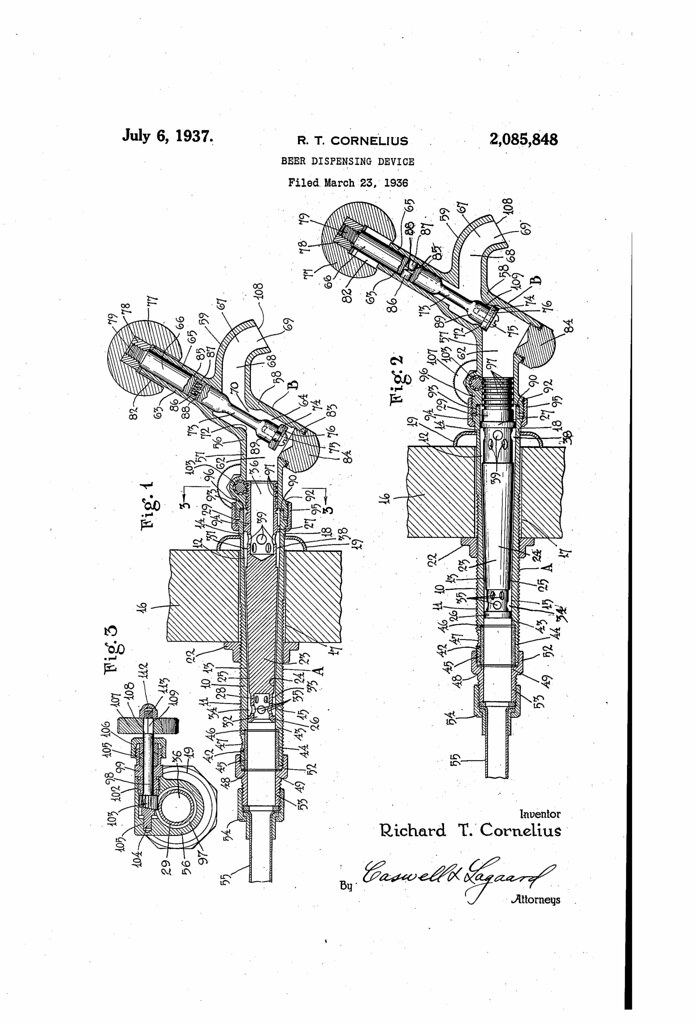

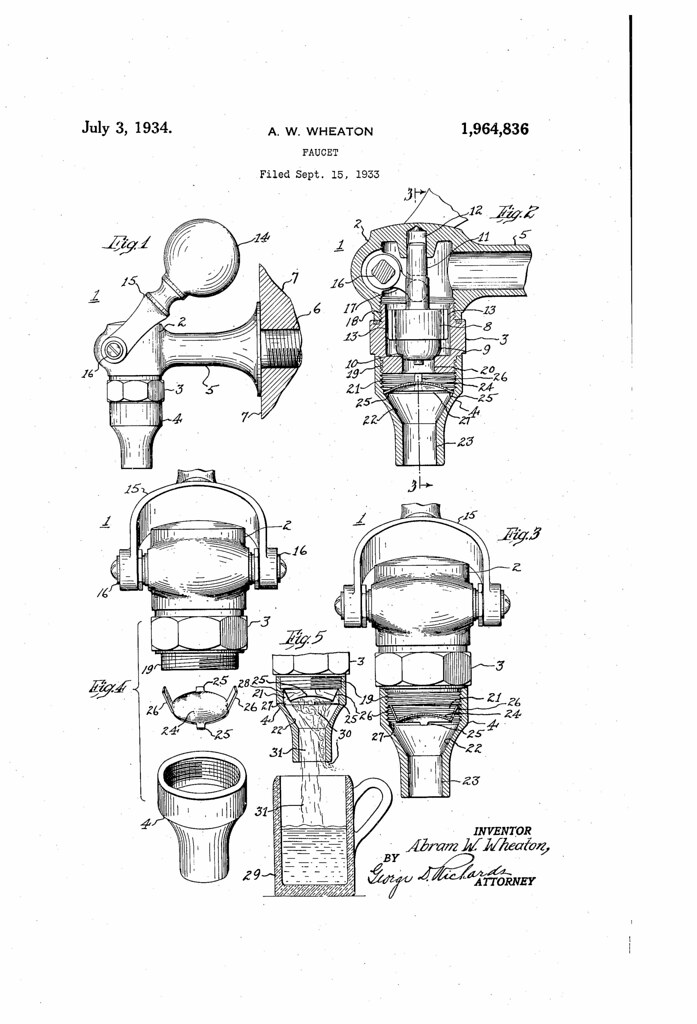

Today in 1937, US Patent 2085848 A was issued, an invention of Richard T. Cornelius, for his “Beer Dispensing Device.” There’s no Abstract, although in the description it includes this summary:

My invention relates to beer dispensing devices and has for an object to provide a device by means of which beer may be drawn in a manner to procure the desired amount of foam or collar on the beer when discharged into any type of drinking vessel.

Another object of the invention resides in providing a device in which the amount of foam produced can be varied.

An object of the invention resides in providing a dispensing device including a flow regulating device and a faucet and in which the rate of flow can be adjusted independently of the operation of the faucet.