Today in 1985, US Patent D533739 S1 was issued, an invention of Jochen-Heiner Dipl-In Keilbach, assigned to Eichbaum Brauereien Ag, for his “Process for Energy Recovery in Beer Wort Boiling.” Here’s the Abstract:

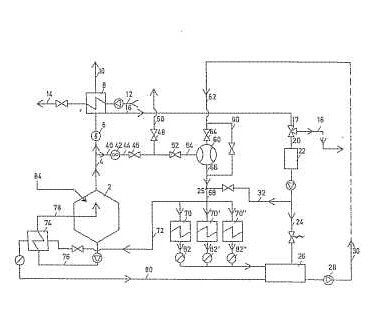

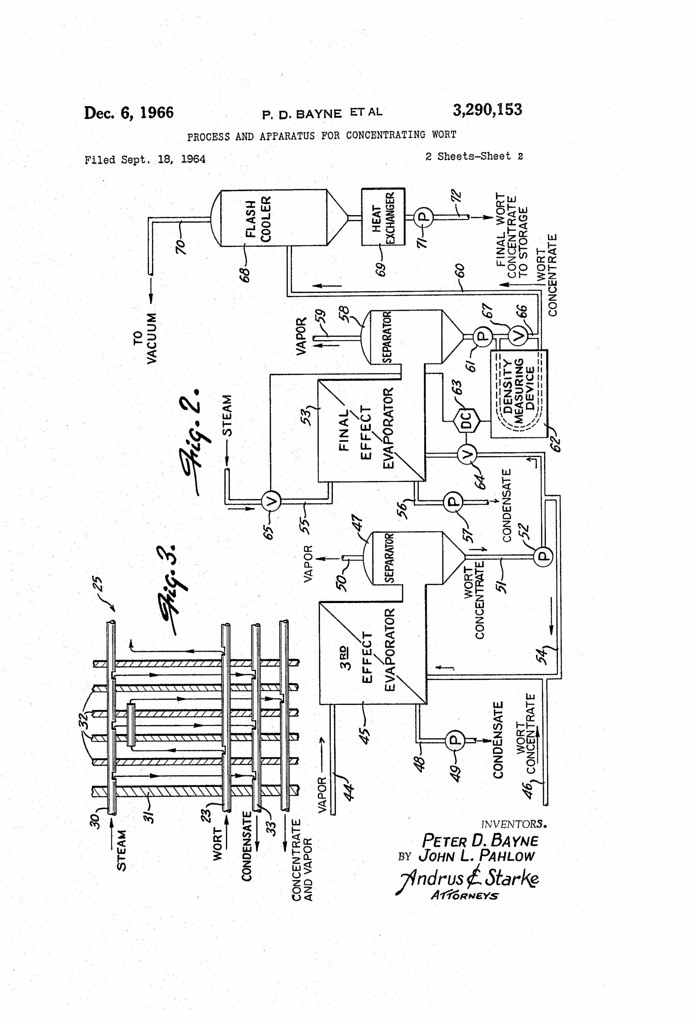

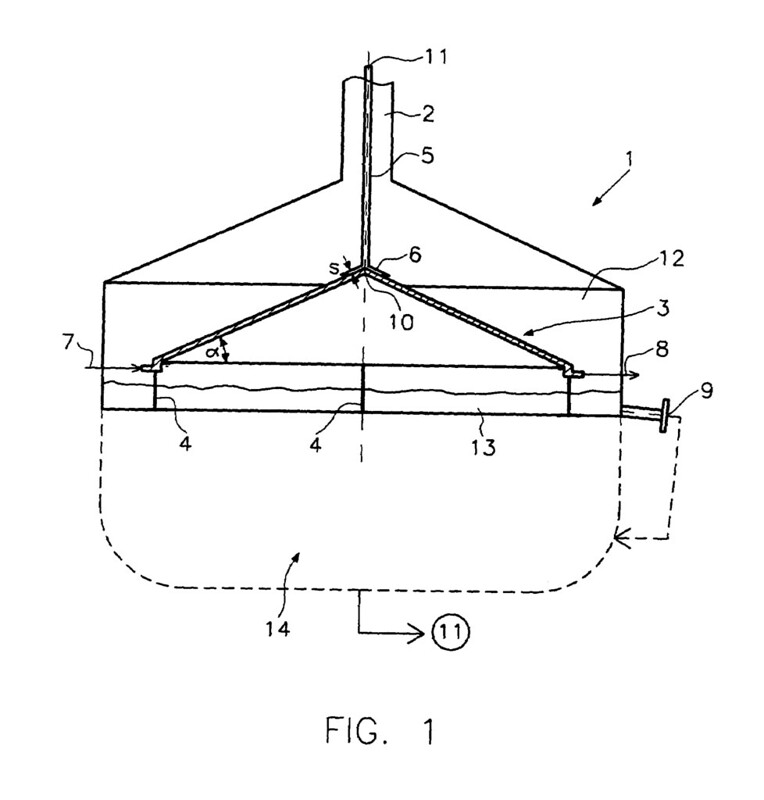

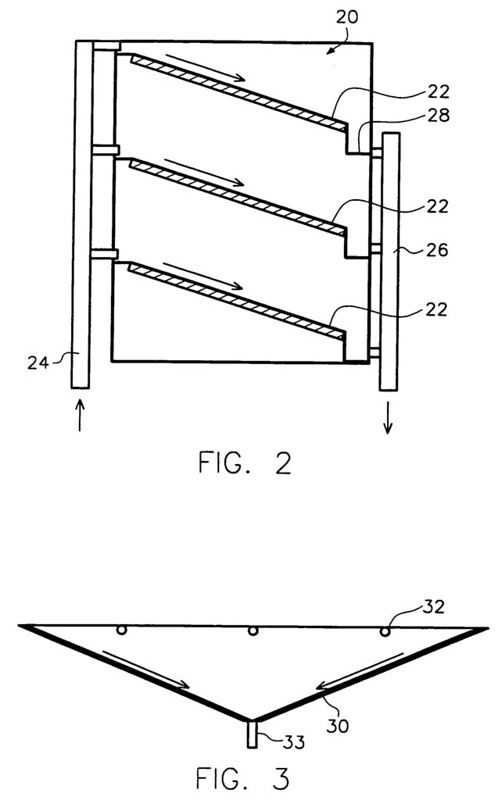

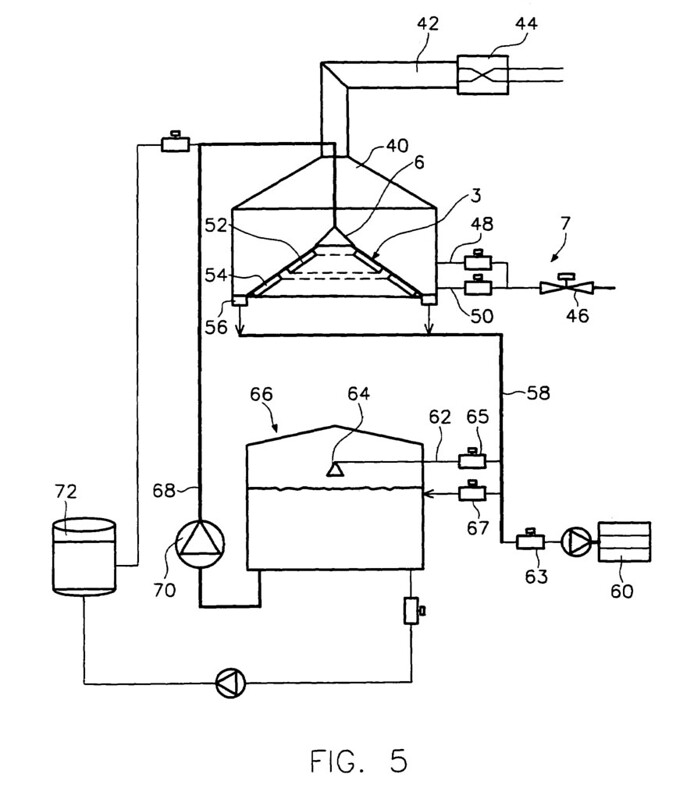

The invention relates to a process for energy recovery in beer wort boiling by condensation of the vapours on heat exchangers, which is characterised in that, in a start-up phase, the vapours are conducted away virtually unpressurised via a copper vapour condenser (8), and the hop residue-containing condensate is discarded, whereupon in the main phase, part of the hop residue-free vapours is withdrawn virtually unpressurised with the exclusion of air using a steam jet pump (60) fed with superheated steam or saturated steam and condensed via further heat exchangers (70, 70′, 70”, 74) and fed to the steam circulation together with the condensate, likewise no longer containing hop residues, by the copper vapour condenser (8).