Today in 1999, US Patent EP 0668347 B1 was issued, an invention of Martin Widhopf, assigned to Anton Steinecker Entwicklungs GmbH, for his “Pan For Boiling Wort During Beer Production.” There’s no Abstract, although in the description it includes this summary:

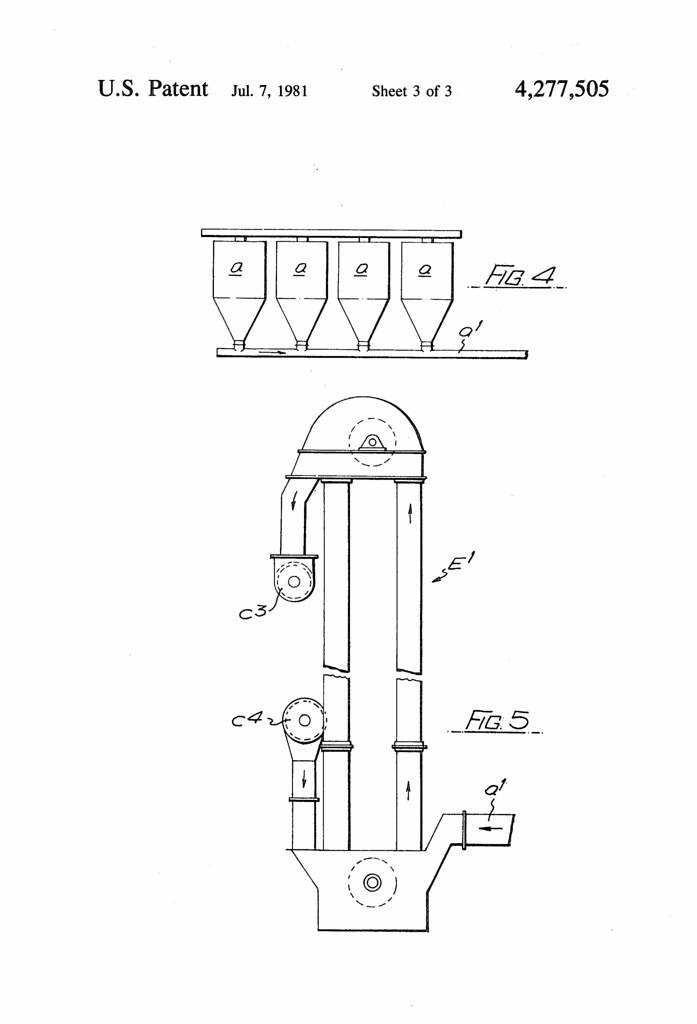

A wort kettle for boiling wort for brewing, comprising a vapor escape pipe and a vapor compressor, wherein vapor can escape to the outside via said vapor escape pipe during heating of said wort kettle and can be diverted by means of a shut-off device via said vapor compressor during boiling, characterized in that said shut-off device is formed by a surge tank which is arranged in the flow direction of said vapor in said vapor escape pipe after a branch towards said vapor compressor.