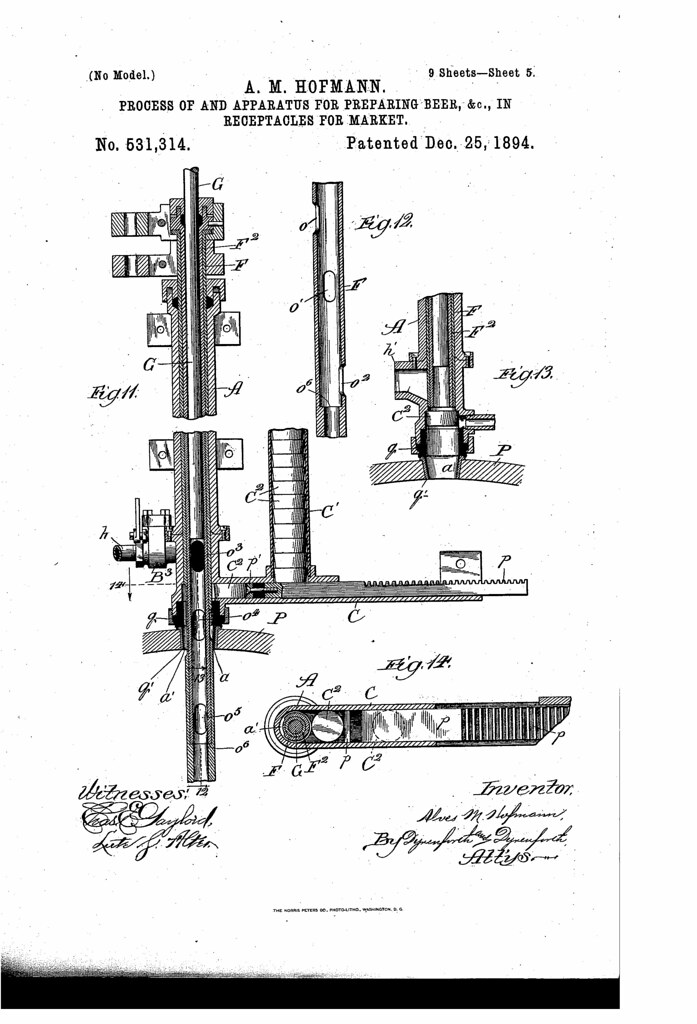

This apparatus is constructed and arranged consists in features of novelty hereinafter fully described, and pointed out in the claims. Figure I isa detail view of the aerator and shows the coupling for the air-hose, the air filter, the bulb-casing of which later forms a handle or hold for the operator, by which he directs the instrument. It also shows the inception filtered air-chamber, the supply air tube, and the compound aerating-bulb; and Fig. II is a vertical section of a brewers fermenting vat and shows the yeast and wort aerator in active operation therein.