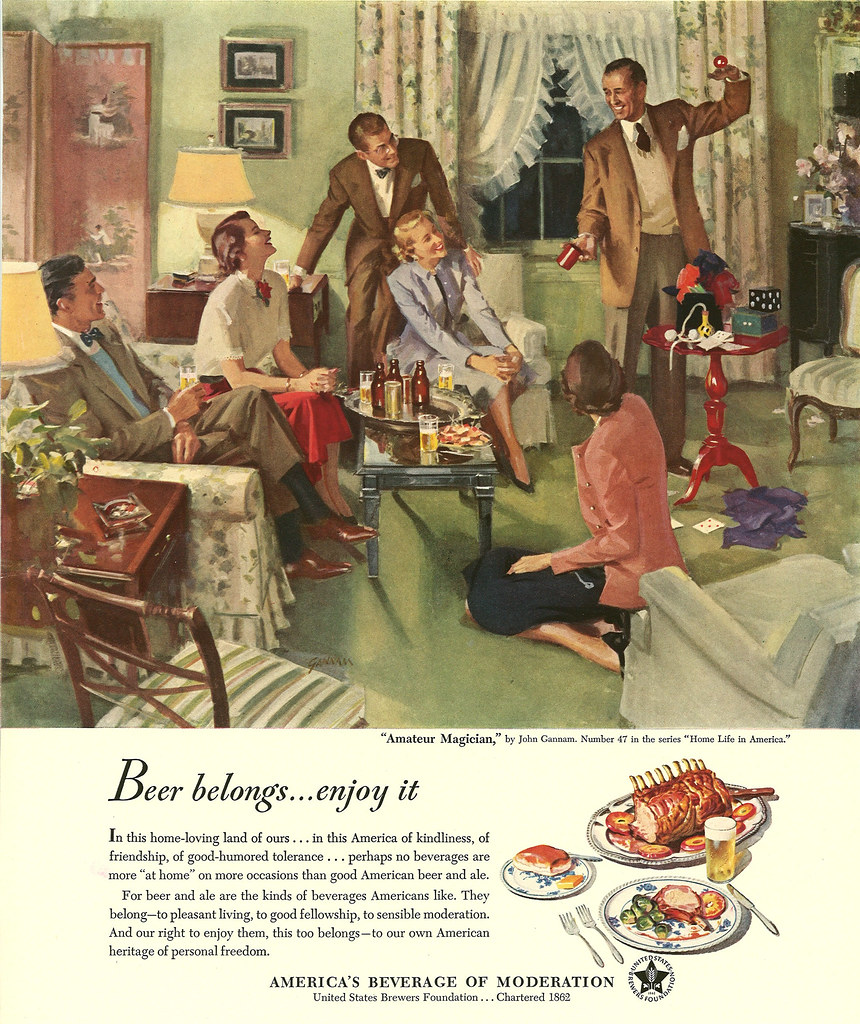

Saturday’s ad is entitled Thanksgiving Dinner, and the illustration was done in 1950 by Douglass Crockwell. It’s #49 in a series entitled “Home Life in America,” also known as the Beer Belongs series of ads that the United States Brewers Foundation ran from 1945 to 1956. In this ad, a picture perfect Thanksgiving turkey is on the dinner table, but the it’s not complete. People wait in the wings to be seated until the most important job is done. The matriarch of the family is putting beer glasses down at each place setting, the final touch, before the holiday meal can begin. Just like at my house. If that text, and the art, looks familiar, you’ve got a good memory as this exact same Thanksgiving Dinner piece was used in 1947 as #10 in the series.