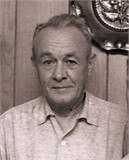

Today is the birthday of George Michael Biner (February 22, 1897-June 19, 1971). He was the brother of William H. Biner, who was also a brewer. He was born in the Montana territory to Swiss immigrant parents. His father, Theophil Biner, knew Leopold Schmidt and even worked at his Olympia Brewery. Biner sent both of his sons, including George, to brewing school in Milwaukee.

This short biography is from his Find-a-Grave page:

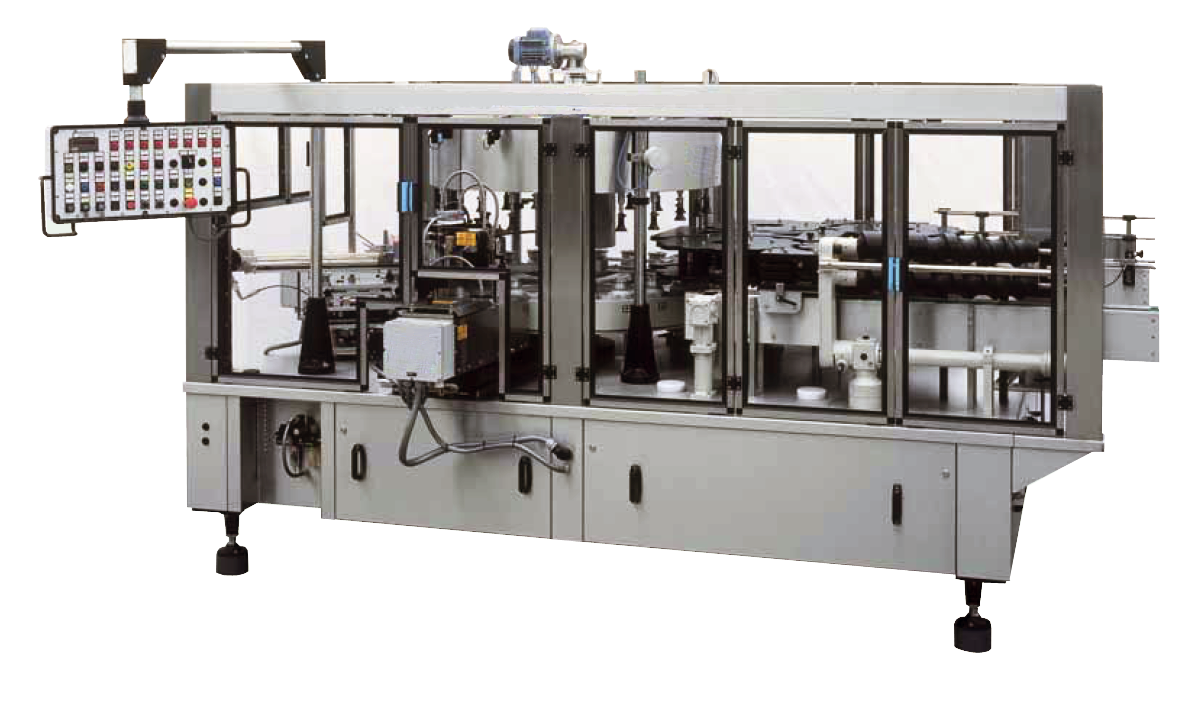

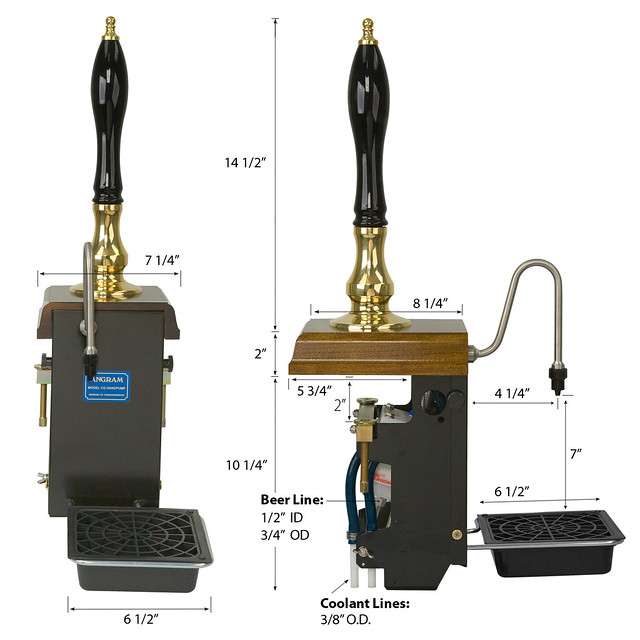

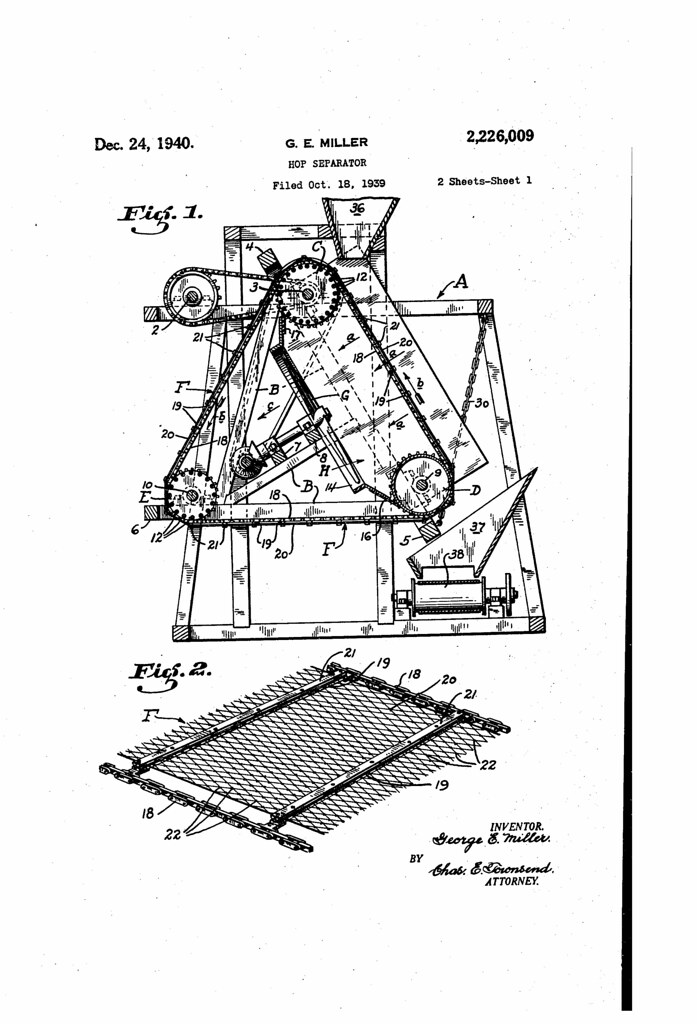

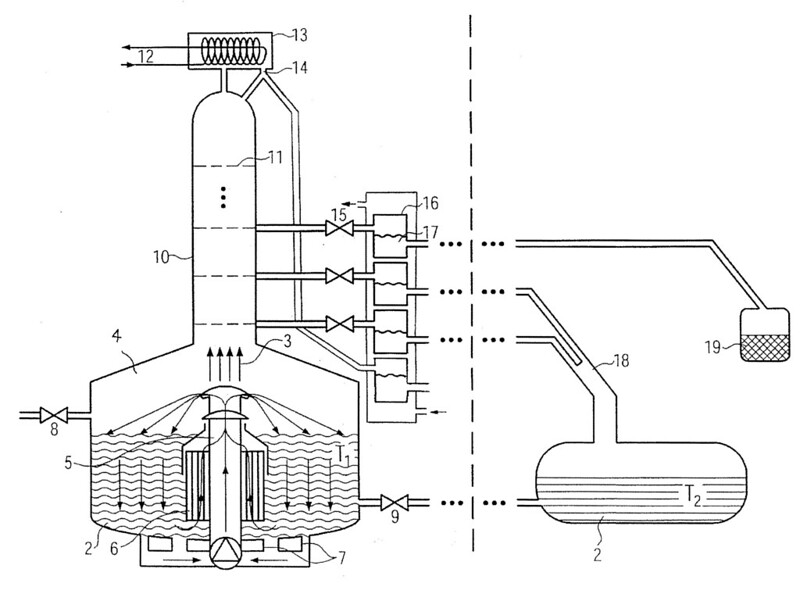

George Michael Biner (1897-1971) was the son of Theophil Biner and Juliana Truffer. George contracted polio as a soldier during World War I. However, he went on to be a successful artist, brew master and inventor. He supervised the laying of the tile for the dome of the Los Angeles County Library, invented a labeling machine for breweries and was the co-founder of Biner Ellison which pioneered the production of liquid filling machines, and still makes brewery equipment today.