Today is the birthday of Samuel Whitbread II (January 18, 1764-July 6, 1815). Despite being the son of Whitbread Brewery founder Samuel Whitbread, he is most remember for being a politician. According to Wikipedia:

Whitbread was born in Cardington, Bedfordshire, the son of the brewer Samuel Whitbread. He was educated at Eton College, Christ Church, Oxford and St John’s College, Cambridge, after which he embarked on a European ‘Grand Tour’, visiting Denmark, Sweden, Russia, Poland, Prussia, France and Italy. He returned to England in May 1786 and joined his father’s successful brewing business.

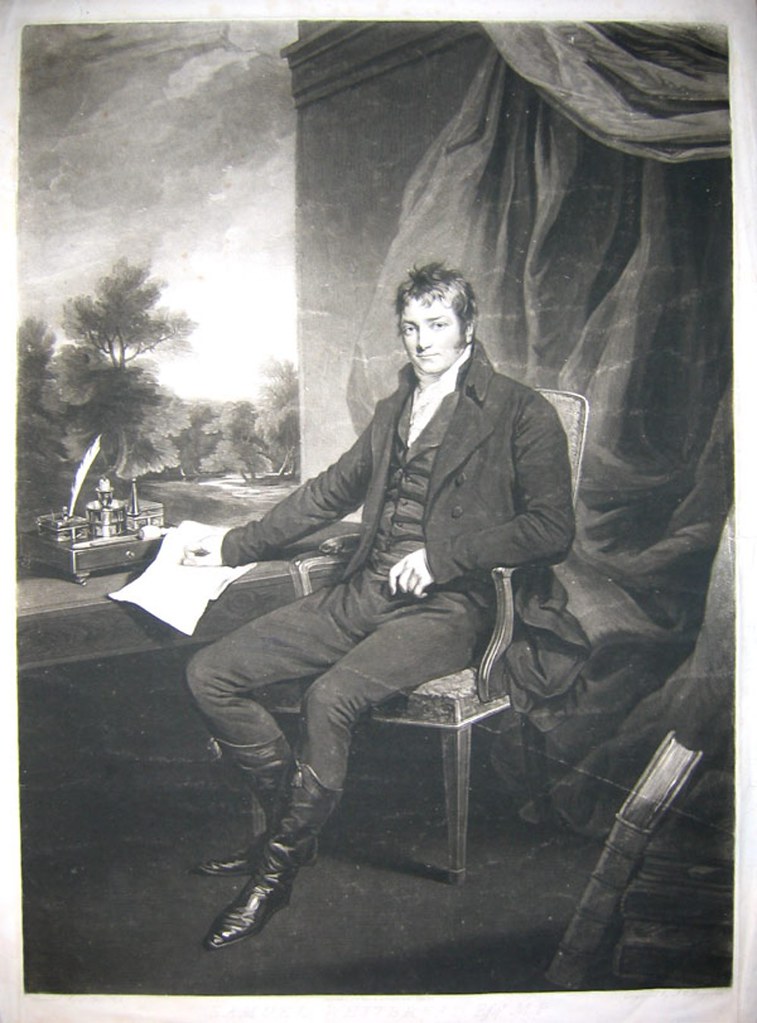

“Samuel Whitbread Esqr. M.P.” by Samuel William Reynolds after John Opie, 1804. This is the painting’s description. “A fine full length, seated portrait of the brewer, philanthropist and Whig politician Samuel Whitbread (1758-1815). He sits at his desk, wearing a dark suit and hessian boots, before an open window, his hand resting on a piece of paper. In the background is a draped curtain and on the floor is a pile of books.”

For over two decades he was a Member of Parliament:

Whitbread was elected Member of Parliament for Bedford in 1790, a post he held for twenty-three years. Whitbread was a reformer — a champion of religious and civil rights, for the abolition of slavery, and a proponent of a national education system. He was a close friend and colleague of Charles James Fox. After Fox’s death, Whitbread took over the leadership of the Whigs, and in 1805 led the campaign to have Henry Dundas, 1st Viscount Melville, removed from office.

Whitbread admired Napoleon and his reforms in France and Europe. He hoped that many of Napoleon’s reforms would be implemented in Britain. Throughout the Peninsular War he played down French defeats convinced that sooner or later Napoleon would triumph, and he did all he could to bring about a withdrawal of Britain from the continent. When Napoleon abdicated in 1814 he was devastated. Whitbread began to suffer from depression, and on the morning of 6 July 1815, he committed suicide by cutting his throat with a razor.

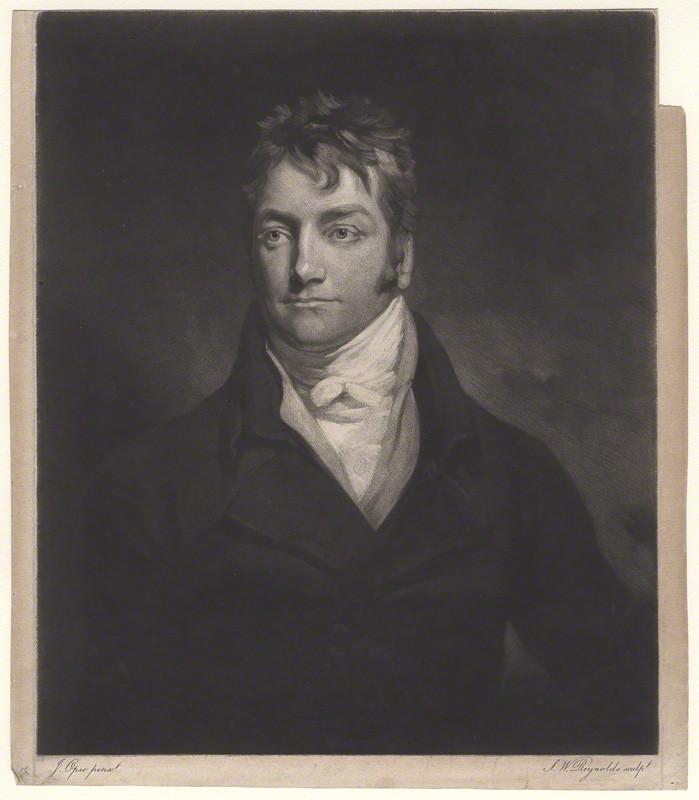

This portrait of Whitbread was done in 1806.

Bedfordshire Genealogy and History has a fuller biography of Samuel Whitbread 2nd:

Samuel Whitbread, the son of the brewer Samuel Whitbread, and Harriet Hayton, was born in Cardington, Bedfordshire in 1758. His mother died when he was a child and his father took great care over his only son. When Samuel was sent to Eton he was accompanied by his own private tutor. Samuel continued his education at Christ Church, Oxford and St. John’s College, Cambridge, where he met his lifelong friend, Charles Grey.

After university Samuel Whitbread sent his son on a tour of Europe, under the guidance of the historian, William Coxe. This included visits to Denmark, Sweden, Russia, Poland, Prussia, France and Italy. When Samuel returned in May 1786, he joined his father running the extremely successful family brewing business.

In 1789 Samuel Whitbread married Elizabeth Grey, the sister of Charles Grey. The two men were deeply interested in politics. Grey was already MP for Northumberland and in 1790 Whitbread was elected MP for Bedford. In the House of Commons, Whitbread and Grey became followers of Charles Fox, the leader of the Radical Whigs.

Whitbread soon emerged in Parliament as a powerful critic of the Tory Prime Minister, William Pitt. A passionate supporter of reform, Whitbread argued for an extension of religious and civil rights, an end to the slave-trade, and the establishment of a national education system.

In April 1792, Whitbread joined with a group of pro-reform Whigs to form the Friends of the People. Three peers (Lord Porchester, Lord Lauderdale and Lord Buchan) and twenty-eight Whig MPs joined the group. Other leading members included Charles Grey, Richard Sheridan, Major John Cartwright, Lord John Russell,George Tierney, and Thomas Erskine. The main objective of the the society was to obtain “a more equal representation of the people in Parliament” and “to secure to the people a more frequent exercise of their right of electing their representatives”. Charles Fox was opposed to the formation of this group as he feared it would lead to a split the Whig Party.

On 30th April 1792, Charles Grey introduced a petition in favour of constitutional reform. He argued that the reform of the parliamentary system would remove public complaints and “restore the tranquillity of the nation”. He also stressed that the Friends of the People would not become involved in any activities that would “promote public disturbances”. Although Charles Fox had refused to join the Friends of the People, in the debate that followed, he supported Grey’s proposals. When the vote was taken, Grey’s proposals were defeated by 256 to 91 votes.

In 1793 Samuel Whitbread toured the country making speeches on the need for parliamentary reform. He encouraged people to sign petitions at his meetings and when he returned to London they were presented to Parliament. Whitbread also campaigned on behalf of agricultural labourers. In the economic depression of 1795, Whitbread advocated the payment of higher wages. When Whitbread introduced his minimum wage bill to the House of Commons in December 1795 it was opposed by William Pitt and his Tory government and was easily defeated.

Whitbread was a strong supporter of a negotiated peace with France and supported Fox’s calls to send a government minister to Paris. Whitbread argued for Catholic Emancipation and opposed the act for the suppression of rebellion in Ireland. His friend, Samuel Romilly, said that Whitbread was “the promoter of every liberal scheme for improving the condition of mankind, the zealous advocate of the oppressed, and the undaunted opposer of every species of corruption and ill-administration.”

In 1807 Samuel Whitbread proposed a new Poor Law. His scheme not only involved an increase in the financial help given to the poor, but the establishment of a free educational system. Whitbread proposed that every child between the ages of seven and fourteen who was unable to pay, should receive two years’ free education. The measure was seen as too radical and was easily defeated in the House of Commons.

Whitbread refused to be disillusioned by his constant defeats and during the next few years he made more speeches in the House of Commons than any other member. Sometimes his attacks on George III and his ministers were considered to be too harsh, even by his closest political friends.

Unable to persuade Parliament to accept his ideas, Whitbread used his considerable fortune (his father, Samuel Whitbread had died in 1796) to support good causes. Whitbread gave generous financial help to establish schools for the poor. An advocate of the monitorial system developed by Andrew Bell and Joseph Lancaster, he helped fund the Royal Lancasterian Society that had the objective of establishing schools that were not controlled by the Church of England.

When the Whigs gained power in 1806, Whitbread expected the Prime Minister, Lord Grenville, to offer him a place in his government. He was deeply disappointed when this did not happen. Some claimed it was because Whitbread was too radical. Others suggested it was due to snobbery and the aristocrats in the party disapproved of a tradesman entering the cabinet.

After this rejection, Whitbread consoled himself with his involvement in the Drury Lane Theatre. In 1809 the theatre was destroyed by fire. Already over £500,000 in debt, the theatre was in danger of going out of business. Whitbread became chairman of the committee set up to rebuild the theatre. With the help of his political friends, Whitbread managed to raise the necessary funds and the Drury Lane Theatre was reopened on 10th October, 1812.

In 1815 Whitbread began to suffer from depression. Over the years he had been upset by the way he was portrayed by the political cartoonists such as, James Gillray and George Cruikshank. He also began to worry about the brewery business and the way he was treated in the House of Commons. After one debate in June he told his wife: “They are hissing me. I am become an object of universal abhorrence.” On the morning of 6th June 1815, Samuel Whitbread committed suicide by cutting his throat with a razor.

And if that’s not enough, the “Dictionary of National Biography, 1885-1900, Volume 61” also includes a biography and Encyclopedia.com has an overview of the company, as does AIM25.

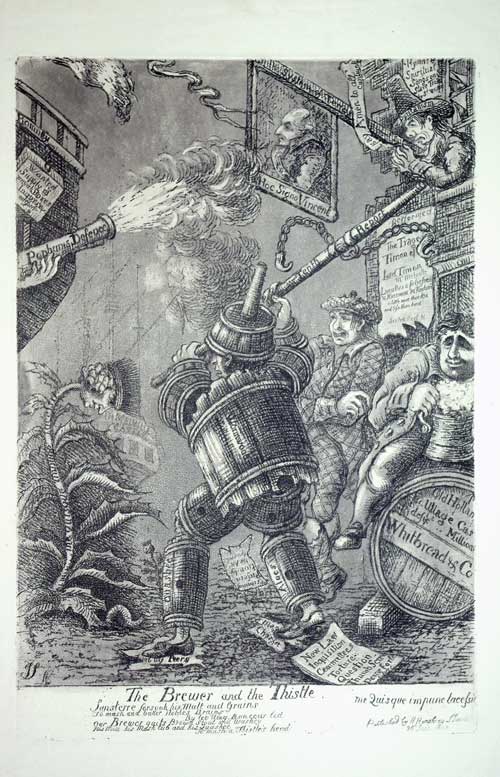

This is a political cartoon featuring Samuel Whitbread entitled “The Brewer and the Thistle.” It was drawn by James Sayers, and published by Hannah Humphrey, June 26, 1805. The people in the cartoon include Charles James Fox (1749-1806), James Maitland Lauderdale (1759-1839), William Wilberforce (1759-1833), Sir Home Riggs Popham (1762-1820), Samuel Whitbread (1758-1815) and Henry Dundas Melville (1742-1811). While I’m sure you need to be a historian specializing in this period of British history, the Royal Collection Trust gives this description. “Whitbeard in costume of beer casks, attacks thistle with Melville’s head. (r) alehouse; Fox and Launderdale (in tartan) laugh. Wilberforce leans out of window dressed as Puritan. (l) blunderbuss fired at sign of St. Vicent.”

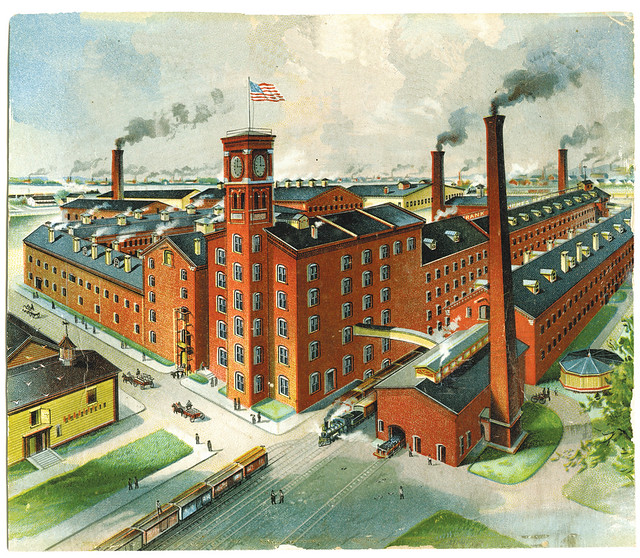

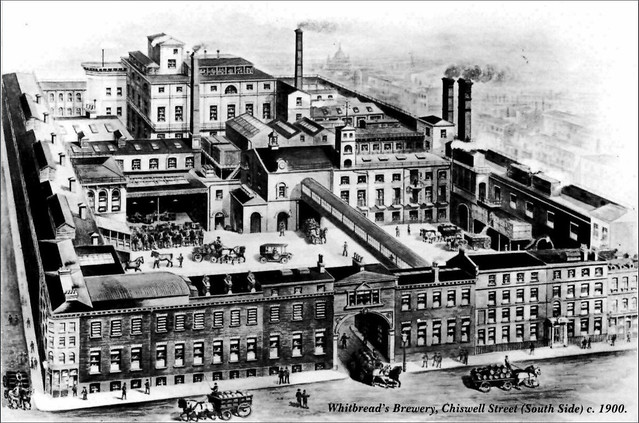

Finally, here’s the Whitbread Brewery on Chiswell Street in London as it appeared around 1900.

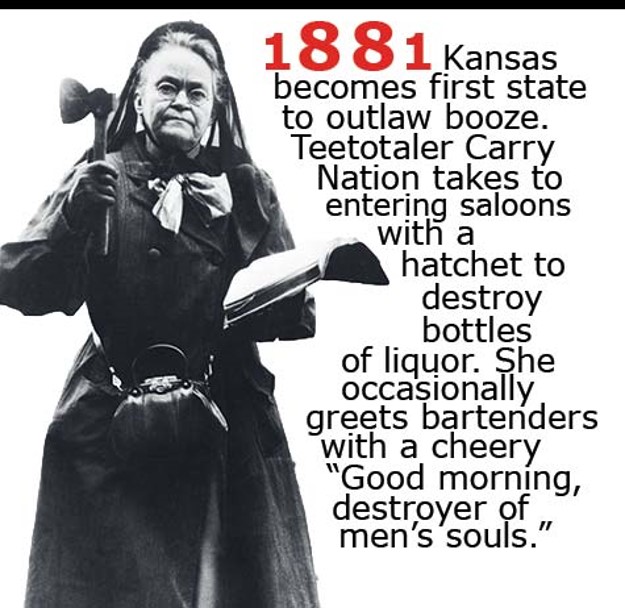

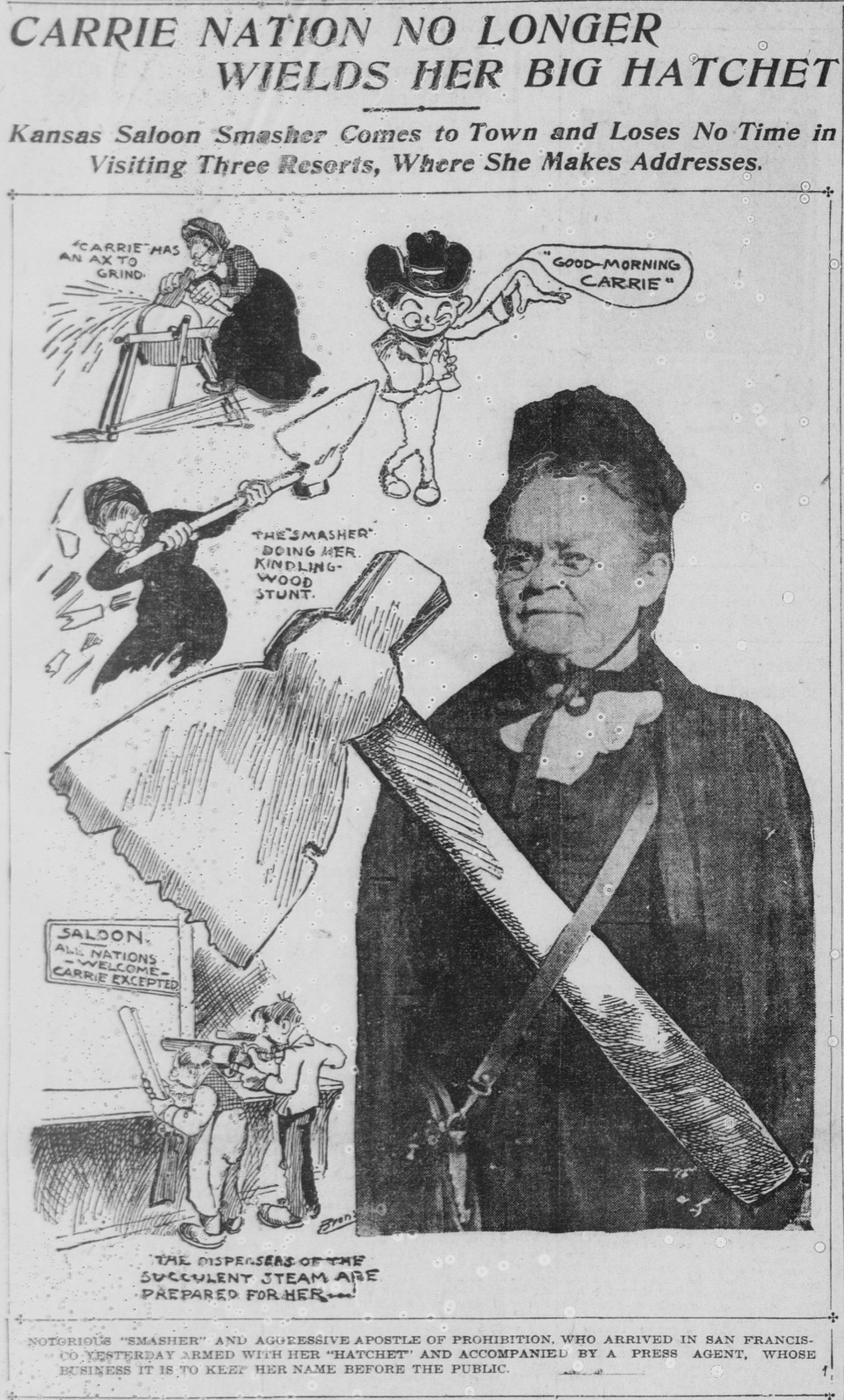

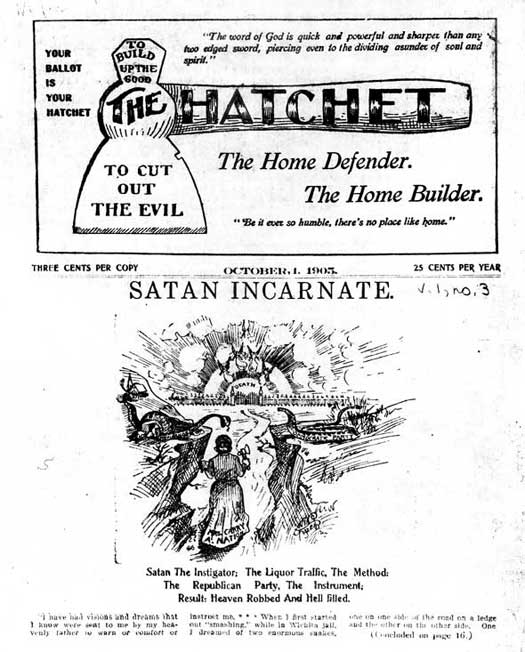

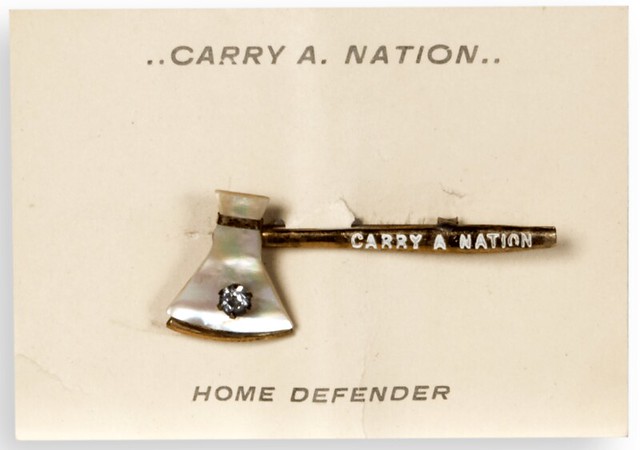

She even sold hatchet pins.

She even sold hatchet pins. A common sight in bars and taverns at the time.

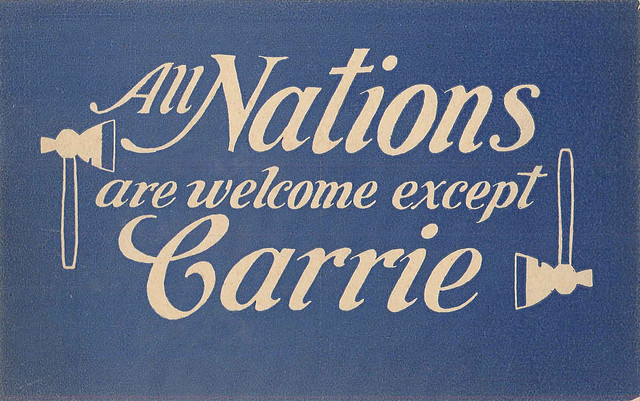

A common sight in bars and taverns at the time.