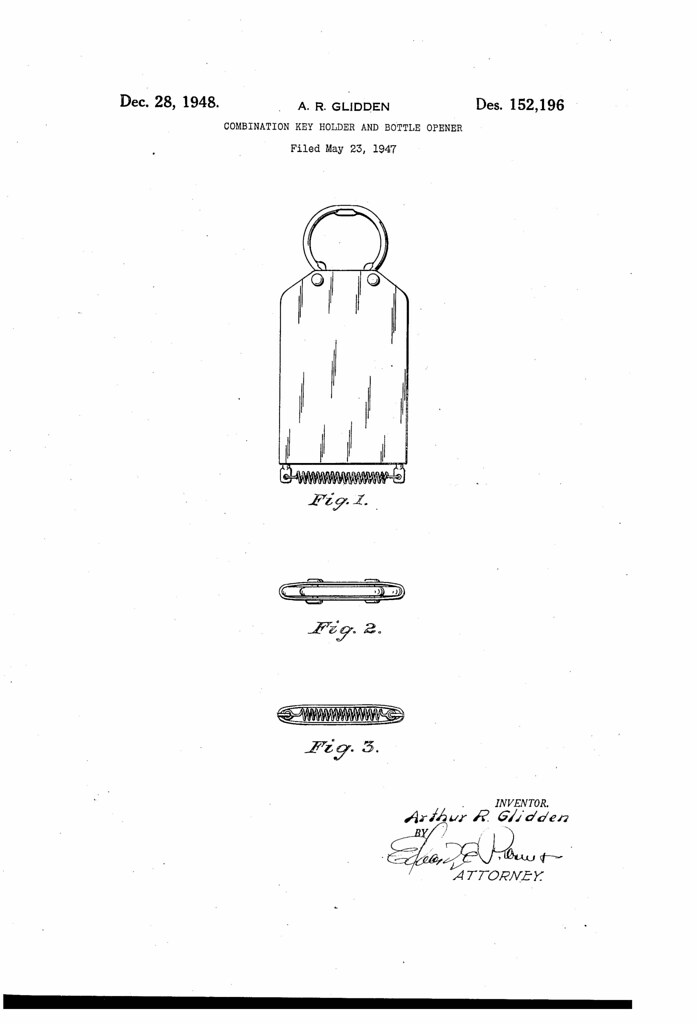

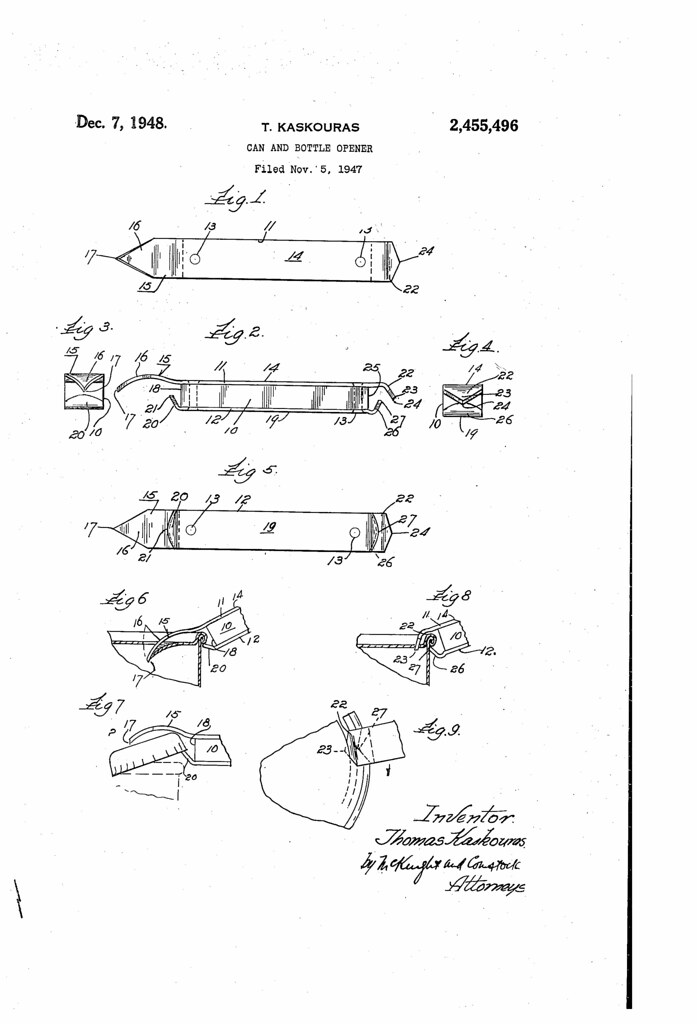

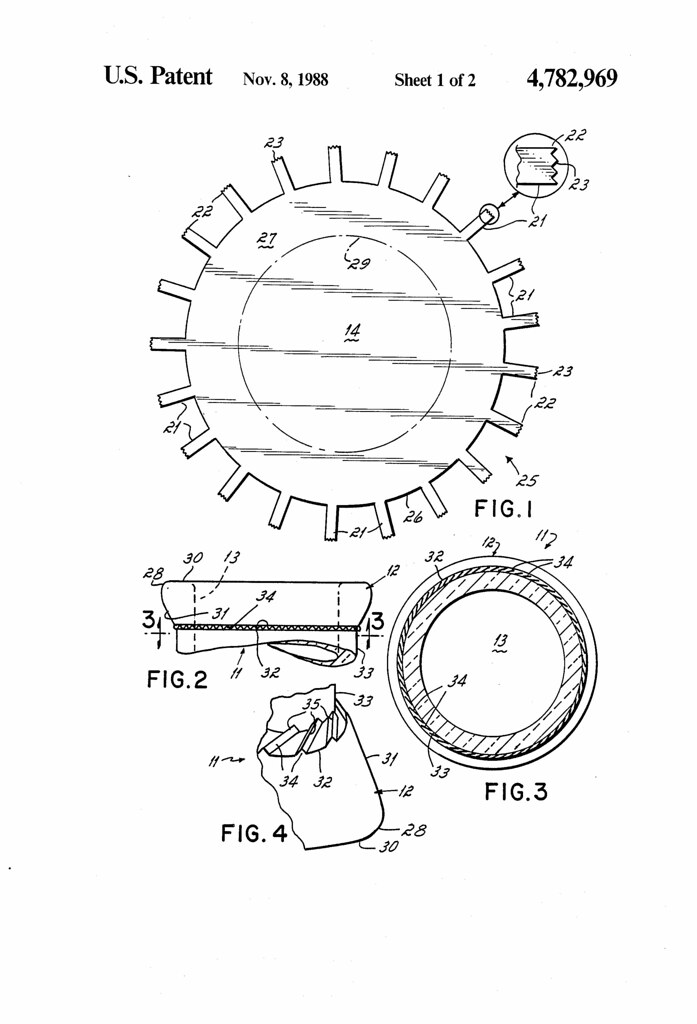

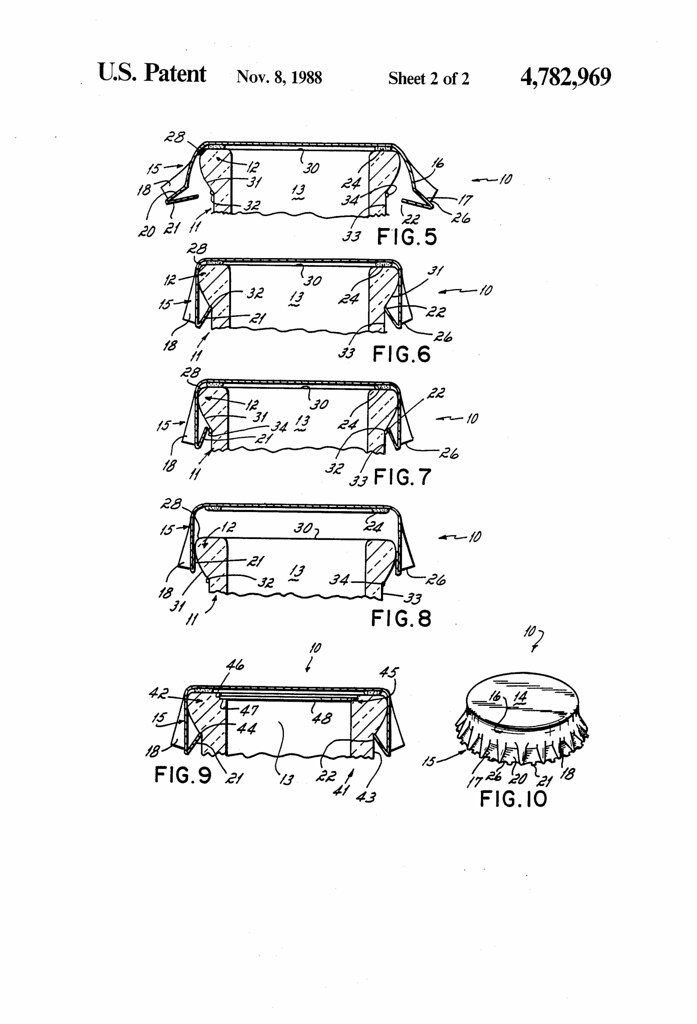

Today in 1948, US Patent D152196 S was issued, an invention of Arthur R. Glidden, for his “Design For a Combination Key Holder and Bottle Opener.” There’s no Abstract, although in the description it includes this summary:

I have invented a new, original, and ornamental Design for a Combination Key Holder and Bottle Opener, of which the following is a specification, reference being had to the accompanying drawing, forming a part thereof.