Today in 1997, US Patent 5667832 A was issued, an invention of Keith Tromans, assigned to Scottish And Newcastle Plc, for his “Method and Device for Foam Generation by Dispersion of Bubbles.” Here’s the Abstract:

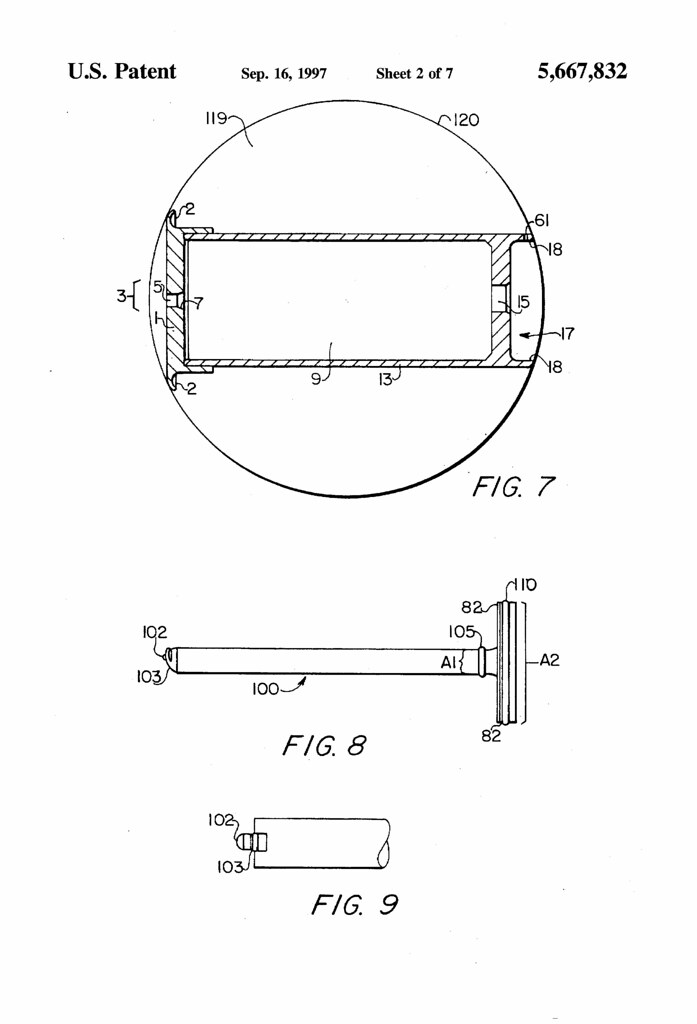

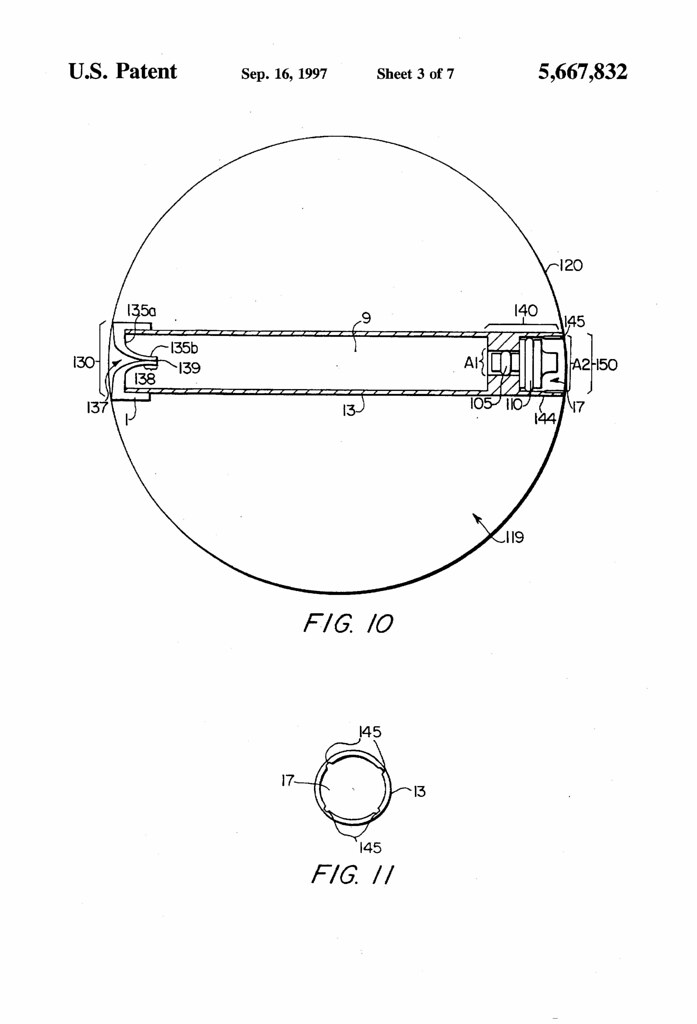

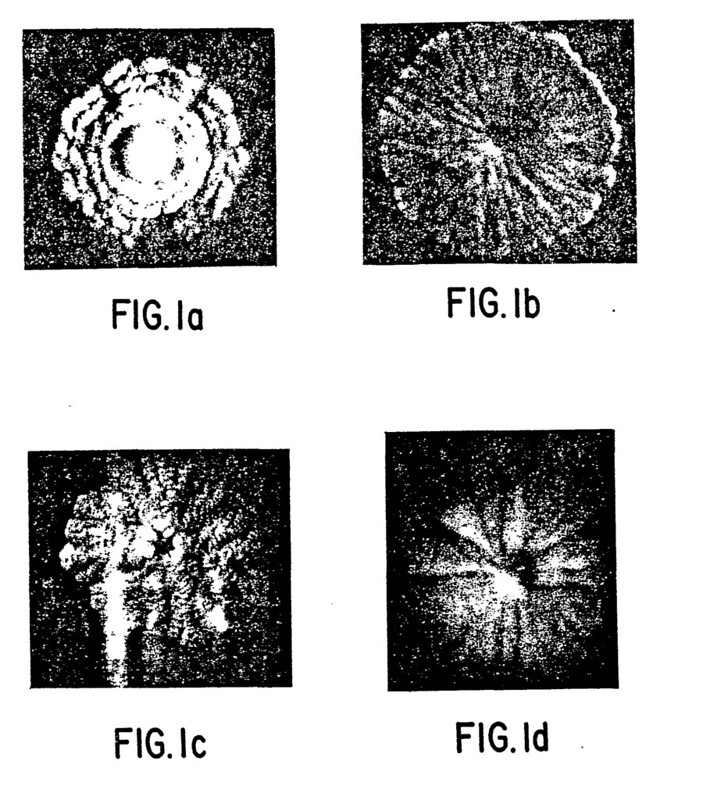

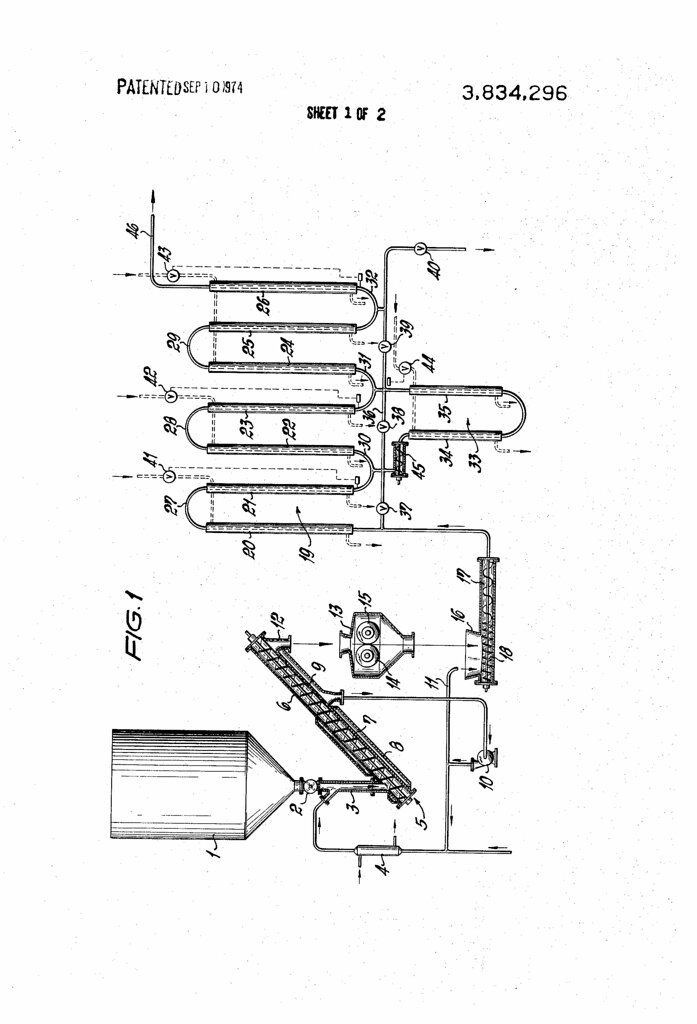

A method and apparatus for the generation of a foaming dispersion of bubbles in a carbonated beverage or other gas-containing liquid packaged in a can (120) or other sealed container. An initially liquid-free device (9) having an internal chamber with an inlet/outlet valve (130/150) assembly is placed in the can, which is then filled with the beverage. The can is sealed and pasteurized, which raises the internal pressure in the can to force some of the gasified beverage into the device through the inlet valve. The outlet valve holds the quantity of beverage in the internal chamber until the can is opened, whereupon the depressurization of the can opens the outlet valve to discharge the internal chamber through an orifice to initiate seed bubbles which form a head on the beverage. The method and apparatus are particularly applicable to producing a head on fermented alcoholic beverages to simulate draught beverages.