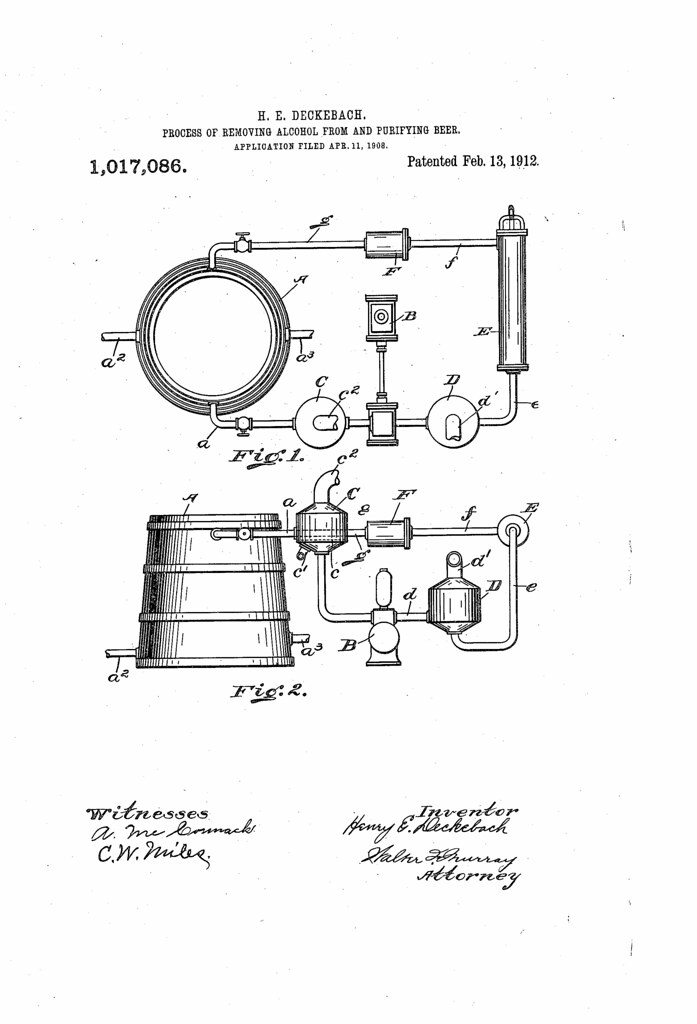

Today in 2014, US Patent 20140072691 A1 was issued, an invention of Ludwig Scheller, Rudolf Michel, and Patrick Bahns, for their “Method and Device for Adding Hops in Beer Manufacture, and Also Hop Product.” Here’s the Abstract:

The invention relates to a method for adding hops in beer manufacture, having the following process steps; a) separation of a sub-quantity (07 a) of water and/or wort (07) and/or beer as an aqueous fluid, b) addition of hop extract (10) in liquid or pasty form to the separated aqueous fluid (07 a), c) production of a macroemulsion (13) of the hop extract by emulsifying the hop extract (10) in the aqueous fluid (07 a), d) increasing the pressure in the macroemulsion (13) of the hop extract to a feed pressure of in particular higher than 100 bar, e) production of a microemulsion (17) of the hop extract by feeding the pressurized macroemulsion (13) through a gap or a valve (16) or by feeding the pressurized macroemulsion against a baffle plate, f) at least partial return of the microemulsion (17) of the hop extract to the beer manufacturing process.