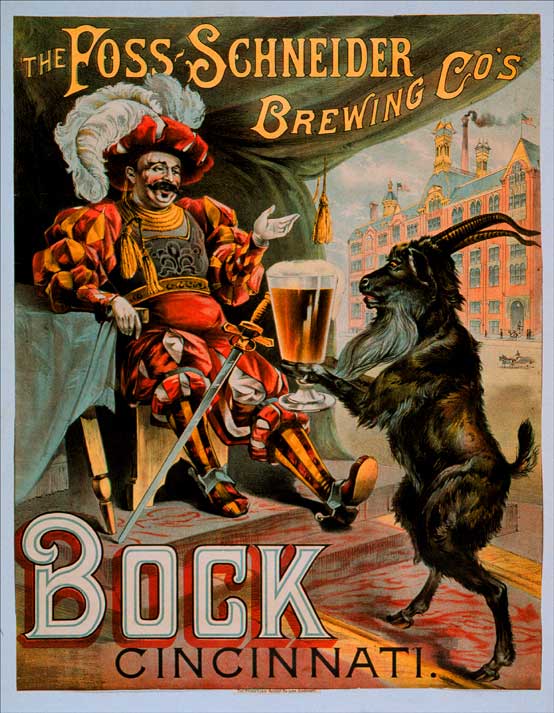

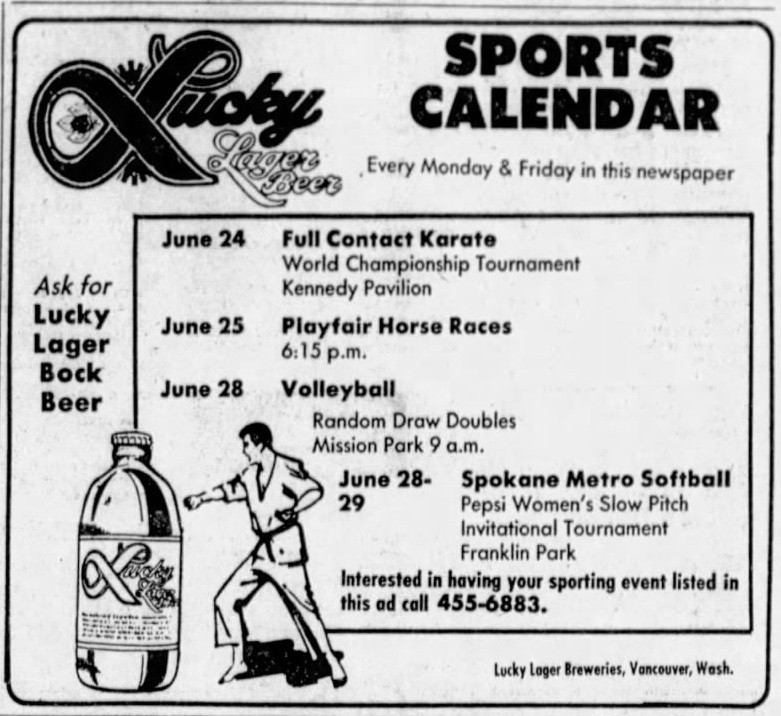

Last year I decided to concentrate on Bock ads. Bock, of course, may have originated in Germany, in the town of Einbeck. Because many 19th century American breweries were founded by German immigrants, they offered a bock at certain times of the year, be it Spring, Easter, Lent, Christmas, or what have you. In a sense they were some of the first seasonal beers. “The style was later adopted in Bavaria by Munich brewers in the 17th century. Due to their Bavarian accent, citizens of Munich pronounced ‘Einbeck’ as ‘ein Bock’ (a billy goat), and thus the beer became known as ‘Bock.’ A goat often appears on bottle labels.” And presumably because they were special releases, many breweries went all out promoting them with beautiful artwork on posters and other advertising.

Sunday’s ad is for Frankenmuth Bock Beer, though primarily for their Mellow-Dry Beer, which was published on June 29, 1951. This one was for the Frankenmuth Brewing Co. of Frankenmuth, Michigan, which was originally founded in 1862, and is still going strong today. This ad ran in the Bay City Times, of Bay City, Michigan. The spokesperson in the ad is “Eleanor Scotty, popular television star.” If you’ve never heard of her, you’re not alone, and there is surprisingly little about her online for a “popular television star.” The only mention I could find was that she appeared on ‘The Scotti Show,’ a musical comedy program starring popular Detroit nightclub entertainers George and Eleanor Scotti.”