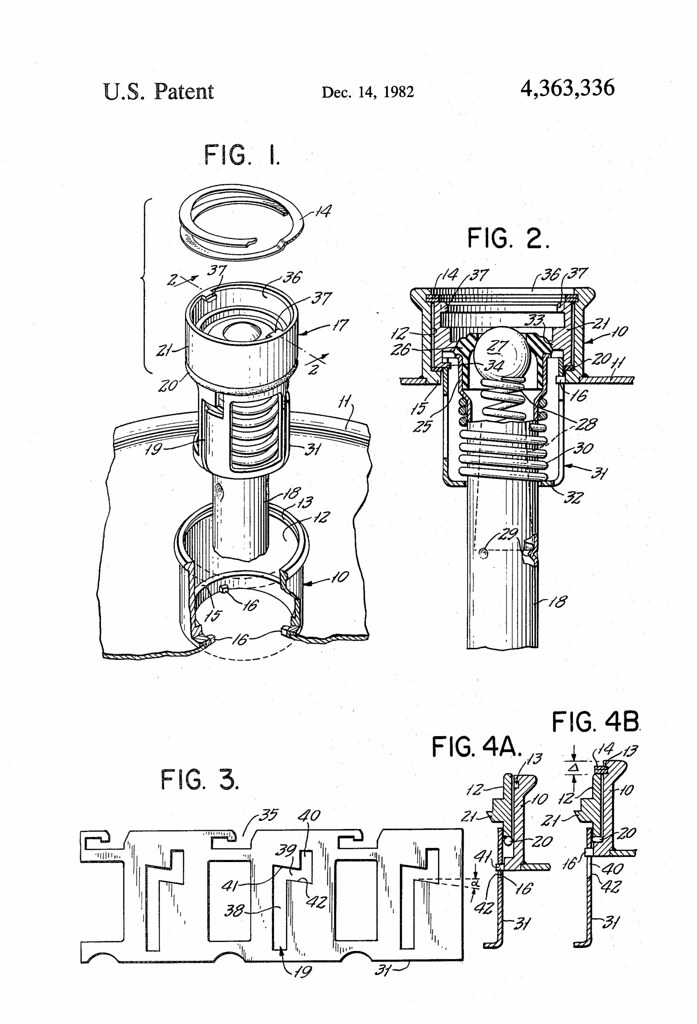

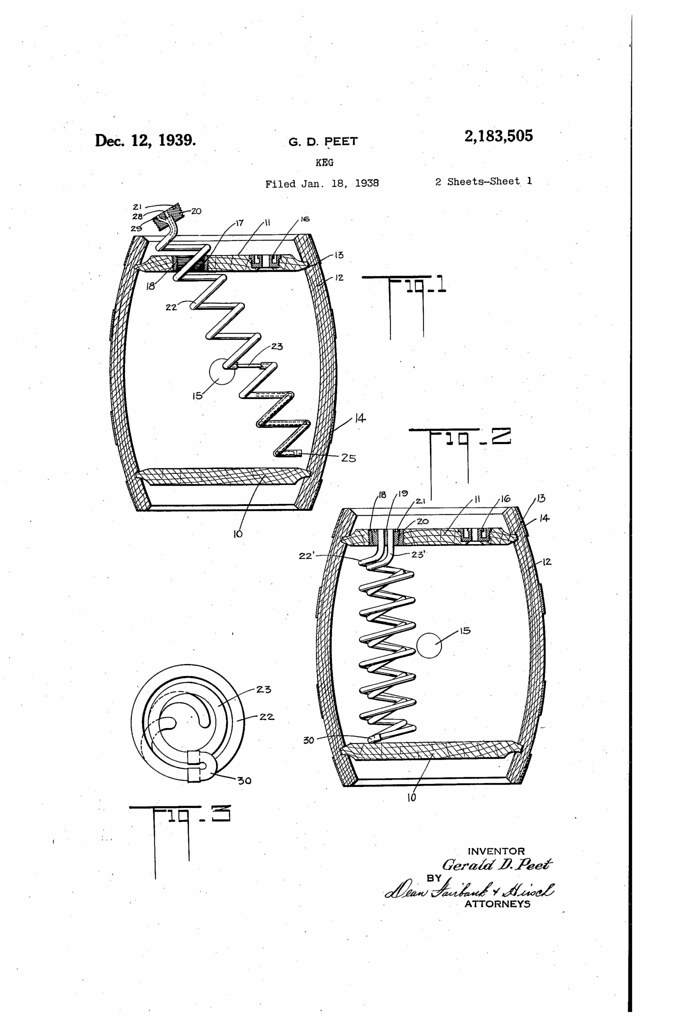

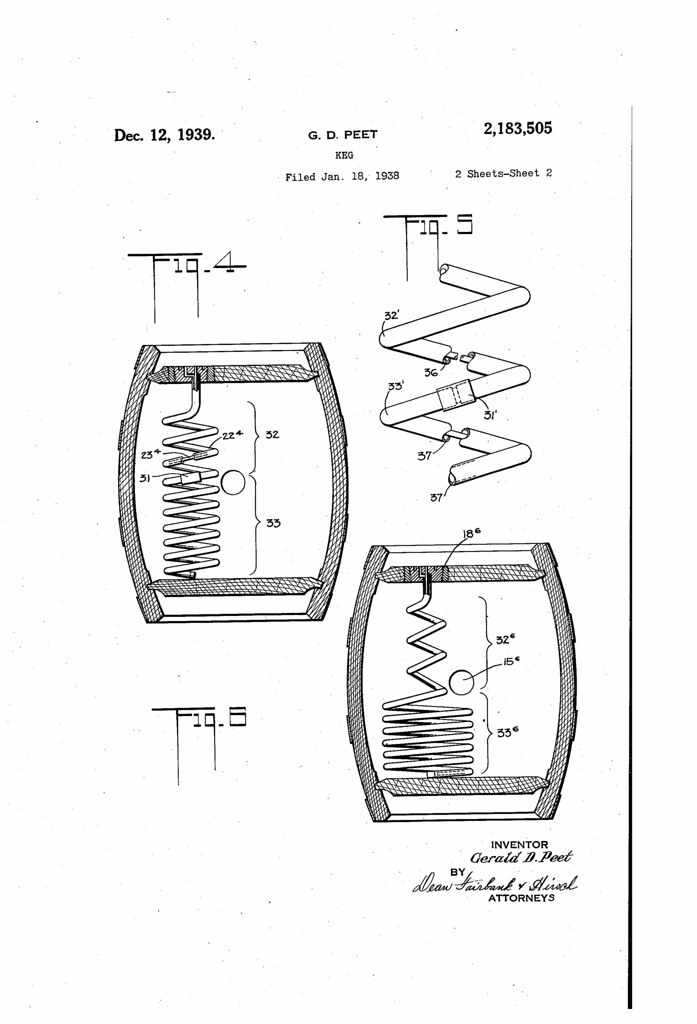

Today in 1982, US Patent 4363336 A was issued, an invention of Vincent J. Cerrato, for his “Keg-Tapping Structure.” Here’s the Abstract:

The invention contemplates removable structure to facilitate keg-tapping, and pressurized dispensing of liquid contents of the keg. A so-called Barnes neck forms part of the keg and has a bore with an elastomeric ring seal and flange at its lower end, and a valve-and-tube subassembly is inserted through the neck, to the point of valve-body compression of the seal, when secured by a removable retaining ring. In the course of such insertion, one or more radially inward lugs on the neck flange track corresponding slot formations in the subassembly. Each such slot formation has a first upward longitudinal course, leading to an angular bayonet-like offset course, and then to a second upward longitudinal course. The location of the angular offset is such that the valve body cannot compressionally load the seal ring in the absence of the partial rotation needed to develop lug alignment with the second upward longitudinal course.