Today in 1971, US Patent 3607298 A was issued, an invention of Robert O. V. Lloyd and William Mitchell Hatfield, assigned to Bush Boake Allen Ltd., for his “Hop Concentrates.” There’s no Abstract, although in the description it includes these claims:

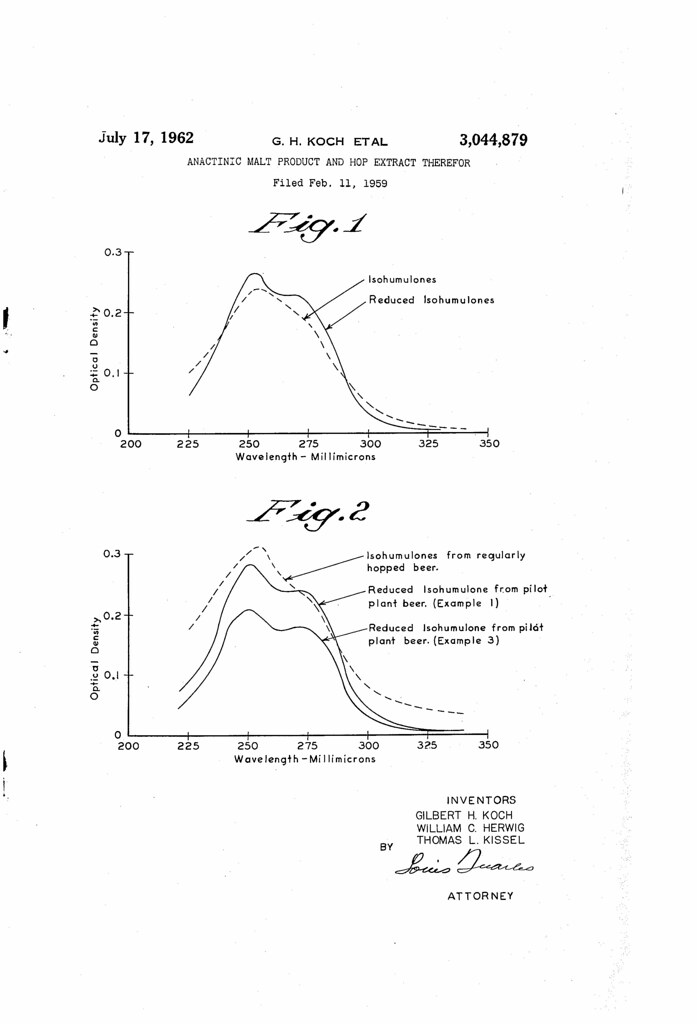

The present invention relates to hop extracts, including isomerized hop extracts and to processes for their production.

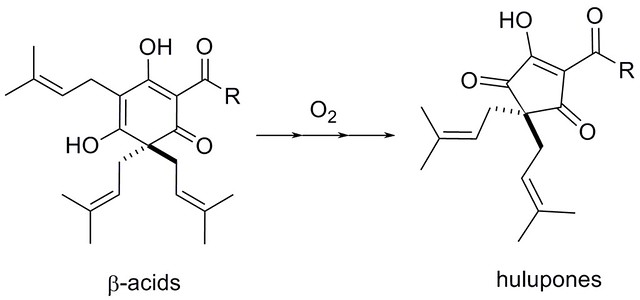

Hops contain, among other things: soft and hard resins including such weakly acidic compounds as humulones (e.g. humulone, cohumulone and adhumulone) and lupulones; essential oils which are those relatively volatile oils which contribute to the characteristic odor of hops; fixed oils, which are contained in the hop seeds and are not readily distilled or extracted by hot water; and water-soluble material such as tannins and proteins.

In the traditional brewing process hops are boiled with wort, which is an aqueous solution of malt sugars. As a consequence of the boiling, a variety of resins and oils pass into the wort. Of these the most important are the humulones, which on boiling are partially isomerized to form water-soluble isohumulones. It is believed that the isohumulones are the principle bittering agent present in the finished beer, but a very large number of other compounds of widely differing chemical nature are also present in traditional beer and contribute to its properties. in the traditional process only a small proportion of the humulones present in the hops are isomerized and taken into solution. Further disadvantages of the traditional method are the need to store a large bulk of hops, which are liable to deteriorate, and the variability of flavor between batches.

The extraction of hops by solvents to give hop extracts which can be used to replace or augment hops in the brewing of beers and ales has received considerable attention for many years. This problem has attracted increased attention during the last l years because of the development in the chemistry of hop constituents and because the brewing industry has become rather less conservative in its attitude toward changes in materials and methods.