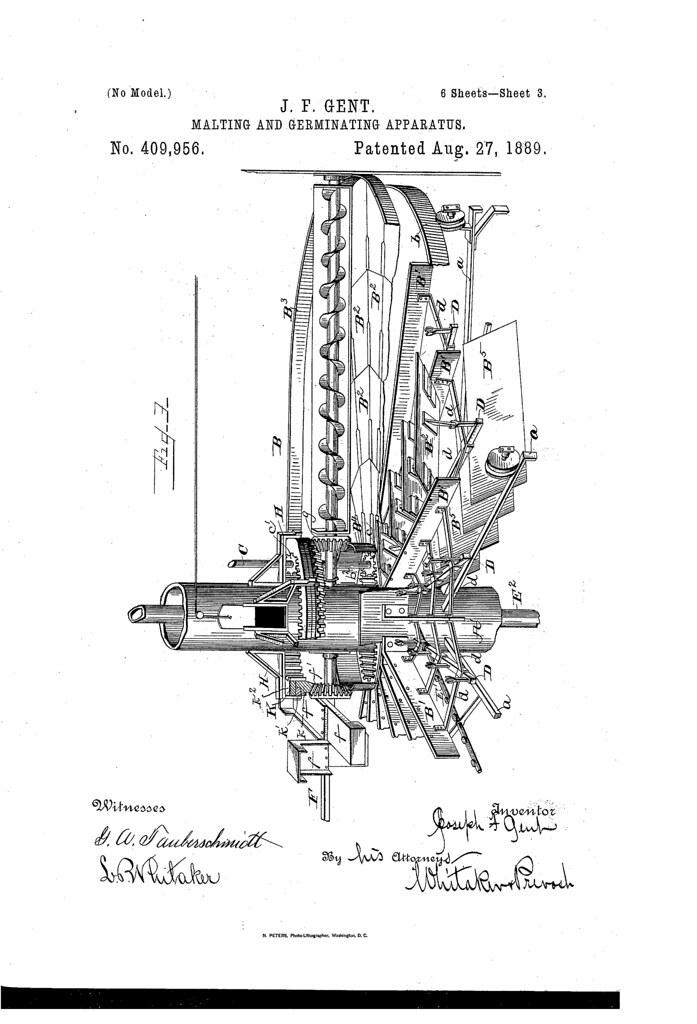

Today in 1961, US Patent 2998351 A was issued, an invention of Noel Keir, Frederick Richard Graesser, Wilbert E. Stoddart and Douglas L. Thompson, assigned to Dominion Malting Ontario Ltd., for their “Process for the Continuous Malting of Grain.” There’s no Abstract, although in the description it includes this summary:

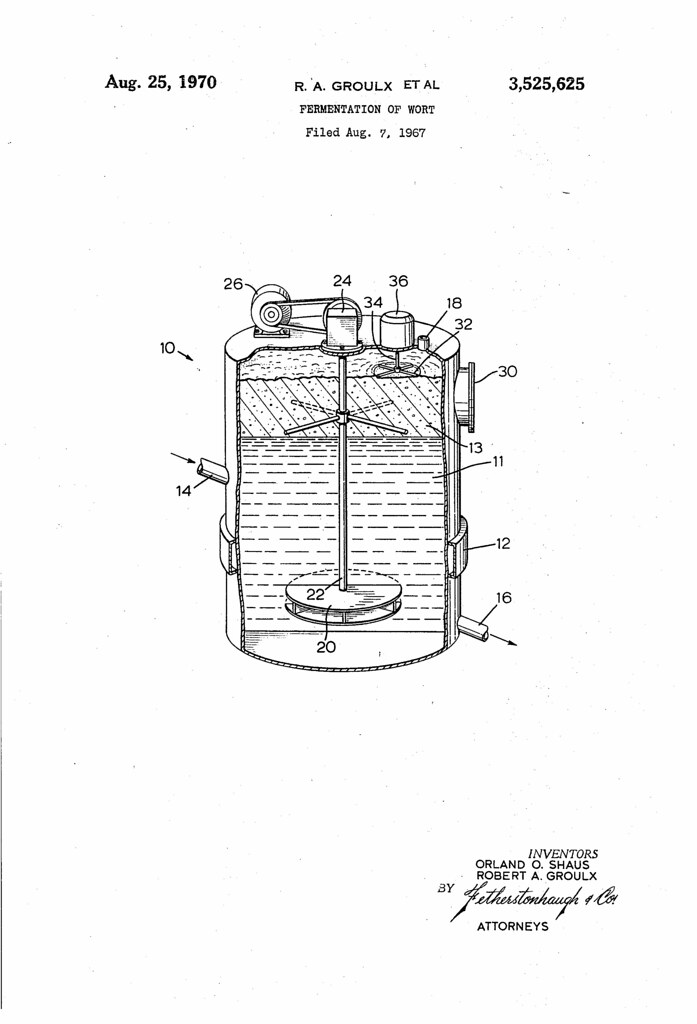

The present invention avoids most of the disadvantages of the prior art and provides for simple continuous processing through which not only complication is avoided but the processing may be reduced to a period of three days or less in comparison with approximately ten days or more, and is subject to minute control which has been difficult in prior batch processes. In fact the present continuous process provides for continuous processing through stages or zones maintaining constant conditions, varied as to one another, according to requirements necessary in regard to the character of the grain, and through which the grain continuously passes in effect to provide the continuous yield of a substantially uniform malt. Moreover, other attendant advantages result as labour required per unit of production will be reduced, resulting in greater economy, the weight and strength of complete equipment will be reduced and initial costs of buildings thus lessened; whereas the process provides for an extremely wide range of control as to time and processing, moisture content and temperature gradient, so that the conditions of manufacture may be adapted to the quality and type of grain being processed as to provide for the production of malt of superior quality and of generally uniform character in which all factors of production have been closely controlled throughout.

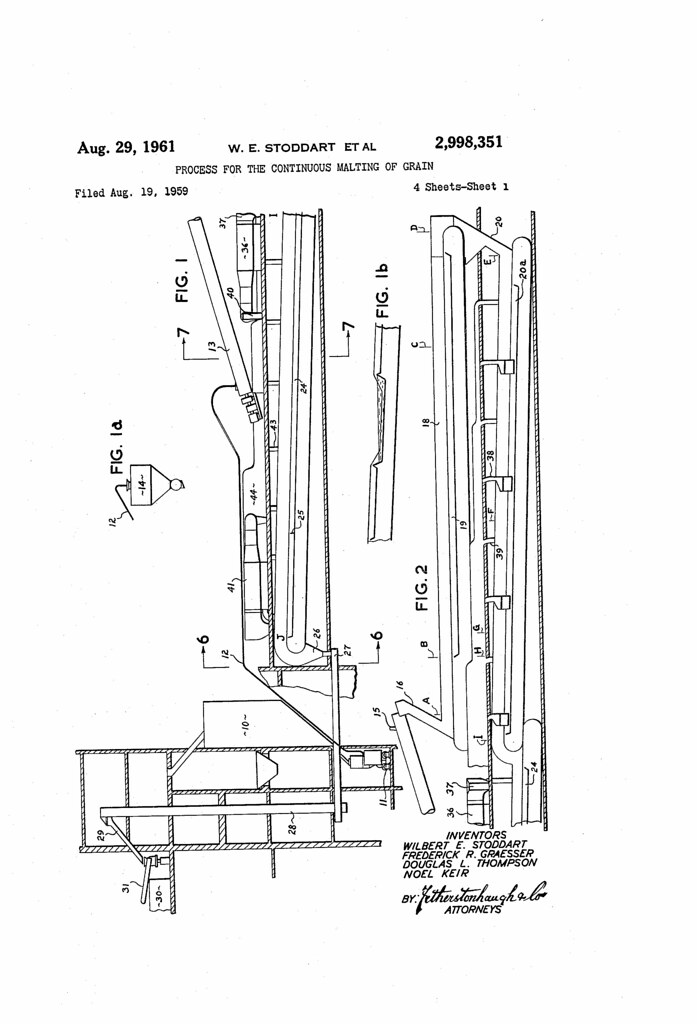

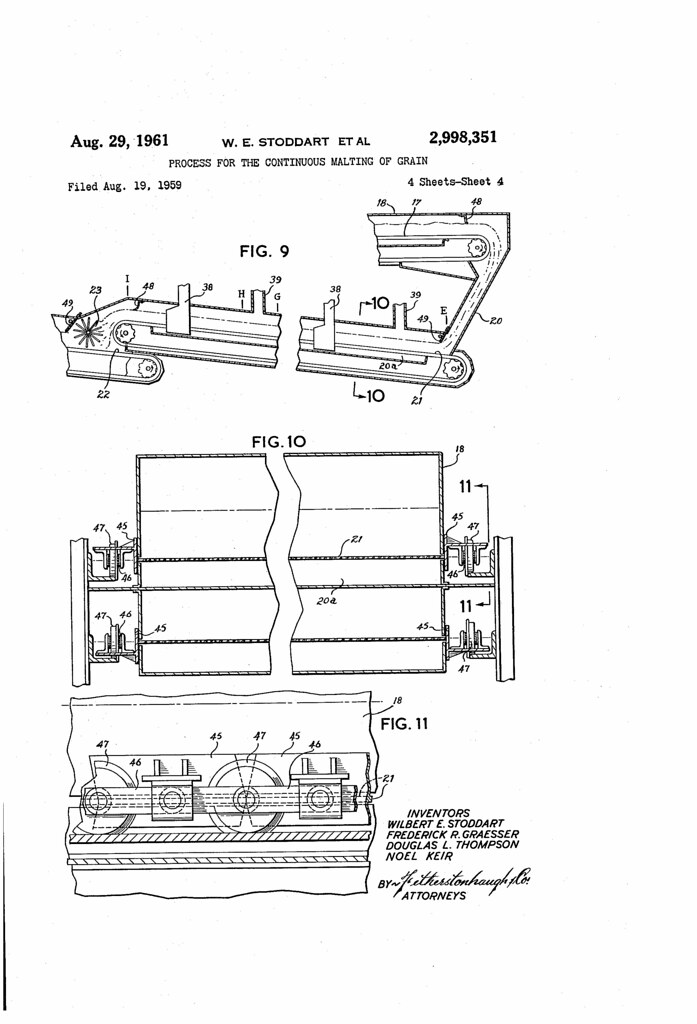

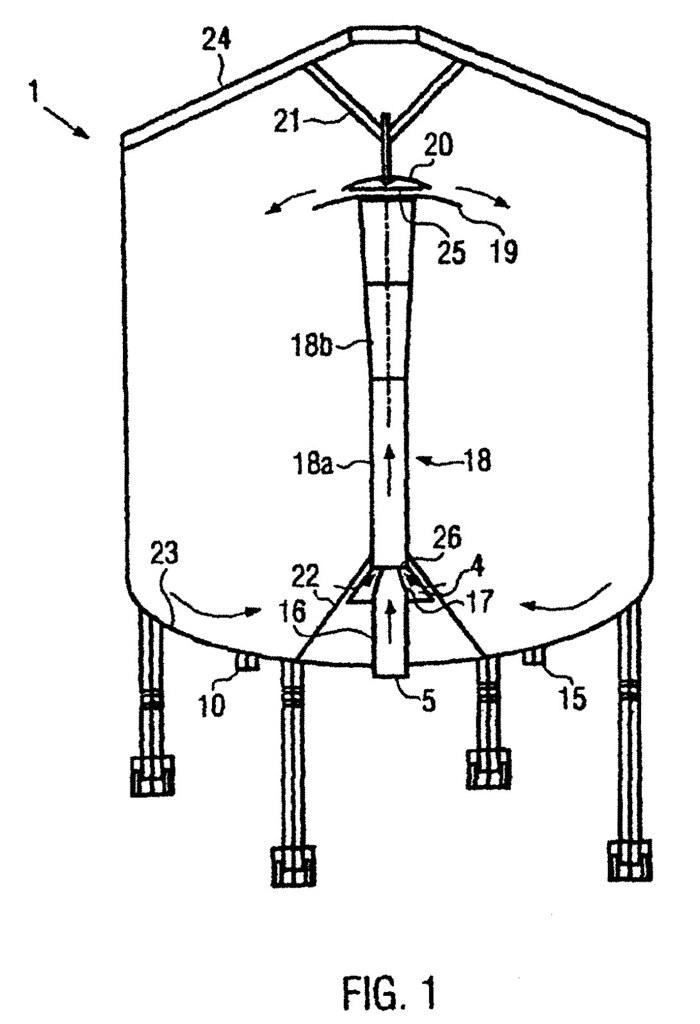

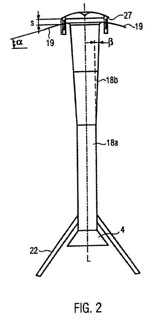

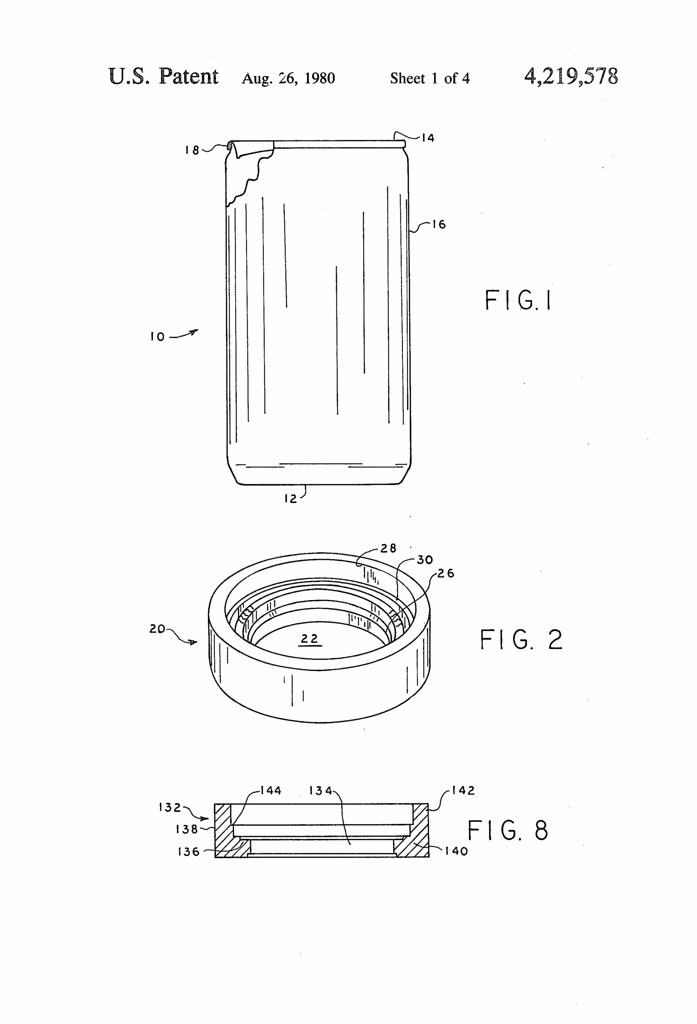

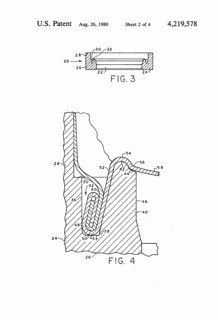

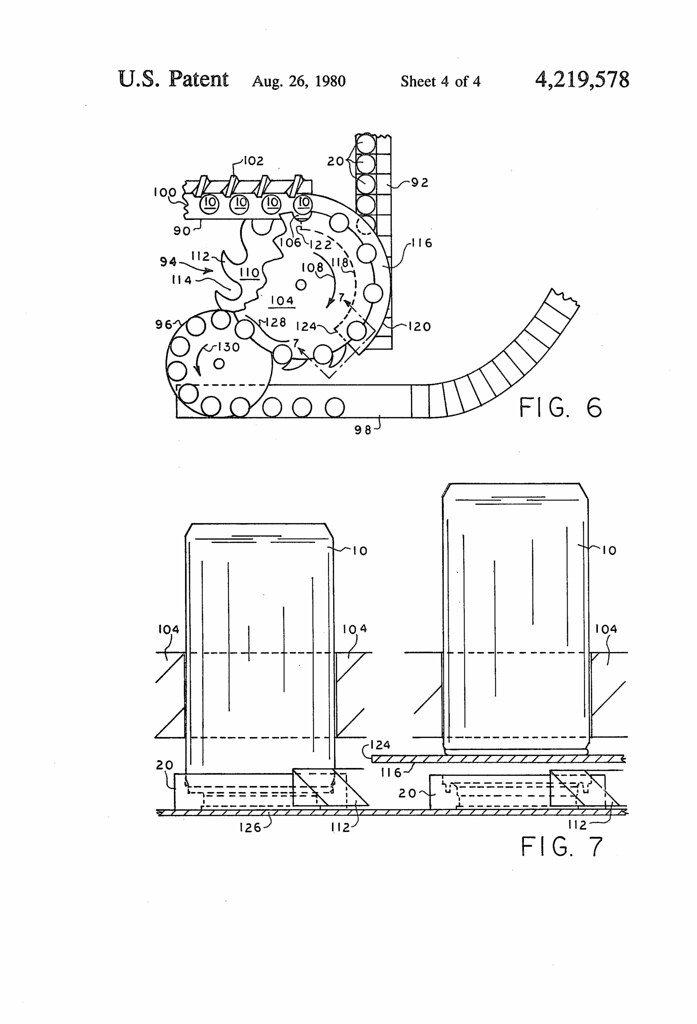

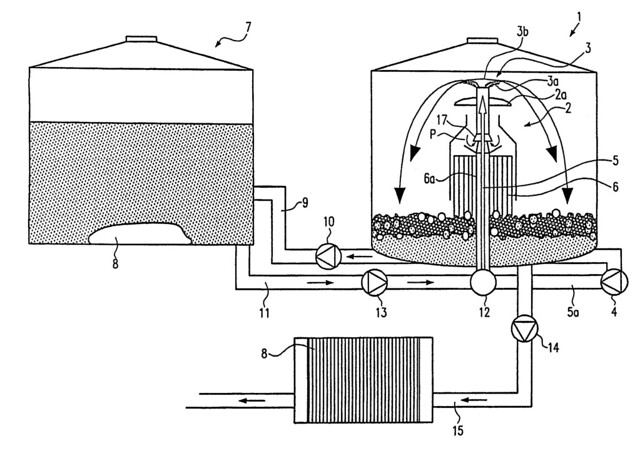

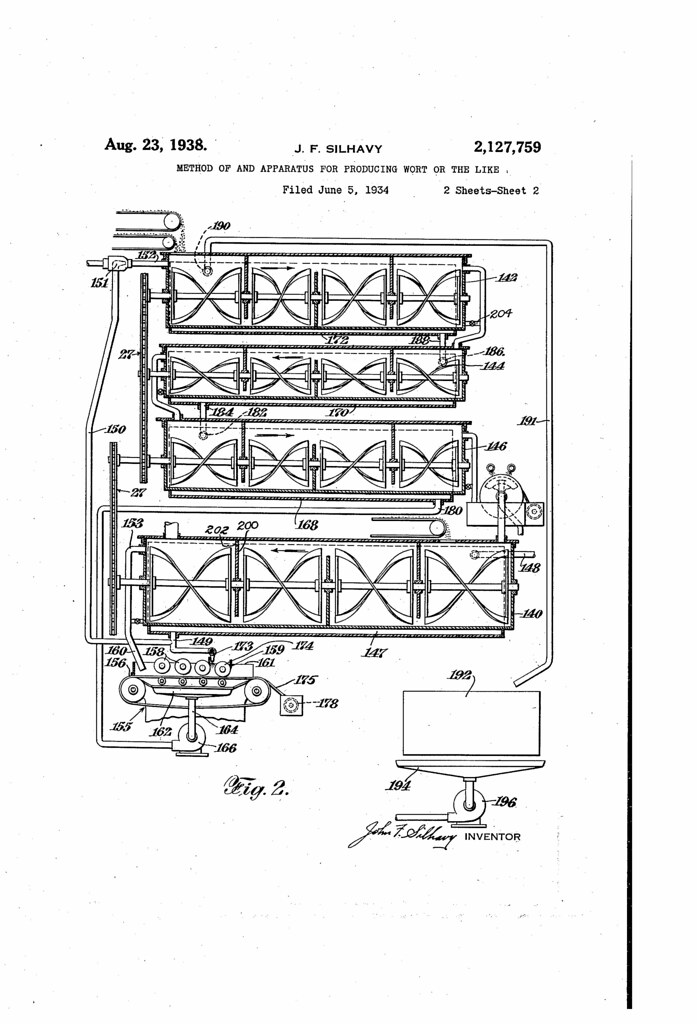

The invention generally embodies the steps of continuously forming and moving a bed of grain in a predetermined path, subjecting said moving grain bed to intermittent periods of water spray and periods of rest and periods of humid aeration at temperatures between 50 and 100 F., and finally moving said bed through a drying zone at elevated temperatures. Preferably the processing includes in said steps a period of drenching the bed followed by dry aeration. The grain may be introduced to the processing steps in any suitable manner, such as by pumping it together with water to the point of preliminary processing, which may start with the dispersing of the grain in water, and allowing the sound grain to settle, while the lighter grain and low gravity extraneous material may be continuously removed from the surface of the water body in which it is dispersed and delivered to a suitable recovery unit.