![]()

Today is the birthday of William IV, Duke of Bavaria (November 13, 1493-March 7, 1550). William IV “was Duke of Bavaria from 1508 to 1550, until 1545 together with his younger brother Louis X, Duke of Bavaria. He was born in Munich to Albert IV and Kunigunde of Austria, a daughter of Emperor Frederick III.”

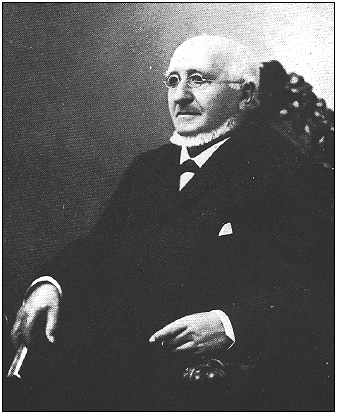

Portrait by Barthel Beham.

Though his father had determined the everlasting succession of the firstborn prince in 1506, his younger brother Louis refused a spiritual career with the argument that he was born before the edict became valid. With support of his mother and the States-General, Louis forced William to accept him as co-regent in 1516. Louis then ruled the districts of Landshut and Straubing, in general in concord with his brother.

William initially sympathized with the Reformation but changed his mind as it grew more popular in Bavaria. In 1522 William issued the first Bavarian religion mandate, banning the promulgation of Martin Luther’s works. After an agreement with Pope Clement VII in 1524 William became a political leader of the German Counter reformation, although he remained in opposition to the Habsburgs since his brother Louis X claimed the Bohemian crown. Both dukes also suppressed the peasant uprising in South Germany in an alliance with the archbishop of Salzburg in 1525.

The conflict with Habsburg ended in 1534 when both dukes reached an agreement with Ferdinand I in Linz. William then supported Charles V in his war against the Schmalkaldic League in 1546. William’s chancellor for 35 years was the forceful Leonhard von Eck.

William was a significant collector and commissioner of art. Among other works he commissioned an important suite of paintings from various artists, including the Battle of Issus by Albrecht Altdorfer. This, like most of William’s collection, is now housed in the Alte Pinakothek in Munich. With his order to expand the Neuveste with the so-called Rundstubenbau and to set up the first Court Garden began the history of the Munich Residence as a representative palace. To the history cycle of the garden pavilion belonged Albrecht Altdorfer’s painting. In 1546 he ordered to upgrade Dachau Palace from a Gothic ruin into a renaissance palace. In 1523 with the appointment of Ludwig Senfl began the rise of the Bavarian State Orchestra.

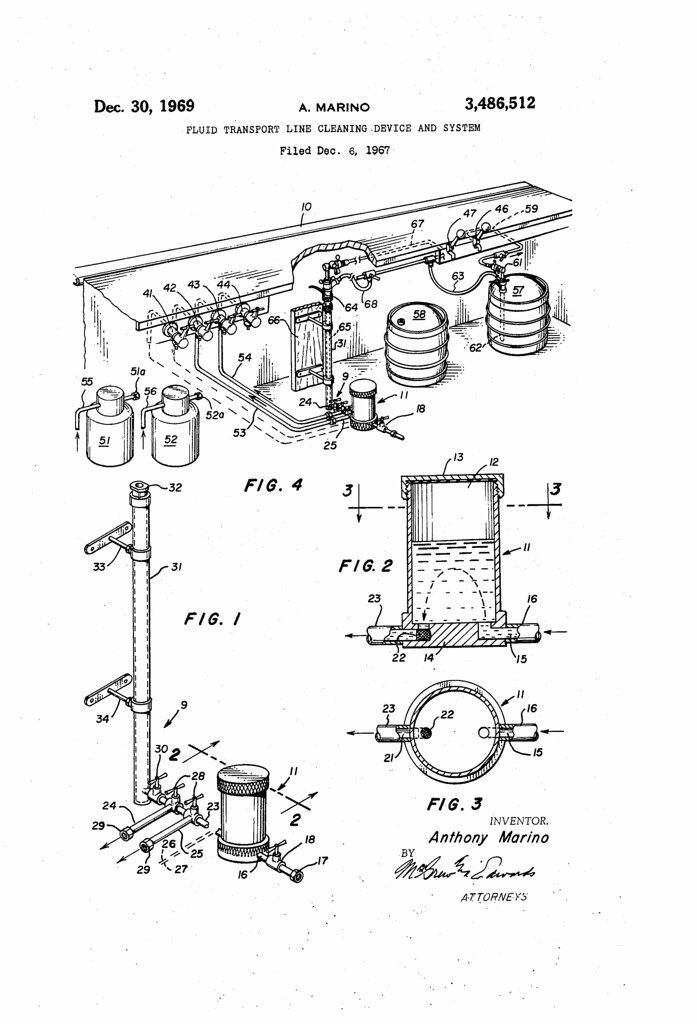

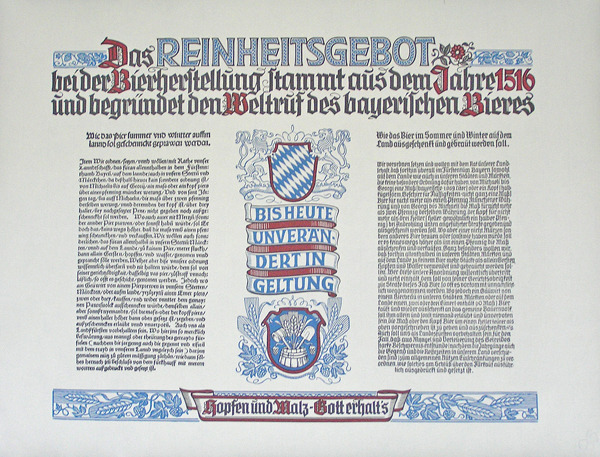

On 23 April 1516, before a committee consisting of gentry and knights in Ingolstadt, he issued his famous purity regulation for the brewing of Bavarian Beer, stating that only barley, hops, and water could be used. This regulation remained in force until it was abolished as a binding obligation in 1986 by Paneuropean regulations of the European Union.

William died in 1550 in Munich and was succeeded by his son Albert. He is buried in the Frauenkirche in Munich.

Duke Wilhelm IV of Bavaria by Hans Schwab von Wertinger.

William IV, Duke of Bavaria, wrote and signed the Reinheitsgebot, also known as the Bavarian Beer Purity Law, and later the German Beer Purity Law.

In the Bavarian town of Ingolstadt on April 23, 1516, William IV, Duke of Bavaria wrote and signed the law, along with his younger brother Louis X, Duke of Bavaria. That 1516 law was itself a variation of earlier laws, at least as early as 1447 and another in independent Munich in 1487. When Bavaria reunited, the new Reinheitsgebot applied to the entirety of the Bavarian duchy. It didn’t apply to all of Germany until 1906, and it wasn’t referred to as the Reinheitsgebot until 1918, when it was coined by a member of the Bavarian parliament.

Another painting by Barthel Beham.